Amphiphilic compound modified starch derivative and preparation method thereof

A technology of starch derivatives and compound modification, applied in the field of compound modified starch, can solve the problems such as the inability to meet the rapid development of the industry, poor swelling of esterified starch, poor film toughness, etc., achieve good solubility and emulsification, and significantly increase Viscosity and property improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

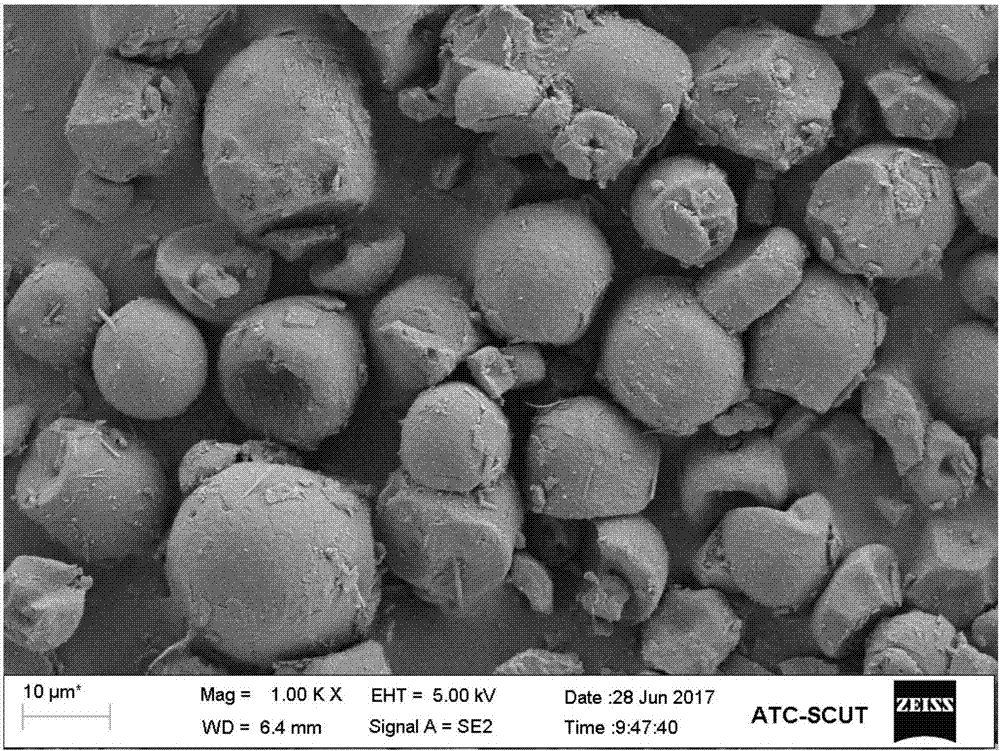

Image

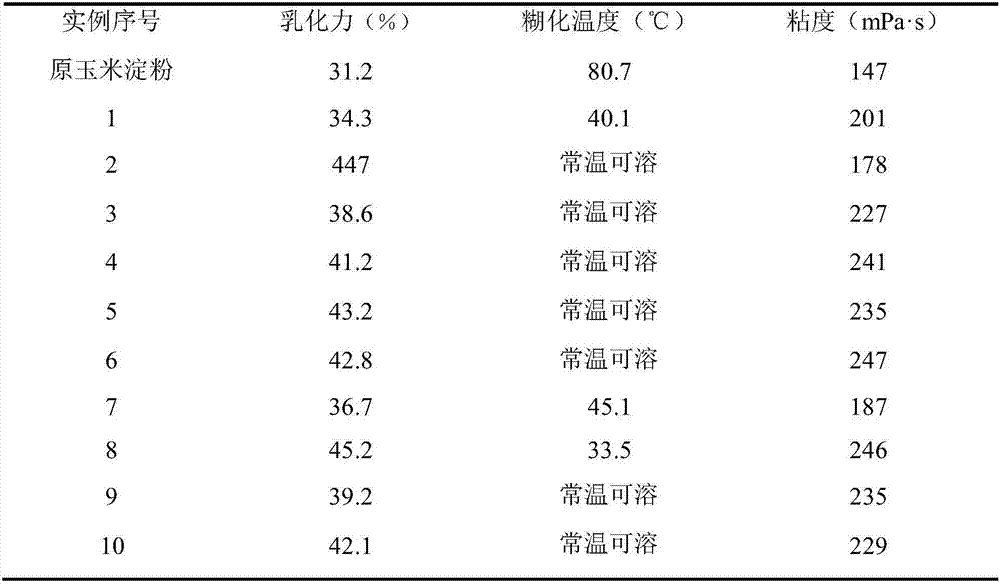

Examples

Embodiment 1

[0038] (1) pretreatment: adding 95% aqueous ethanol solution to potato starch to prepare starch milk with a concentration of 15% wt;

[0039] (2) Hydroxypropylation treatment: in the starch after step (1) pretreatment, add the sodium hydroxide (being sodium hydroxide aqueous solution, mass concentration is 40%) of starch quality 1%wt under stirring, and starch Propylene oxide with a mass of 20% wt, seal the reactor, let it stand at room temperature for 30 minutes, heat it to 50°C, stir and react for 6 hours, and neutralize it with acid until the pH is 6;

[0040] (3) maleic anhydride esterification treatment: in the starch that is processed through step (2) hydroxypropylation, add the maleic anhydride that quality is starch quality 15%, maintain the pH value of system at 10 with sodium hydroxide solution After 3 hours of reaction, the pH value of the system was adjusted to 6 with maleic acid;

[0041] (4) Surface treatment: add 0.06% polyvinylpyrrolidone to the composite modi...

Embodiment 2

[0044] (1) Pretreatment: adding 95% ethanol to wheat starch to prepare starch milk with a concentration of 25% wt;

[0045] (2) Hydroxypropylation treatment: in the starch after the pretreatment of step (1), add under stirring the quality of the starch is 2% potassium hydroxide (for sodium hydroxide aqueous solution, the mass concentration is 45%) and the quality of the starch 100% propylene oxide, seal the reactor, let it stand at room temperature for 30 minutes, heat it to 60°C, keep it warm for 20 hours, and neutralize it with acid until the pH is 8;

[0046] (3) maleic anhydride esterification treatment: in the starch that is processed through step (2) hydroxypropylation, add weight and be starch quality 50% maleic anhydride, maintain the pH value of system at 9 with sodium hydroxide solution, After 2 hours of reaction, the pH value of the system was adjusted to 7 with acid;

[0047] (4) Surface treatment: add 0.07% glyoxal to the composite modified starch prepared in ste...

Embodiment 3

[0050] (1) Pretreatment: adding 95% ethanol to sodium hypochlorite oxidized cornstarch to prepare starch milk with a concentration of 50% wt;

[0051] (2) Hydroxypropylation treatment: in the starch after step (1) pretreatment, stir and add the sodium hydroxide of starch quality 5% (being sodium hydroxide aqueous solution, mass concentration is 40%), and starch quality 50% % propylene oxide, seal the reactor, let it stand at room temperature for 30 minutes, heat it to 60°C, keep it warm for 12 hours, and neutralize it with acid until the pH is 7;

[0052] (3) maleic anhydride esterification treatment: in the starch that is processed through step (2) hydroxypropylation, add weight and be starch quality 25% maleic anhydride, maintain the pH value of system at 11 with sodium hydroxide solution, After 4 hours of reaction, the pH value of the system was adjusted to 8 with acid;

[0053] (4) Surface treatment: add polyvinylpyrrolidone with a starch mass of 0.05% to the composite modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com