Preparation method of high-water-absorbing resin with broad-spectrum antibacterial property

A super absorbent resin, broad-spectrum antibacterial technology, applied in the field of super absorbent resin preparation, can solve the problems of easy elution, easy shedding, poor heat resistance of organic antibacterial agents, etc., to improve antibacterial ability, overcome easy discoloration, high The effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a superabsorbent resin with broad-spectrum antibacterial properties, comprising the following steps:

[0035] (1) Acrylic acid, cross-linking agent and water carry out polymerization reaction under the initiation of initiator to obtain resin colloid.

[0036] This step is a polymerization reaction step, and the final product is resin colloid. In order to ensure that the polymerization reaction proceeds smoothly, it can be carried out as follows:

[0037] (11) Mix acrylic acid and water to adjust the pH of the acrylic acid solution to 6-7;

[0038] (12) cooling the acrylic acid solution to the initiation temperature, adding a crosslinking agent and an initiator after purging nitrogen to remove oxygen, and a polymerization reaction occurs, and the temperature of the system continues to rise;

[0039] (13) When the temperature of the system no longer rises, heat preservation treatment is carried out at the heat preservation t...

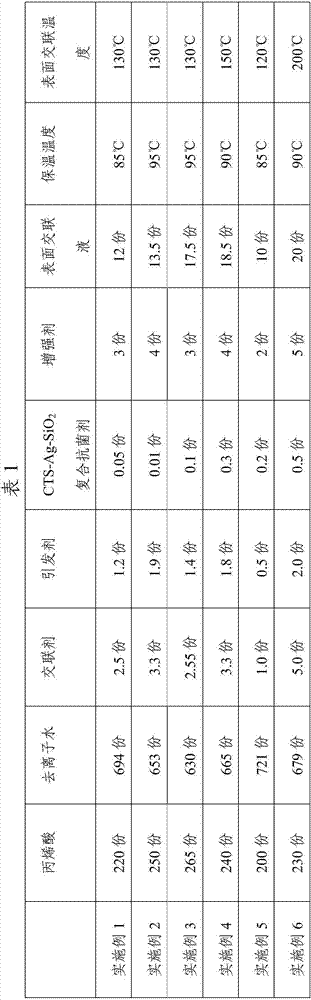

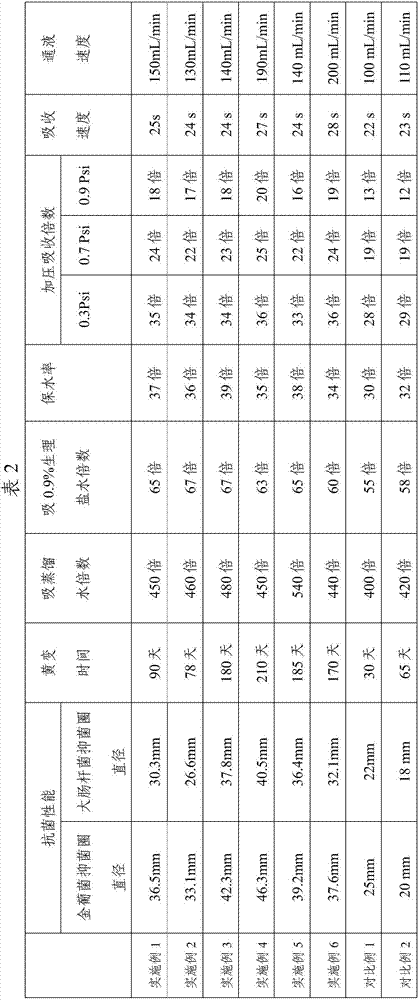

Embodiment 1

[0064] The weight parts of raw materials used are: 220 parts of acrylic acid, 86 parts of sodium hydroxide, 694 parts of deionized water, crosslinking agent: 2.5 parts of tetraallyloxyethane, initiator: 0.8 parts of potassium persulfate and 0.4 parts of sodium bisulfite Parts, reinforcing agent: 2 parts of aluminum sulfate and 1 part of silicon dioxide, surface crosslinking liquid: 8 parts of ethylene glycol and 4 parts of butanediol diglycidyl ether, CTS-Ag-SiO 2 0.05 part of compound antibacterial agent.

[0065] Among them, CTS-Ag-SiO 2 Composite antibacterial agent is prepared by the following method:

[0066] Prepare silver ammonia solution: take 0.1g silver nitrate solid, dissolve it with 55mL distilled water, add 1mol / L ammonia water to form a precipitate, continue to add ammonia water until the solution is transparent, then add potassium hydroxide solid until another precipitate forms, at this time the solution becomes Black, then add ammonia water until the solution...

Embodiment 2

[0078] The parts by weight of raw materials used are: 250 parts of acrylic acid, 97 parts of sodium hydroxide, 653 parts of deionized water, crosslinking agent: 3.3 parts of trimethylolpropane triacrylate, initiator: 1.2 parts of potassium persulfate and sodium bisulfite 0.7 parts, reinforcing agent: 2.5 parts of alumina and 1.5 parts of kaolin, surface cross-linking liquid: 10 parts of glycerol and 3.5 parts of polyglycidyl ether of polyglycerol, CTS-Ag-SiO 2 Composite antibacterial agent 0.01 part.

[0079] CTS-Ag-SiO 2 The preparation method of composite antibacterial agent is with embodiment 1.

[0080] The specific preparation process of superabsorbent resin is as follows:

[0081] S1:

[0082] Mix acrylic acid and water, neutralize the pH of the acrylic acid solution to 6.3 with sodium hydroxide;

[0083] Cool the acrylic acid solution to 25°C, add a crosslinking agent and an initiator to initiate a polymerization reaction after purging nitrogen to remove oxygen, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com