Method for purifying and directionally immobilizing histidine tag protein and application

A technique of histidine tagging and directional immobilization, which is applied in the preparation of purified and directional immobilized histidine tagged protein materials, and in the field of surface modification of biological materials, which can solve the problems of easy dissociation of immobilized proteins, high product prices, and complicated preparation processes and other problems, to achieve the effect of easy reuse, convenient purification and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Histidine-tagged protein purification and immobilization experiments

[0041] 1) With deionized water as solvent, prepare 6.4mg / ml tannic acid solution and 1.6mg / ml FeCl respectively 3 ·6H 2 O solution, 1 mg / ml polysulfobetaine solution, 2.5 mg / ml CoCl 2 solution;

[0042] 2) Using silicon wafers as the carrier material, place 1×1cm silicon wafers in a 5ml centrifuge tube, add 1ml tannic acid solution and 1ml FeCl in sequence 3 Solution, oscillate evenly, place at room temperature for 3mins, take out the silicon wafer with tweezers, and wash it three times with deionized water;

[0043] 3) Put the silicon chip in 2) back into the 5ml centrifuge tube, and add 1ml FeCl in turn 3 solution and 1ml tannic acid solution, shake evenly, place at room temperature for 3mins, take out the silicon wafer, and wash it three times with deionized water;

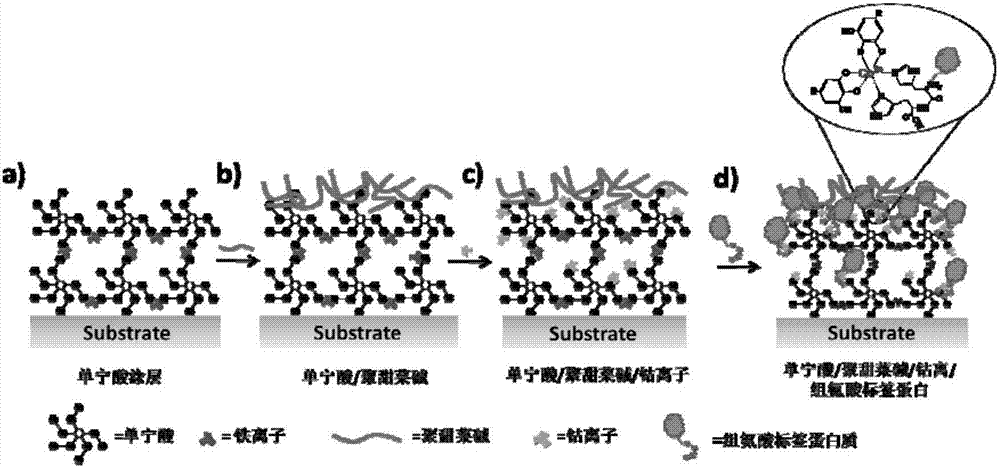

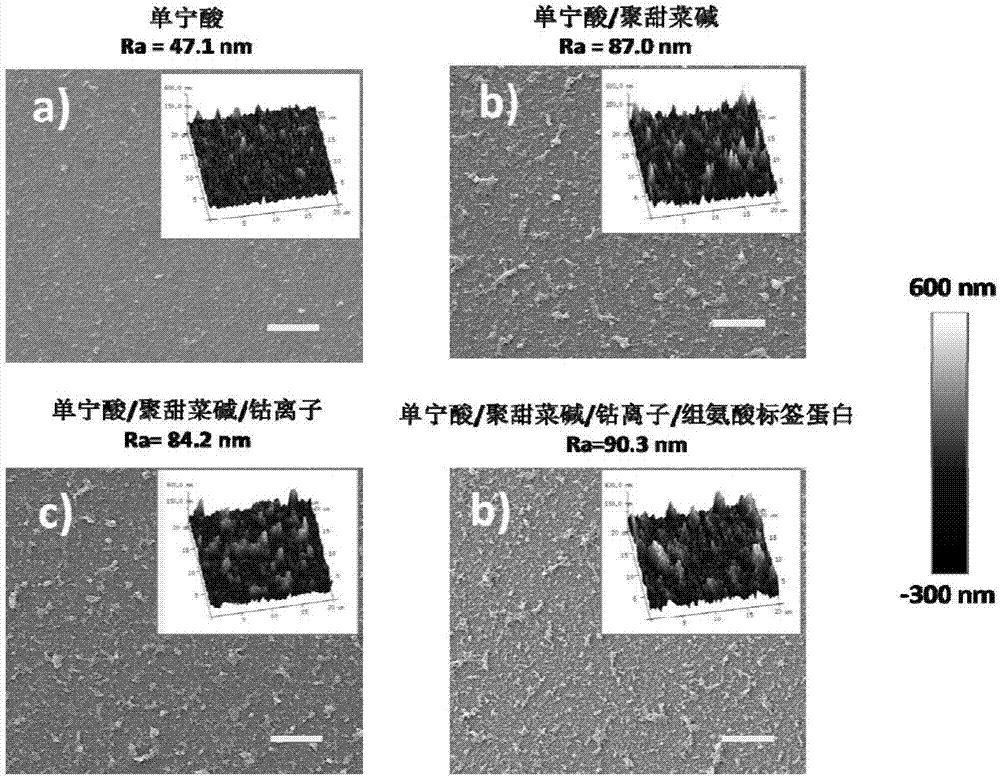

[0044] 4) Repeat step 3) 5 times to obtain multilayer modified TA / Fe 3+ material surface ( figure 1 a)

[0045] 5)...

Embodiment 2

[0049] Example 2 Histidine-tagged protein purification experiment

[0050] 1) With deionized water as solvent, prepare 6.4mg / ml tannic acid solution and 1.6mg / ml FeCl respectively 3 ·6H 2 O solution, 1 mg / ml polysulfobetaine solution, 2.5 mg / ml CoCl 2 solution;

[0051] 2) Using magnetic microspheres with a diameter of 300nm as the carrier material, put 0.1g of magnetic microspheres into a 5ml centrifuge tube, add 2ml of tannic acid solution and 2ml of FeCl in turn 3 Solution, shake and disperse evenly, stir at room temperature for 5mins, magnetically separate, wash with deionized water three times;

[0052] 3) Put the magnetic microspheres in 2) back into the 5ml centrifuge tube, and add 2ml FeCl in turn 3 solution and 2ml tannic acid solution, shake and disperse evenly, stir at room temperature for 5mins, take out by magnetic separation, and wash with deionized water three times;

[0053] 4) Repeat step 3) 3 times;

[0054] 5) Place the silicon chip in 4) in a 5ml cent...

Embodiment 3 2

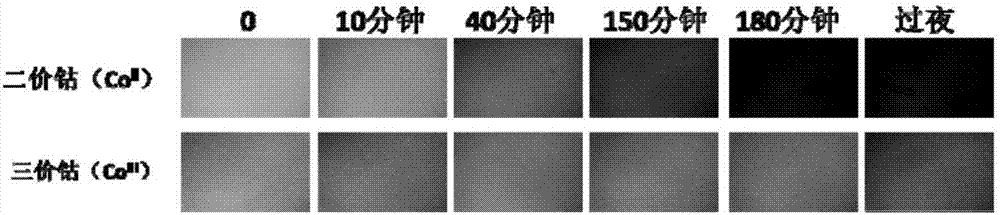

[0059] Example 3 The experiment of the influence on the stability of immobilized protein after divalent cobalt is oxidized to trivalent

[0060] 1) With deionized water as solvent, prepare 6.4mg / ml tannic acid solution and 1.6mg / ml FeCl respectively 3 ·6H 2 O solution, 1 mg / ml polysulfobetaine solution, 2.5 mg / ml CoCl 2 solution;

[0061] 2) Using silicon wafers as the carrier material, place 1×1cm silicon wafers in a 5ml centrifuge tube, add 1ml tannic acid solution and 1ml FeCl in sequence 3 Solution, oscillate evenly, place at room temperature for 3mins, take out the silicon wafer with tweezers, and wash it three times with deionized water;

[0062] 3) Put the silicon chip in 2) back into the 5ml centrifuge tube, and add 1ml FeCl in turn 3 solution and 1ml tannic acid solution, shake evenly, place at room temperature for 3mins, take out the silicon wafer, and wash it three times with deionized water;

[0063] 4) Repeat step 3) 5 times to obtain multilayer modified TA / F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com