Formaldehyde-contaminated sludge treatment agent and preparation method thereof

A sludge treatment and formaldehyde technology, which is applied in sludge treatment, water/sludge/sewage treatment, sludge detoxification, etc., can solve the problems of increasing treatment costs and large dosage of drugs, and achieves significant treatment effects and good economy benefits, effects of broad social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

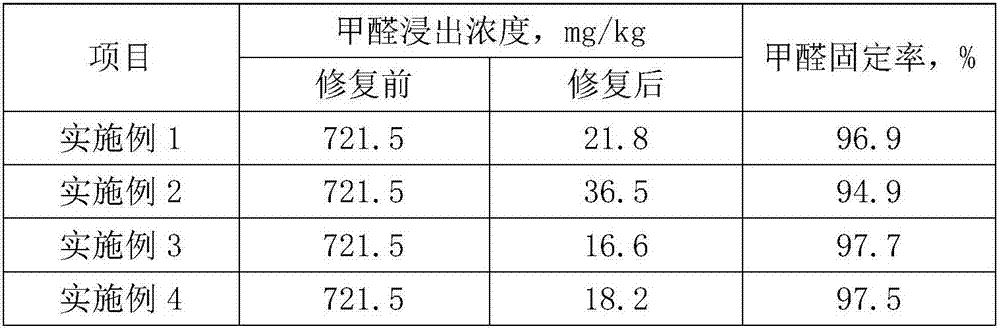

Examples

Embodiment 1

[0020] A formaldehyde-contaminated sludge treatment agent, comprising the following parts by weight of raw materials: 15 parts by weight of alumina, 8 parts of dibutyl maleate, 4 parts of macroleaf rubidin, 5 parts of sodium alkylbenzene sulfonate, bamboo vinegar powder 10 parts, 3 parts of octanoyl salicylic acid, 4 parts of phosphogypsum, 5 parts of betel nut powder, 4 parts of disodium edetate, 1 part of tea tree oil, 2 parts of cocamidopropyl betaine, 0.1 part of emulsifier , 2 parts of shell powder, 2 parts of beef bone powder, 0.5 parts of tea polyphenols, 3 parts of toon leaf powder, 1 part of zeolite powder, 1 part of nano silver.

[0021] A preparation method of a formaldehyde-contaminated sludge treatment agent, comprising the following steps: (1) mixing alumina, zeolite powder, nano silver, toon leaf powder, betel nut powder and bamboo vinegar powder, ball milling and stirring at 110°C for 5 hours, and stirring Speed 250r / min to obtain mixture A; (2) Then add shell p...

Embodiment 2

[0023] A formaldehyde-contaminated sludge treatment agent, comprising the following parts by weight of raw materials: 30 parts by weight of alumina, 14 parts by dibutyl maleate, 8 parts by macroleaf rubidin, 10 parts by sodium alkylbenzene sulfonate, and bamboo vinegar powder 15 parts, octanoyl salicylic acid 5 parts, phosphogypsum 11 parts, betel nut powder 12 parts, disodium edetate 8 parts, tea tree oil 3 parts, cocamidopropyl betaine 8 parts, emulsifier 0.1 part , 4 parts of shell powder, 5 parts of beef bone powder, 0.1 part of tea polyphenols, 7 parts of toon leaf powder, 4 parts of zeolite powder, 3 parts of nano silver.

[0024] A preparation method of a formaldehyde polluted sludge treatment agent, including the following steps:

[0025] (1) Mix alumina, zeolite powder, nano-silver, toon leaf powder, betel nut powder and bamboo vinegar powder, and stir at 150℃ for 8 hours with a stirring speed of 305r / min to obtain mixture A; (2) then add to mixture A Add shell powder, be...

Embodiment 3

[0027] A formaldehyde-contaminated sludge treatment agent, comprising the following parts by weight of raw materials: 19 parts by weight of aluminum oxide, 10 parts of dibutyl maleate, 6 parts of macroleaf rubidin, 7 parts of sodium alkylbenzene sulfonate, bamboo vinegar powder 12 parts, 4 parts of octanoyl salicylic acid, 7 parts of phosphogypsum, 9 parts of betel nut powder, 6 parts of disodium edetate, 2 parts of tea tree oil, 5 parts of cocamidopropyl betaine, 0.5 parts of emulsifier , 3 parts of shell powder, 4 parts of beef bone powder, 0.8 parts of tea polyphenols, 5 parts of toon leaf powder, 2 parts of zeolite powder, 1.5 parts of nano silver.

[0028] A preparation method of a formaldehyde-contaminated sludge treatment agent, comprising the following steps: (1) mixing alumina, zeolite powder, nano silver, toon leaf powder, betel nut powder and bamboo vinegar powder, ball milling and stirring at 135°C for 6.5 hours, The stirring speed was 285 r / min, and the mixture A was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com