Sulfonated polyaryl ether ketone (SFPAEK) ion exchange membrane preparation method and application

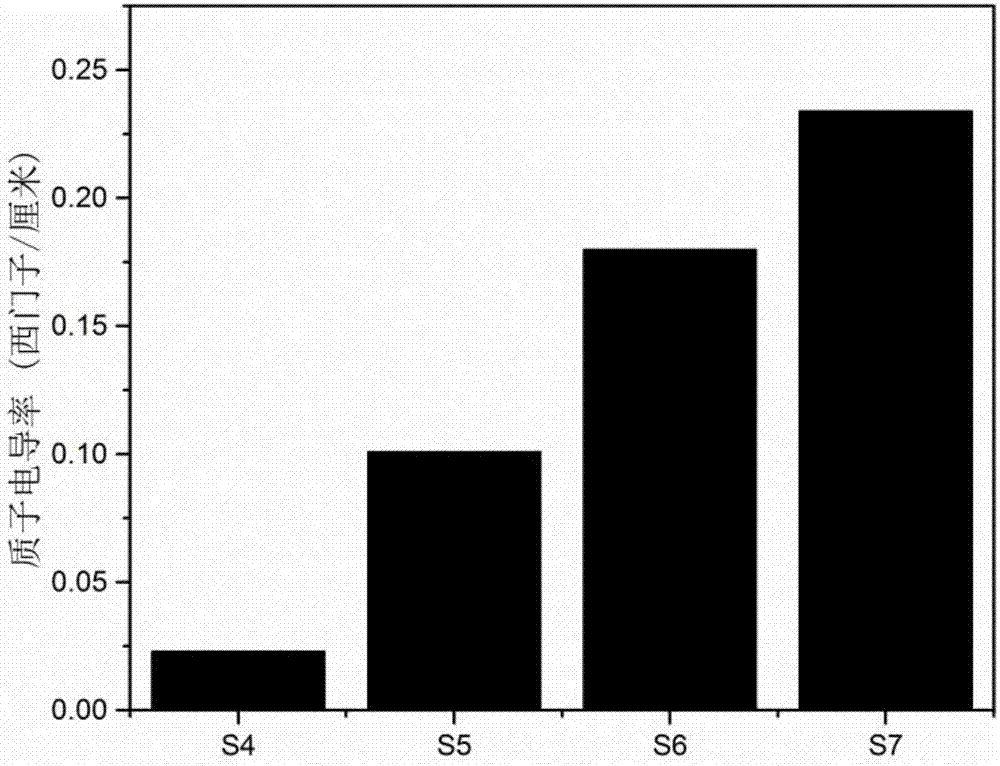

A technology of sulfonated polyaryletherketone and ion-exchange membrane, which is applied in the field of ion-exchange membrane materials, can solve the problems of high price, complex preparation process, and reduced battery capacity, and achieve low cost, simple preparation process, and high proton conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

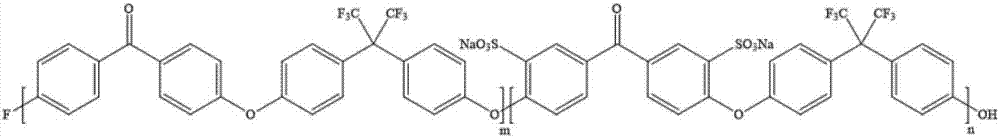

[0037] A kind of preparation method of sulfonated polyaryletherketone ion exchange membrane is provided in this instance, and its concrete steps are:

[0038] 1) Sulfonated 4,4'-difluorobenzophenone: Add 5g of 4,4'-difluorobenzophenone into a 250ml two-necked round bottom flask with a reflux condenser, and then add 20ml of analytically pure Grade concentration is 20% oleum, magnetically stirred and heated to 110°C for reaction; after the reaction is completed, cool to room temperature, slowly pour the product into 100ml of ice-water mixture, stir and add 25g of sodium chloride, until white Suction filter and dry the solid after the solid precipitates; dissolve the dried solid in 20-40ml of deionized water, slowly add sodium hydroxide, adjust the solution to neutral, then add sodium chloride to form a supersaturated solution, and a white solid precipitates , suction filtration, and drying; then the dried solid was heated and dissolved with dimethyl sulfoxide, the insoluble impu...

Embodiment 2

[0043] A kind of preparation method of sulfonated polyaryletherketone ion exchange membrane is provided in this instance, and its concrete steps are:

[0044] 1) Sulfonated 4,4'-difluorobenzophenone: Add 5g of 4,4'-difluorobenzophenone into a 250ml two-necked round bottom flask with a reflux condenser, and then add 20ml of analytically pure Grade concentration is 20% oleum, magnetically stirred and heated to 110°C for reaction; after the reaction is completed, cool to room temperature, slowly pour the product into 100ml of ice-water mixture, stir and add 25g of sodium chloride, until white Suction filter and dry the solid after the solid precipitates; dissolve the dried solid in 20-40ml of deionized water, slowly add sodium hydroxide, adjust the solution to neutral, then add sodium chloride to form a supersaturated solution, and a white solid precipitates , suction filtration, and drying; then the dried solid was heated and dissolved with dimethyl sulfoxide, the insoluble impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com