Preparation method of high-strength and heat-resistant liquid crystal polymer spunbond nonwoven fabric

A technology of liquid crystal polymer and spunbond non-woven fabrics, applied in the direction of melt spinning, non-woven fabrics, rayon manufacturing, etc., can solve the problem that ordinary spunbond non-woven fabrics cannot withstand high strength and high heat, and achieve excellent thermal stability. Properties and dimensional stability, low melt viscosity, low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a high-strength heat-resistant liquid crystal polymer spunbonded non-woven fabric in this embodiment:

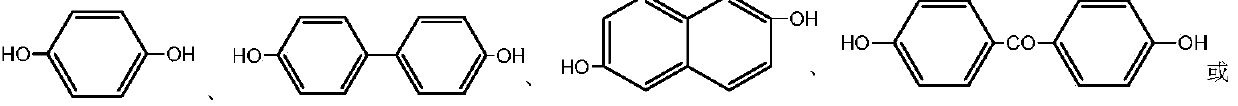

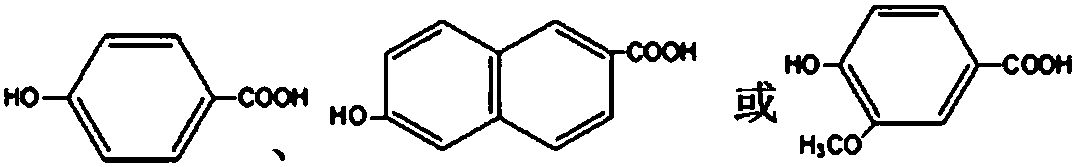

[0029] The liquid crystal polymer structure is The auxiliary agent is antioxidant 1010, and the auxiliary agent consumption is 0.05%.

[0030] 1. The preparation process of liquid crystal polymer is:

[0031] React the monomer 6-hydroxyl-2-naphthoic acid and p-hydroxybenzoic acid with excess acetic anhydride respectively, and obtain 6-acetoxy-2-naphthoic acid (ANA) and p-acetoxy Benzoic acid (ABA). ABA and ANA were added into the reactor at a molar ratio of 73:27, and sodium acetate was used as a catalyst in an amount of 0.1% of the total mass of the monomers. After exhausting the air in the reaction system with nitrogen, raise the temperature to 250°C and keep it for 2h, then raise the temperature to 280°C, keep it for 2h, then raise the temperature to 320°C, stop filling the nitrogen after 30min, apply a vacuum atmosphere to the system, t...

Embodiment 2

[0035] A preparation method of a high-strength heat-resistant liquid crystal polymer spunbonded non-woven fabric in this embodiment:

[0036] The liquid crystal polymer structure is The auxiliary agent is antioxidant 1010, and the consumption amount of the auxiliary agent is 0.01%.

[0037] 1. The preparation process of liquid crystal polymer is:

[0038] React the monomer p-hydroxybenzoic acid and biphenol with excess acetic anhydride respectively, and obtain 4-acetoxy-parabenzoic acid (ABA) and 4,4'-diacetoxy after washing, purification and drying. biphenyl (ABP). ABA, ABP and 2,6-naphthalene dicarboxylic acid are added into the reactor at a molar ratio of 50:25:25, and sodium acetate is used as a catalyst in an amount of 0.1% of the total mass of monomers. After removing the air in the reaction system with nitrogen, raise the temperature to 280°C and keep it for 3h, then raise the temperature to 300°C, keep it for 2h, then raise the temperature to 340°C, stop filling th...

Embodiment 3

[0042] A preparation method of a high-strength heat-resistant liquid crystal polymer spunbonded non-woven fabric in this embodiment:

[0043] The liquid crystal polymer structure is The auxiliary agent is antioxidant 1076, and the consumption amount of the auxiliary agent is 0.1%.

[0044]1. The preparation process of liquid crystal polymers is as follows: the monomer 6-hydroxy-2-naphthoic acid, 2,6-naphthalene dicarboxylic acid and hydroquinone are added to the reactor with a molar ratio of 60:20:20 and excess acetic anhydride Among them, methylimidazole is used as a catalyst, and the dosage is 0.3% of the total mass of monomers. After exhausting the air in the reaction system with nitrogen, raise the temperature to 130°C and keep it for 3h for acetylation reaction, then raise the temperature to 250°C, keep it for 3h, then raise the temperature to 300°C, continue the reaction for 2h, finally raise the temperature to 310°C, stop charging after 30min Nitrogen, apply a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com