A kind of preparation method of ultrathin coni alloy nano sheet

A kind of alloy nano and ultra-thin technology, which is applied in nano technology, metal processing equipment, transportation and packaging, etc., can solve the problems of complex preparation methods, and achieve the effect of simple operation, good oxygen evolution electrocatalytic activity, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

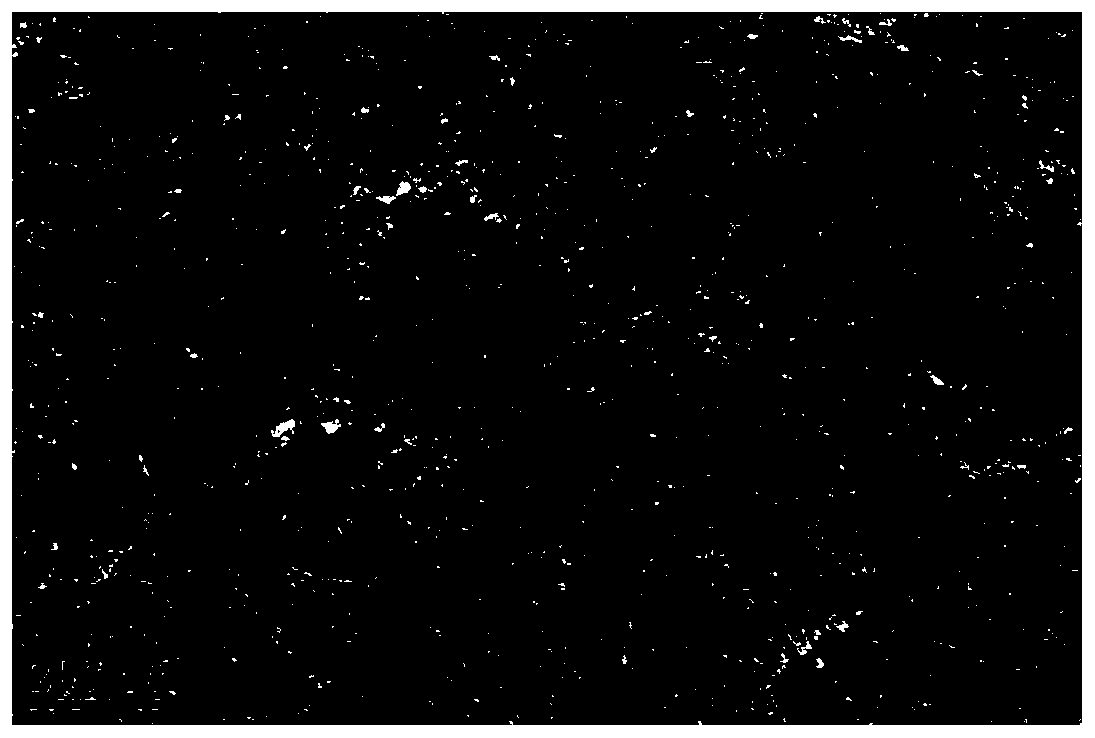

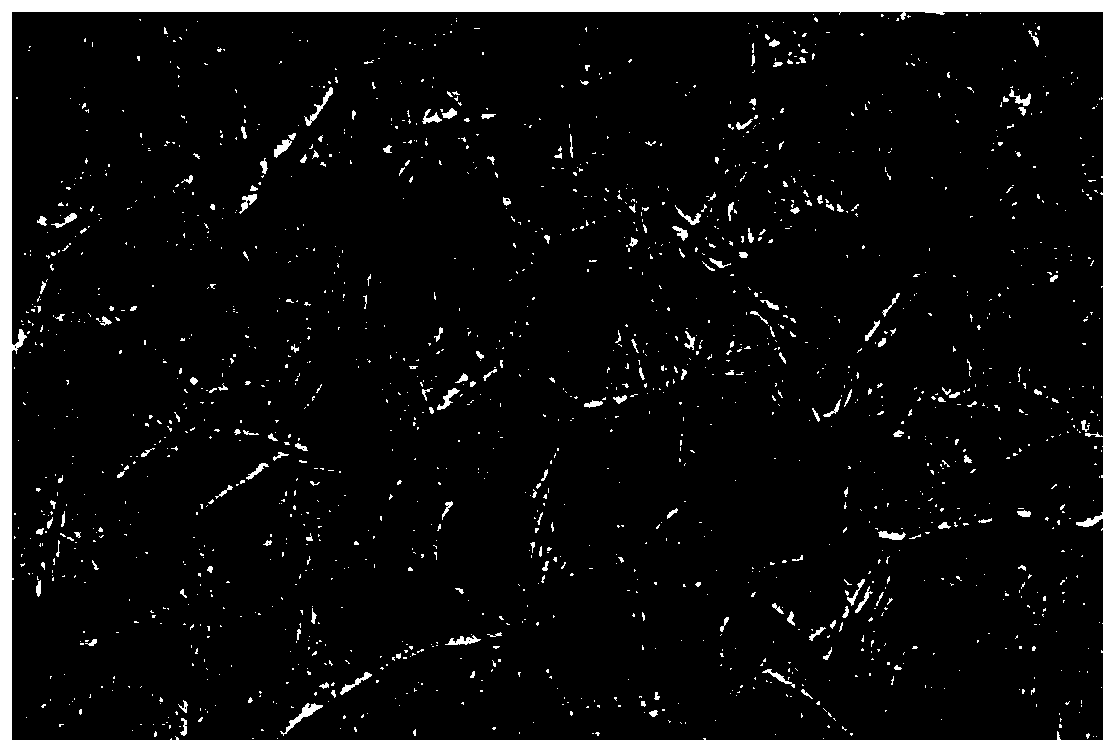

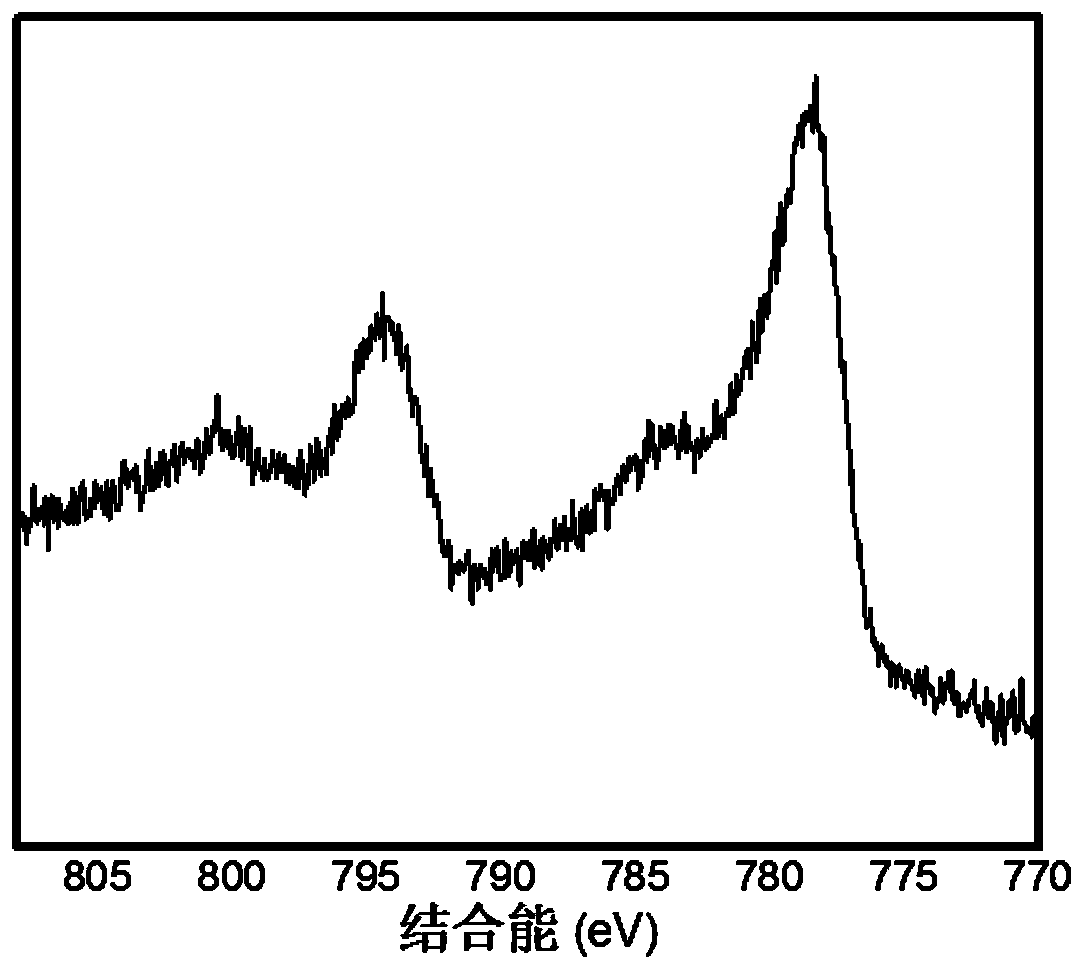

[0022] Add 0.5mL of 2.0mol / L cobalt chloride aqueous solution and 0.5mL of 1.0mol / L potassium tetracyannickelate aqueous solution into a 5mL beaker, mix well, and stand at 40°C for 8 hours to obtain cobalt-nickel cyanide gel, and then Add 50 mL of 3.0 mol / L sodium borohydride aqueous solution under stirring conditions, wherein the molar ratio of potassium tetracyanonickelate to cobalt chloride and sodium borohydride is 1:2:300, reduce the reaction at 70°C for 6 hours, and cool to normal temperature, centrifuged, washed with deionized water, and dried at 60°C in a vacuum oven to obtain ultrathin CoNi alloy nanosheets (see Figure 1~4 ).

Embodiment 2

[0024] Add 0.5mL of 1.5mol / L cobalt chloride aqueous solution and 0.5mL of 1.0mol / L potassium tetracyannickelate aqueous solution into a 5mL beaker, mix well, and stand at 40°C for 8 hours to obtain cobalt-nickel cyanide gel, and then Add 36 mL of 3.5 mol / L sodium borohydride aqueous solution under stirring conditions, wherein the molar ratio of potassium tetracyanonickelate to cobalt chloride and sodium borohydride is 1:1.5:250, reduce the reaction at 70°C for 6 hours, and cool to At room temperature, centrifuged, washed with deionized water, and dried in a vacuum oven at 60°C to obtain ultrathin CoNi alloy nanosheets (see Figure 5 ).

Embodiment 3

[0026] Add 1mL of 2.0mol / L cobalt chloride aqueous solution and 1mL of 1.0mol / L potassium tetracyannickelate aqueous solution into a 5mL beaker, mix well, and let stand at room temperature for 12 hours to obtain cobalt nickel cyanide gel, and then Add 100mL of 3.0mol / L sodium borohydride aqueous solution, wherein the molar ratio of potassium tetracyanonickelate to cobalt chloride and sodium borohydride is 1:2:300, reduce reaction at room temperature for 24 hours, centrifuge, use Washed with ionized water and dried at 60°C in a vacuum oven to obtain ultra-thin CoNi alloy nanosheets (see Figure 6 ).

[0027] The inventor uses the ultra-thin CoNi alloy nanosheets obtained in Example 1 to electrocatalyze oxygen evolution. The specific method is: add 2 mg of ultra-thin CoNi alloy nanosheets to 1 mL of aqueous solution, mix well, take 4 μL of the resulting mixed solution and drop it on the platinum carbon electrode above, to be used for electrochemical test after drying, test resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com