A Semi-Superjunction MOSFET with Auxiliary Buried Oxide

A buried oxide and semi-superjunction technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of increasing the threshold voltage of MOSFET devices, preventing the parasitic BJT tube from being turned on completely, and reducing the parasitic BJT base area Resistance and other issues, to improve the UIS capability, increase the contribution, and avoid the effect of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

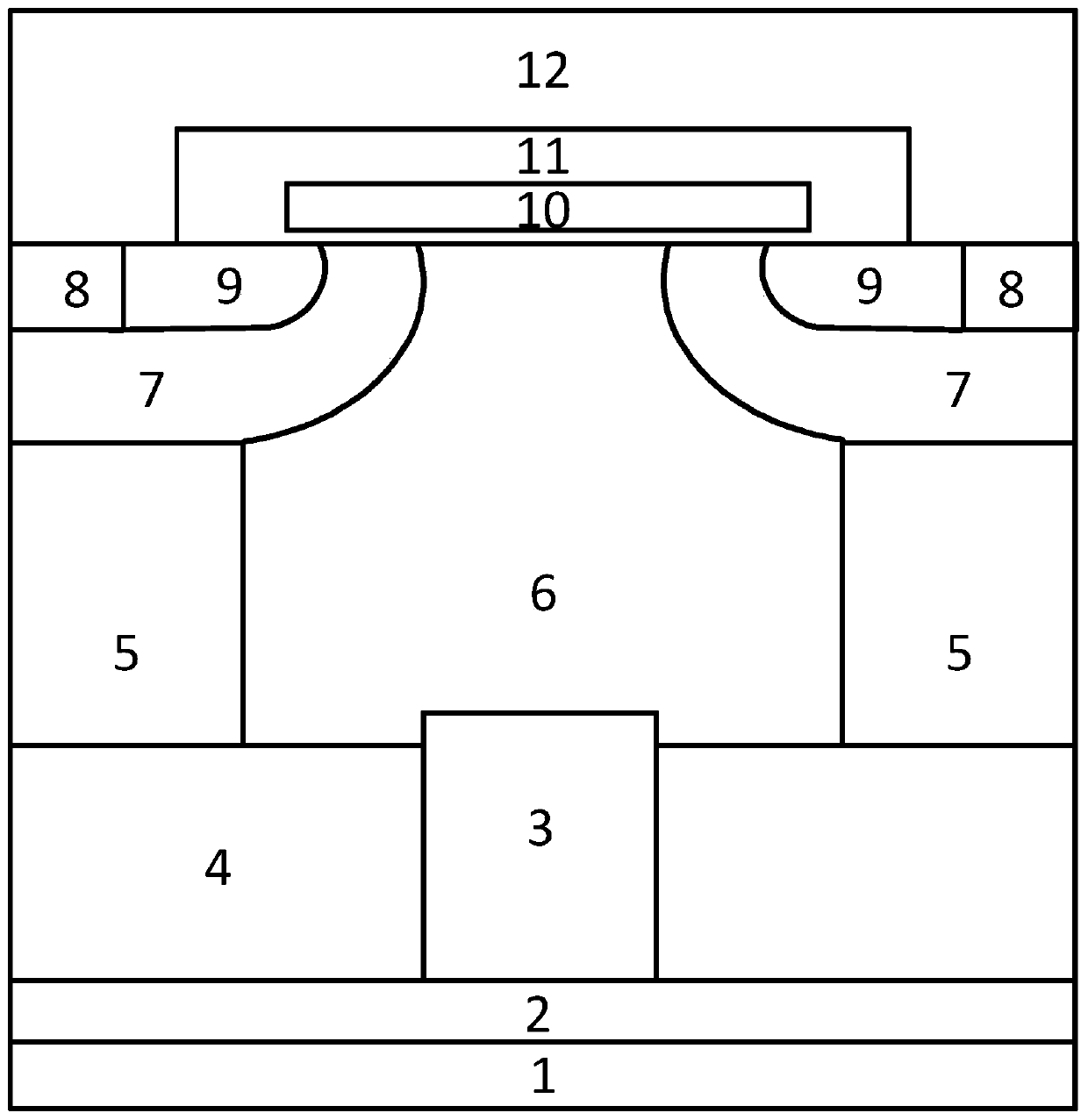

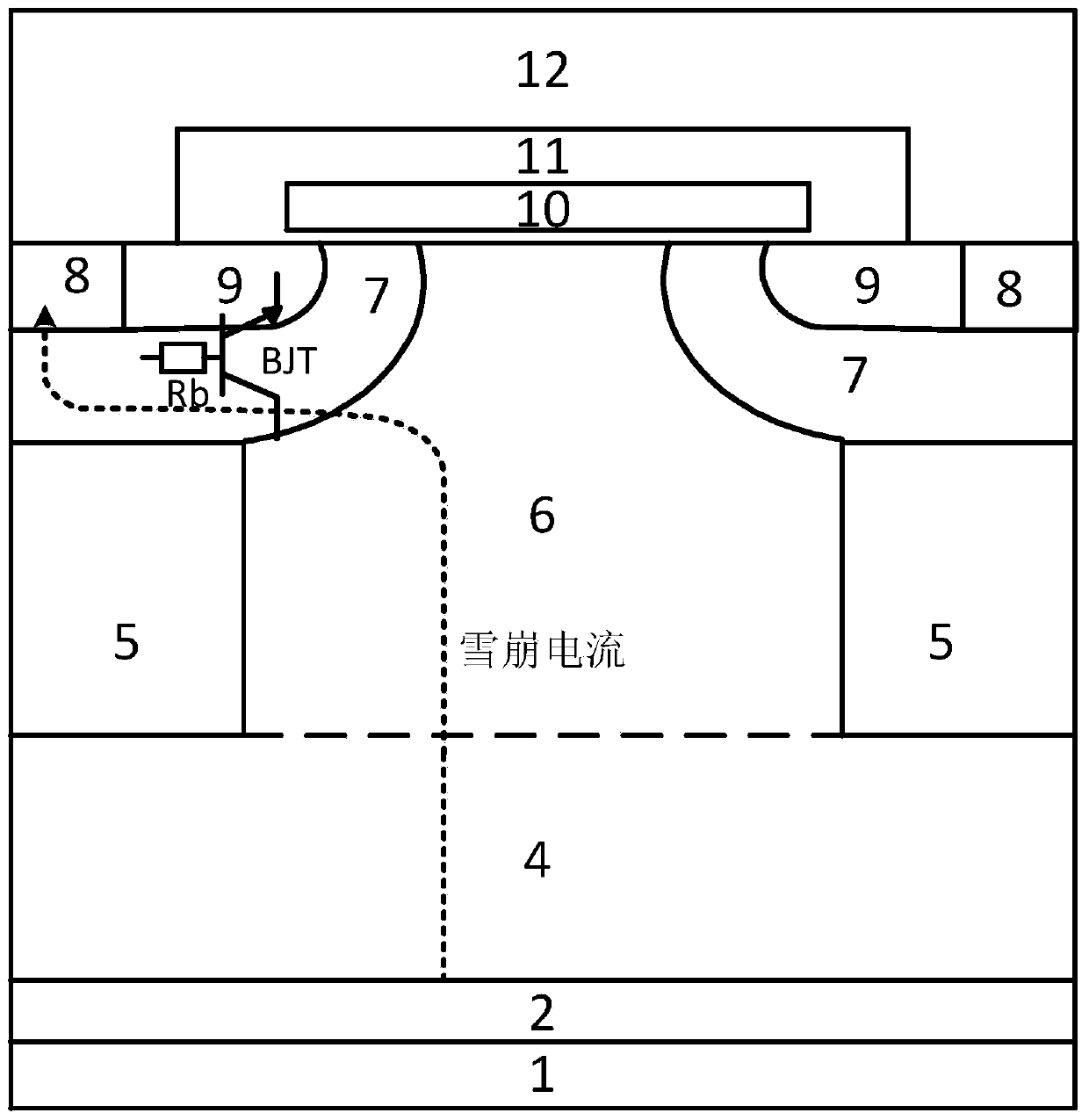

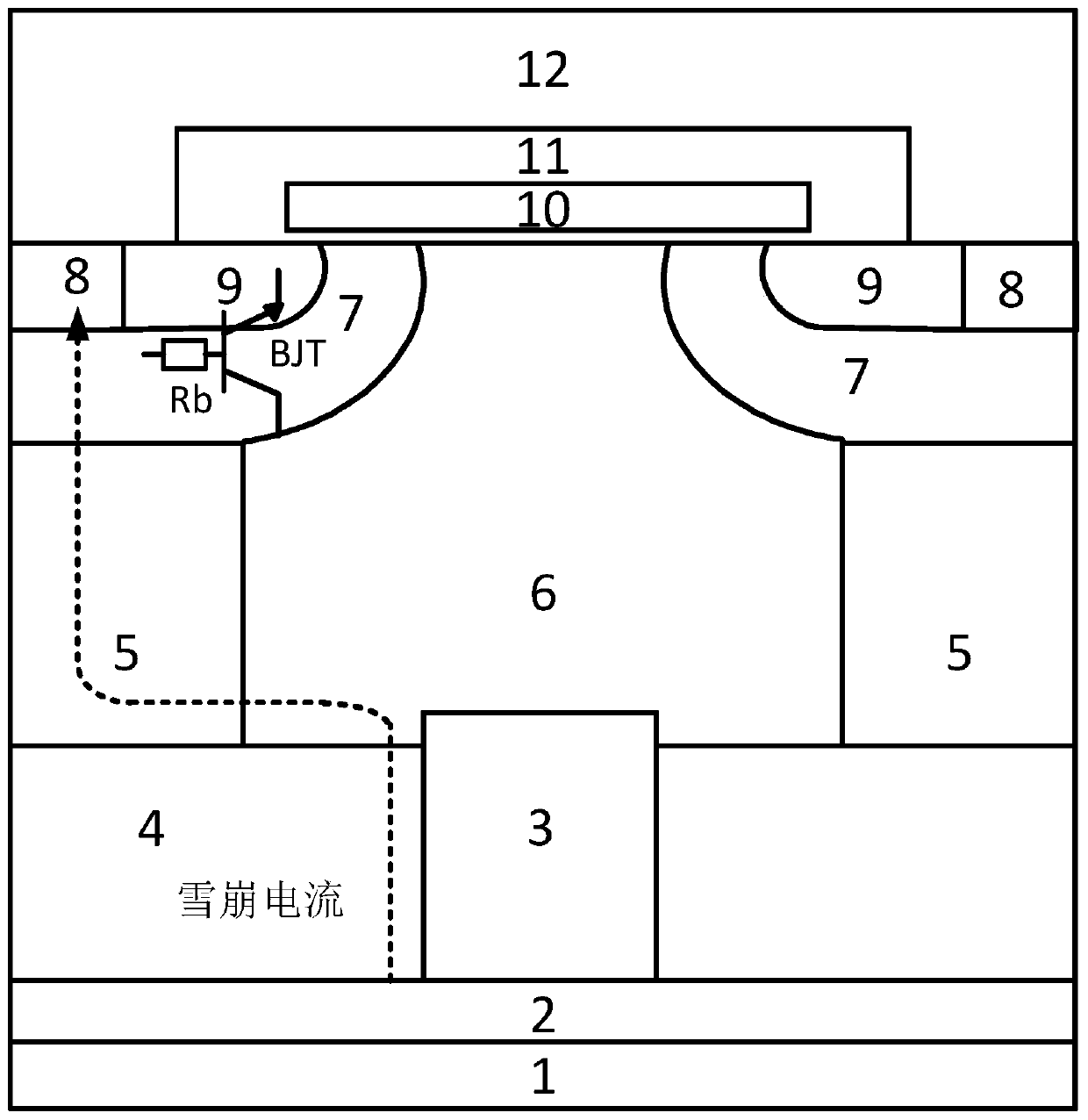

[0021] A semi-superjunction MOSFET with assisted buried oxide, such as figure 1As shown, it includes metallized drain electrode 1, first conductivity type semiconductor highly doped substrate 2, first conductivity type semiconductor doped bottom auxiliary layer 4, second conductivity type semiconductor doped column region 5, first conductivity type semiconductor Doped column region 6, polysilicon gate electrode 10, gate dielectric layer 11 and metallized source electrode 12; the first conductive type semiconductor doped substrate 2 is arranged on the upper end surface of the metallized drain electrode 1; the first conductive Type semiconductor doped bottom auxiliary layer 4 is arranged on the upper end surface of the first conductivity type semiconductor doped substrate 2; the second conductivity type semiconductor doped column region 5 and the first conductivity type semiconductor doped column region 6 are arranged on the first conductivity type semiconductor doped column reg...

Embodiment 2

[0030] Such as Figure 7 As shown, the structure of this example is based on Example 1, and the two ends of the metallized source electrode 12 described in Example 1 are extended downwards into the semiconductor body region 7 of the second conductivity type to form a trench structure; The second conductive type semiconductor doped contact region 8 is located at the bottom of the trench with the metallized source electrode 12 at both ends. The structure can further optimize the avalanche current path and improve the UIS capability of the device.

[0031] In the above embodiments, silicon carbide, gallium arsenide, silicon germanium and other semiconductor materials can also be used instead of silicon when making devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com