A pretreatment method for growing single crystal orientation zinc oxide

A zinc oxide and pretreatment technology, applied in the semiconductor field, can solve the problems of limited application, poor crystallization quality of zinc oxide film, etc., and achieve good preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

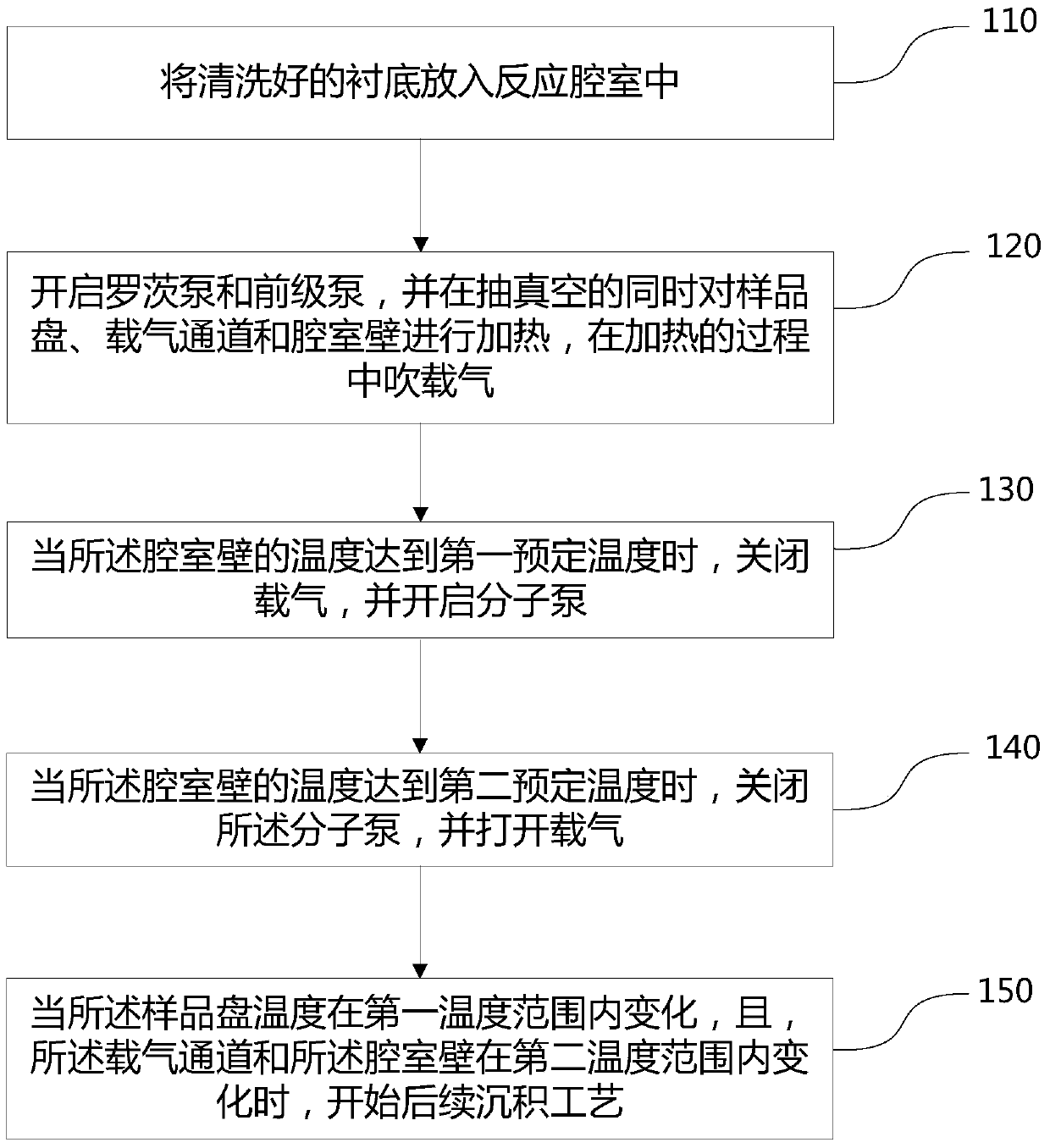

[0030] Such as figure 1 As stated, the embodiment of the present invention provides a pretreatment method for growing zinc oxide with a single crystal orientation, the method comprising:

[0031] Step 110: Put the cleaned substrate into the reaction chamber;

[0032] Specifically, cleaning the substrate adopts a sapphire cleaning step to clean the substrate, and the specific process also includes:

[0033] Step 101: put the substrate in acetone and ultrasonically perform the first predetermined time, and blow it dry after taking it out;

[0034] Step 102: Put the substrate into the isopropanol solution and sonicate for a second predetermined time, and blow it dry after taking it out;

[0035] Step 103: put the substrate in deionized water and ultrasonically for a third predetermined time, and blow it dry after taking it out.

[0036] The first predetermined time, the second predetermined time and the third predetermined time are dynamically adjusted by those skilled in the ...

Embodiment approach

[0054] In order to more clearly illustrate the technical solutions and technical effects of the embodiments of the present invention, the present invention provides specific implementation solutions, the specific contents of which are as follows:

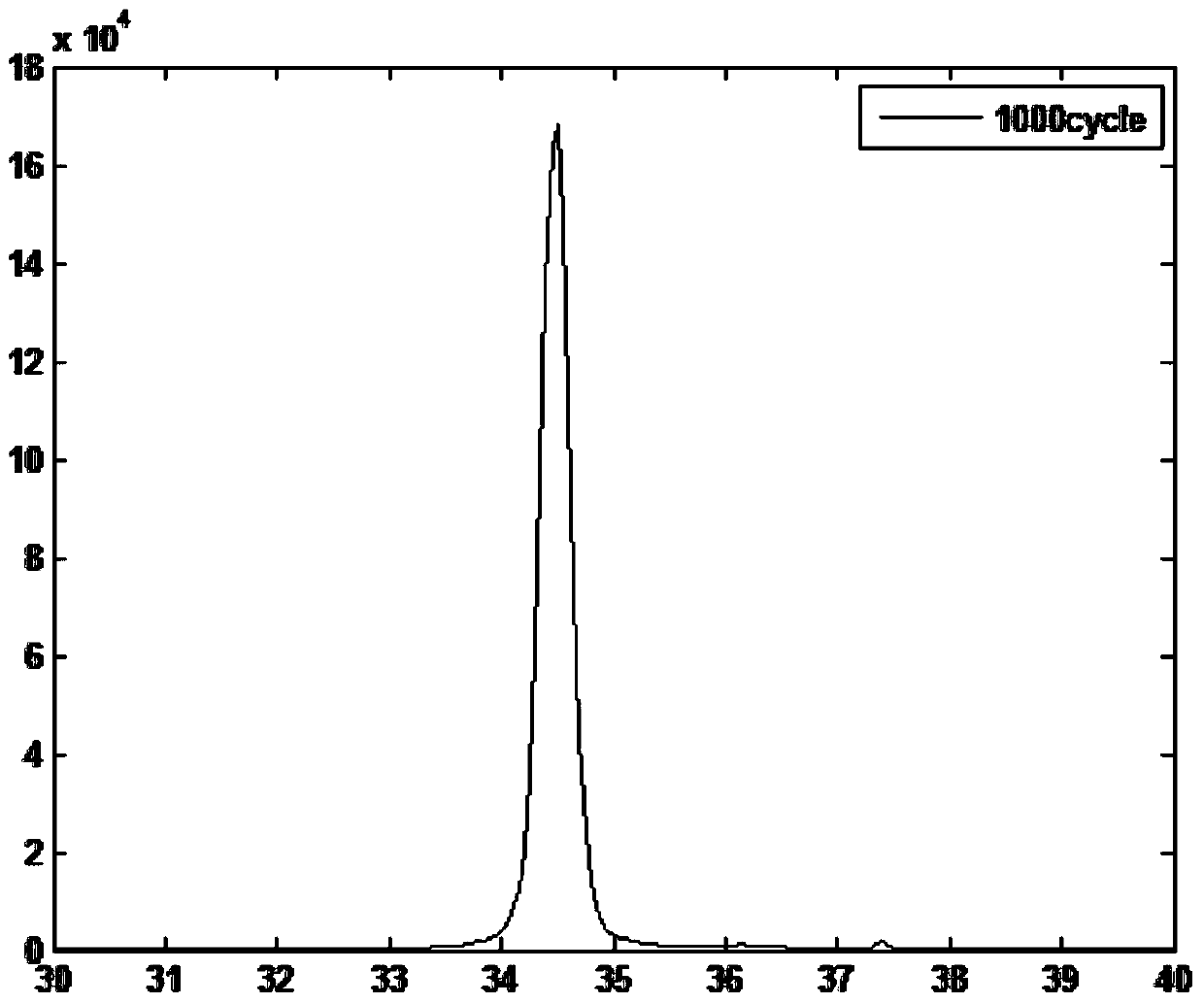

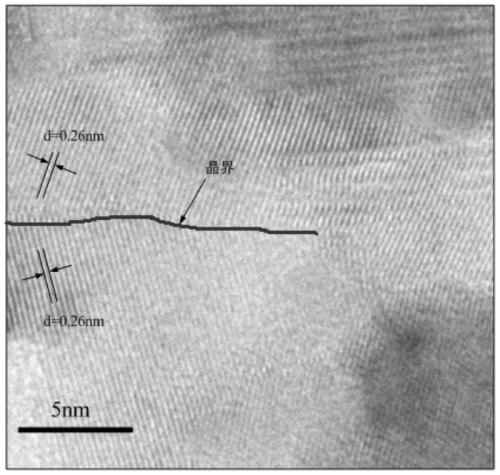

[0055] Put the sapphire substrate with C-axis single orientation into acetone, isopropanol and deionized water and ultrasonically clean it for 5 minutes, take it out and dry it, and put it into the chamber of the atomic layer deposition equipment. Turn on the foreline pump and Roots pump of the equipment, heat the sample tray, chamber wall and carrier gas channel at the same time, and set the heating temperature to 200°C, 100°C and 110°C respectively, and feed high-purity nitrogen as carrier gas during the heating process. When the chamber wall temperature rises to 80°C, the molecular pump is turned on, the carrier gas is turned off, and the molecular pump is stopped until the chamber wall temperature rises to 100°C. After the molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com