Treatment system and method of township domestic wastewater

A domestic sewage and treatment system technology, applied in the direction of biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult operation and maintenance, short construction period, low operating cost, etc., to achieve The effect of reducing early equipment investment and operating electricity costs, high degree of solid-liquid separation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

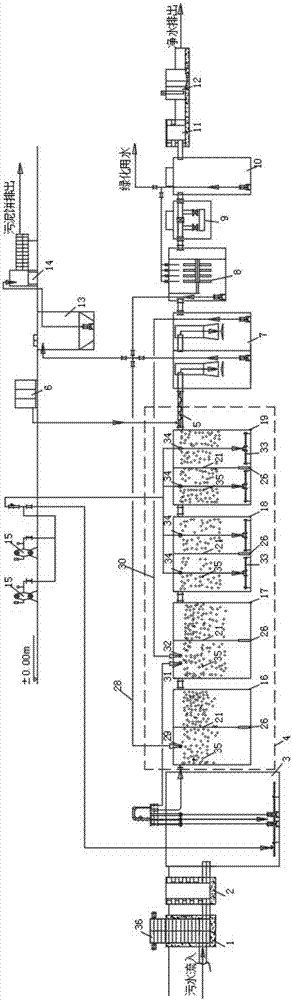

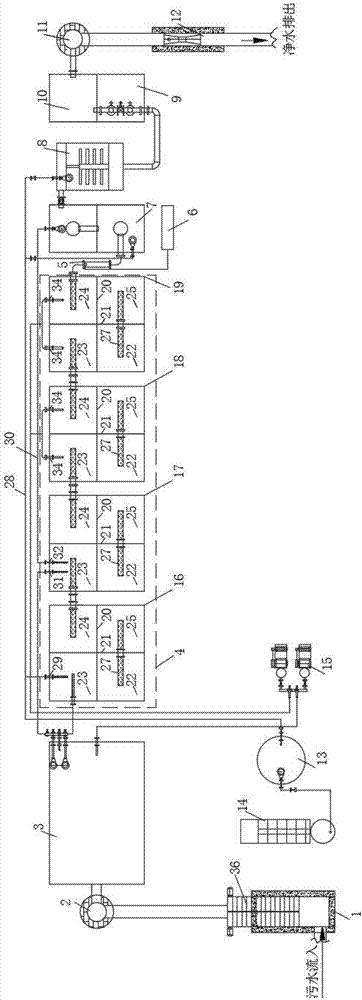

[0063] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

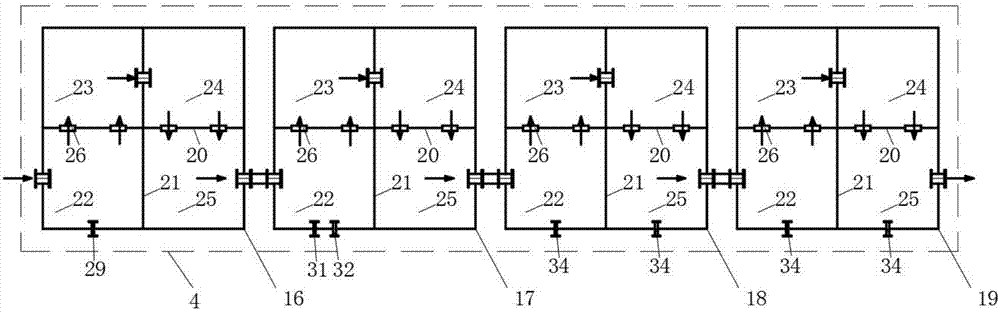

[0064] Such as Figure 1-3 As shown, a township domestic sewage treatment system includes a slag removal tank 1, a grit chamber 2, a lifting tank 3, a multi-stage moving bed biofilm reactor 4, a pipeline mixer 5, a fully automatic dosing machine 6, a sedimentation tank Pool 7, filter 8, sterilizer 9, reuse water storage tank 10, secondary grit chamber 11, Pasteur metering tank 12, sludge storage tank 13, sludge dehydrator 14 and fan 15;

[0065] The multi-stage moving bed biofilm reactor 4 includes 4 tank bodies connected in series successively, which are respectively anaerobic tank 16, anoxic tank 17, primary aerobic tank 18, and secondary aerobic tank 19, each of which The tank bodies are all rectangular parallel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com