Zirconium oxide false tooth with bioactivity

A bioactive, zirconia technology, applied in the field of biomedical engineering materials, can solve problems such as no biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

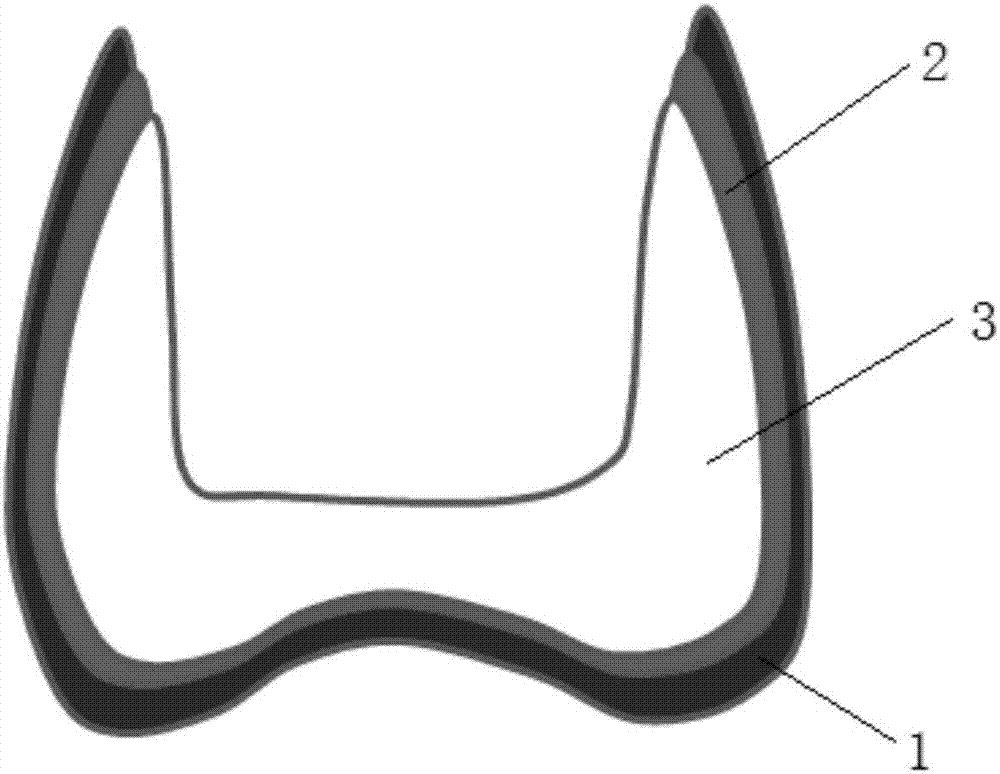

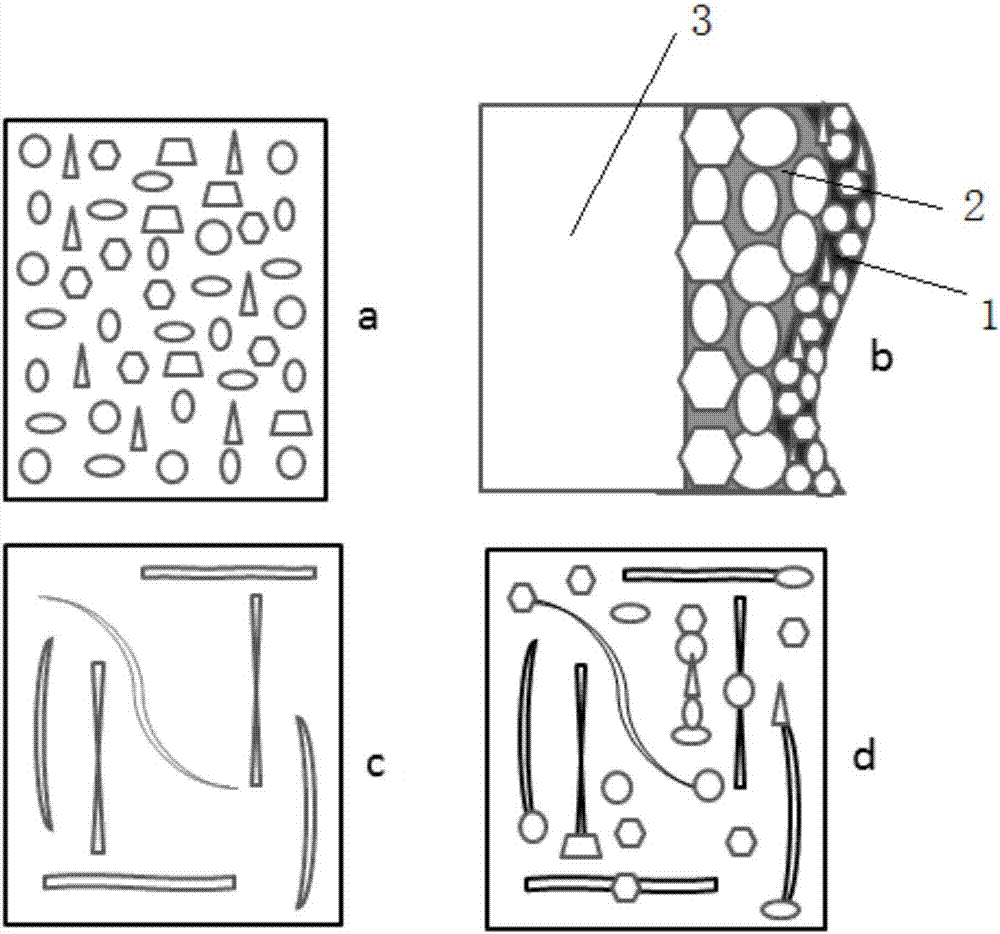

[0047] Such as figure 1 The bioactive zirconia denture shown has a gradient structure, which includes a bioactive outer surface layer and a matrix structure layer in sequence from the occlusal outer surface to the bonding inner surface, and the bioactive outer surface layer consists of the outer The nanoporous layer is composed of nanoporous layer and the inner microporous layer. The nanoporous layer is composed of zirconia nanocrystal grains and several nanopores penetrating the nanoporous layer. The microporous layer is composed of zirconia nanocrystal grains and several micropores penetrating the microporous layer. (Nanopore, micropore structure see figure 2 ), the matrix structure layer is composed of the outer dense zirconia nano-grain layer and the inner dense zirconia micro-grain layer, the interface between the nanoporous layer and the microporous layer forms a uniform gradient transition, the microporous layer and the matrix structure layer The interface between the...

manufacture example A

[0072] 4.1.1 Y (2-6mol%) partially stabilizes ZrO 2 Manufacture example A is as follows: adopt the method for reverse dripping to prepare Y partially stabilized ZrO 2 Slurry, the prepared precipitant NH 4 HCO 3 (10-50%) + NH 3 ·H 2 The O solution is placed in an Erlenmeyer flask, and the Erlenmeyer flask is placed in a magnetic stirrer or a stirred constant temperature water bath reactor, and the prepared Y-containing 3+ 、Zr 4+ The mother liquor includes zirconium hydroxide (ZrO(OH) 2 •nH 2 O≥99%), zirconium oxychloride (ZrOCl 2 •8H 2 O≥99%), zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O≥99%) one of them; yttrium nitrate Y (NO 3 ) 3 ·6H 2 O, yttrium chloride (YCI 3 ·6H 2O≥99.99%); slowly drop into the precipitant, and stir vigorously to make it fully react, after the reaction is completed, age for more than 8-12 hours, use a centrifuge to quickly separate, and vacuum filter the precipitate, and use Wash with distilled water and ethanol, and dry at 100-200°C for 1-2 h...

manufacture example B

[0073] 4.1.2. Y (2-6mol%) partially stabilizes ZrO 2 Manufacture example B is as follows: the Zr that concentration is 0.5-1mol / L 4+ Zirconium hydroxide (ZrO(OH) 2 •nH 2 (O≥99%) suspension was added to the reactor, and then yttrium oxide was added to the reactor in 3 to 5 times. Heat the reactor to 40-60°C and keep it warm for 2-3 hours. After the added yttrium oxide is completely dissolved, add polyvinyl alcohol with 0.5-1wt% zirconium hydroxide weight, then heat it to 200-250°C and keep it warm for 55- The hydrothermal-hydrolysis reaction was carried out for 65 hours. Keep the internal pressure at 2-3MPa to gradually hydrolyze and precipitate. Use a centrifuge to separate quickly, vacuum filter the precipitate, wash with distilled water and ethanol, and dry at 100-200°C for 1-2 hours to obtain the Y part of the stable ZrO 2 Powder B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com