Method for pretreating and converting biomass into 5-hydroxymethyl furfural

A technology of hydroxymethylfurfural and biomass, which is applied in the field of 5-hydroxymethylfurfural, can solve the problems of high energy consumption, low conversion rate, poor penetration and other problems, and achieve good chemical stability and catalytic effect Visible, strong solvency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Ultrasound-ionic liquid pretreatment of biomass: bagasse was used as biomass raw material, [Bmim]Cl ionic liquid was used as solvent, and the biomass sieved with 100 meshes was sieved according to the solid-liquid ratio (g / ml) of 1:20. Mix the substance with the ionic liquid, stir it magnetically at 80°C, and apply ultrasonic waves at a frequency of 20kHz for 30min to completely dissolve the biomass in the ionic liquid;

[0055] (2) Acquisition of regenerative organisms: After the reaction is over, distilled water is added to the reaction solution at a ratio of 3 to 5 times that of the ionic liquid, the ionic liquid is dissolved in distilled water and a precipitate is precipitated, and the precipitate is filtered out and washed 3 to 5 times with distilled water Dry in an oven at 80°C to obtain regenerated biomass;

[0056] (3) Recovery of ionic liquid: After the biomass is precipitated, the obtained solution is a mixed liquid of water and ionic liquid, and the water...

Embodiment 2

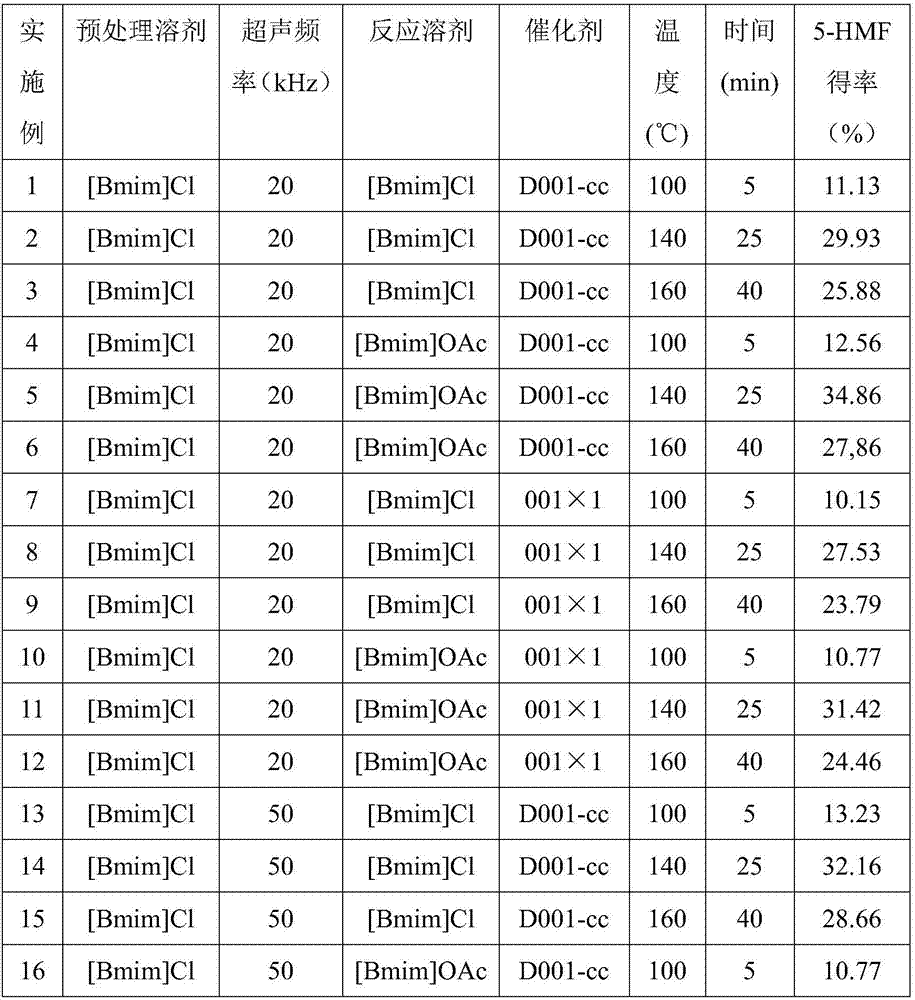

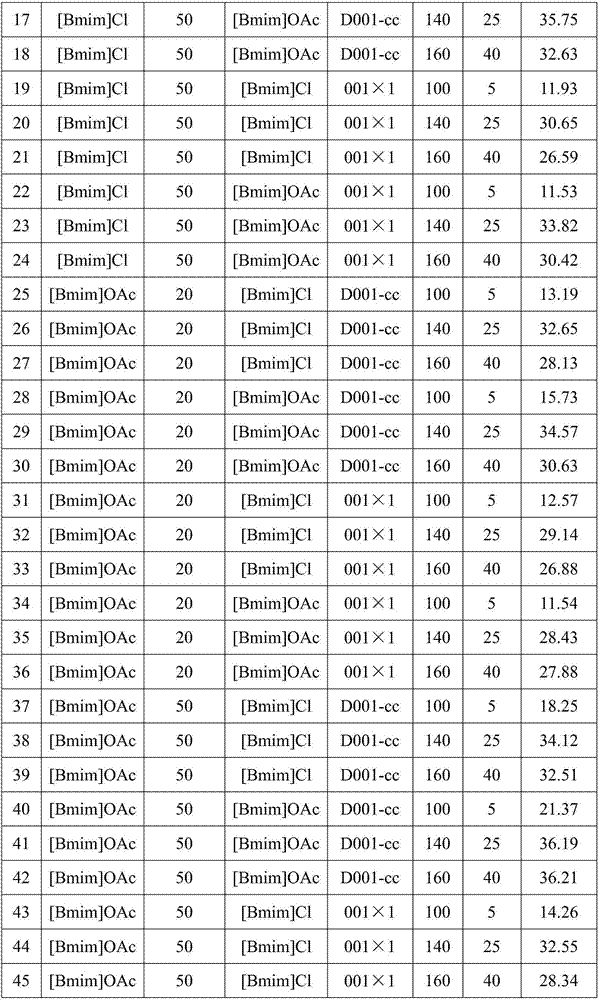

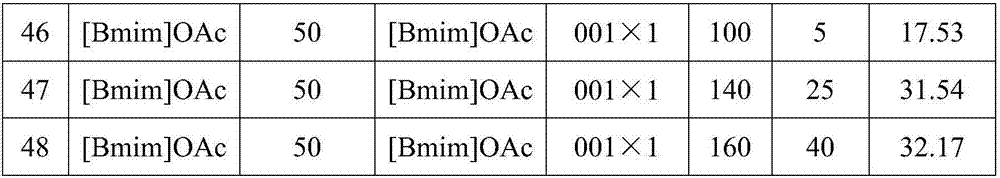

[0061] Other steps are all consistent with embodiment 1, but the pretreatment solvent used, ultrasonic frequency, reaction solvent, catalyzer, the temperature and the time of reaction are different, and concrete test parameter and result are listed in table 1

[0062]

[0063]

[0064]

Embodiment 49

[0066] (1) Ultrasonic-ionic liquid pretreatment of biomass: bagasse was used as biomass raw material, [Bmim]OAc ionic liquid was used as solvent, and the biomass sieved with 100 meshes was sieved according to the solid-liquid ratio (g / ml) of 1:20. Mix the substance with the ionic liquid, stir it magnetically at 80°C, and apply ultrasonic waves with a frequency of 40kHz for 30min to completely dissolve the biomass in the ionic liquid;

[0067] (2) Acquisition of regenerative organisms: After the reaction is over, distilled water is added to the reaction solution at a ratio of 3 to 5 times that of the ionic liquid, the ionic liquid is dissolved in distilled water and a precipitate is precipitated, and the precipitate is filtered out and washed 3 to 5 times with distilled water Dry in an oven at 80°C to obtain regenerated biomass;

[0068] (3) Recovery of ionic liquid: After the biomass is precipitated, the obtained solution is a mixed liquid of water and ionic liquid, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com