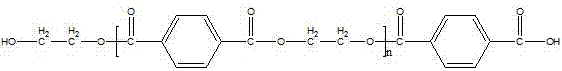

Method for controlled degradation and recovery of polyethylene terephthalate material

A technology of polyethylene terephthalate and ethylene phthalate, which is applied in the field of polymer material recycling and resource utilization, can solve the problem of high degradation cost, harsh reaction conditions for PET material degradation, and difficult degradation products. Separation and other problems, to achieve the effect of mild reaction conditions and low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

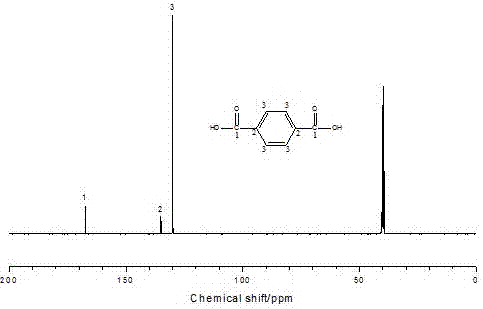

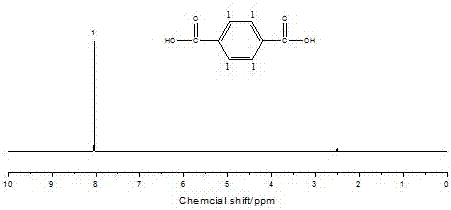

Embodiment 1

[0022] Preparation of ZnCl with a mass fraction of 70% 2 and H 2 Degradation solution composed of O, in which 70g ZnCl 2 , 30g H 2 O. According to the mass ratio of 1:20, 5g of polyethylene terephthalate material (PET bottle) was immersed in the degradation solution and sealed in the reaction kettle. The degradation reaction temperature was 200°C and the reaction time was 8h. After the degradation reaction is completed, cool to room temperature. Then add the diluent ethyl acetate, the mass ratio of ethyl acetate and the degradation product mixture is 2:1, filter and separate to obtain the solid product terephthalic acid, and the liquid product is distilled under reduced pressure to obtain ethylene glycol.

Embodiment 2

[0024] Preparation of ZnCl with a mass fraction of 80% 2 and H 2 Degradation solution composed of O, in which 80g ZnCl 2 , 20g H 2 O. Immerse 4g of polyethylene terephthalate material (PET bottle) in the degradation solution at a mass ratio of 1:25, and seal the mixture in a reaction kettle. The degradation reaction temperature is 180°C and the reaction time is 12 hours. After the degradation reaction is completed, cool to room temperature. Then add diluent diethyl ether, the mass ratio of diethyl ether and degradation product mixture is 5:1, filter and separate to obtain the solid product terephthalic acid, and the liquid product is distilled under reduced pressure to obtain ethylene glycol.

Embodiment 3

[0026] Preparation of FeCl with a mass fraction of 5% 3 and acetic acid degradation solution, in which 5g FeCl 3 , 95g acetic acid. Immerse 10g of polyethylene terephthalate material (PET fiber) in the degradation solution at a mass ratio of 1:10, and seal the mixture in a reaction kettle. The degradation reaction temperature is 260°C and the reaction time is 1h. After the degradation reaction is completed, cool to room temperature. Then add diluent chloroform, the mass ratio of chloroform and degradation product mixture is 3:1, filter and separate to obtain solid product terephthalic acid, and liquid product is obtained ethylene glycol diacetate by vacuum distillation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com