Pickled okra and preparation method thereof

A kimchi and purified water technology, applied in the directions of bacteria, yeast-containing food ingredients, food science, etc. used in food preparation, can solve the problems of difficult to achieve industrialized production, difficult to guarantee product quality, unstable quantity and population, etc. The effect of shorter cycle times, improved production efficiency, good taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

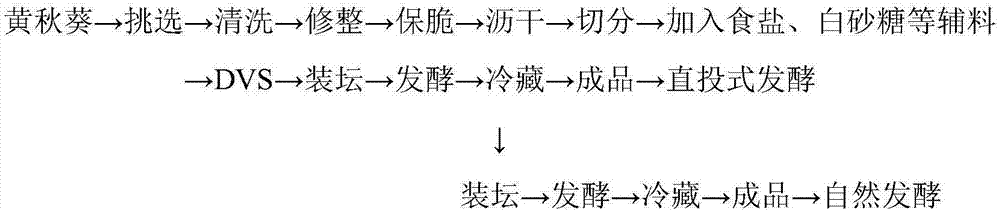

Method used

Image

Examples

Embodiment 1

[0036] Preparation: 100 parts of okra are washed with water, and then trimmed to obtain undamaged okra. Add 0.15% L-calcium lactate to keep it crisp, and then put the okra in 90°C water for 3 minutes to blanch. Then take out the okra and cut it into pieces to obtain chunks of okra with almost the same size. Add auxiliary materials, 150 parts of purified water, 10 parts of table salt, 10 parts of white sugar, 1 part of calcium chloride, 10 parts of cooking wine, 0.2 parts of star anise, 0.2 parts of fennel, 1 part of pepper, and 0.01 part of vitamin C. After adding 10% of Lactobacillus plantarum and 1% of Torulopsis globosa, put the okra into an altar for fermentation, place it at 25° C. for 4 days, and prepare the okra kimchi.

Embodiment 2

[0047] 100 parts of okra are cleaned with water, and then trimmed to obtain undamaged okra. Add 0.5% L-calcium lactate to keep it crisp, and then put the okra in 90°C water to blanch for 3 minutes. Then take out the okra and cut it into pieces to obtain chunks of okra with almost the same size. Add auxiliary materials, 80 parts of purified water, 1 part of table salt, 1 part of white sugar, 0.1 part of calcium chloride, 1 part of cooking wine, 0.02 part of star anise, 0.02 part of fennel, 0.1 part of pepper, and 0.05 part of vitamin C. After adding 1% of Lactobacillus plantarum and 0.1% of Zygosaccharomyces rouckeri, the okra is placed in an altar for fermentation, placed at 25° C. for 5 days, and the okra kimchi is obtained.

Embodiment 3

[0049] 100 parts of okra are cleaned with water, and then trimmed to obtain undamaged okra. Add 0.1% L-calcium lactate to keep it crisp, and then put the okra in 90°C water to blanch for 3 minutes. Then take out the okra and cut it into pieces to obtain chunks of okra with almost the same size. Add auxiliary materials, 120 parts of purified water, 6 parts of table salt, 7 parts of white sugar, 0.3 parts of calcium chloride, 7 parts of cooking wine, 0.18 parts of star anise, 0.14 parts of fennel, 0.4 parts of pepper, and 0.03 parts of vitamin C. After adding 8% of Lactobacillus plantarum, 0.9% of Candida variabilis and Hansenula spp., the okra was fermented in an altar, and fermented at 25° C. for 4 days to obtain okra kimchi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com