Comprehensive recycling method of electric steel making lead and zinc-contained dust

An electric furnace steelmaking and dusting technology, applied in the field of iron and steel smelting, can solve the problems of insufficient separation of lead and zinc elements, low resource utilization rate, etc., and achieve the effects of low price, wide source, and reduced process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Generally, in the electric furnace steelmaking method of producing stainless steel with iron as raw material, the electric furnace steelmaking dust generated in the smelting process is 1-2wt% of the amount of iron input. Steelmaking dust contains a lot of valuable metals such as lead, zinc, iron, nickel, chromium, etc., and also contains harmful heavy metals such as cadmium, mercury, and chromium.

[0023] The main components of common electric furnace steelmaking dust containing lead and zinc are shown in the following table:

[0024] Element

Zn

Fe

Pb

SiO 2

CaO

Al 2 o 3

Cl

F

Cd

other

Wt%

20-25

20-40

2-5

2-10

2-10

1-5

2-7

0.2-0.5

0.02-0.1

Bal.

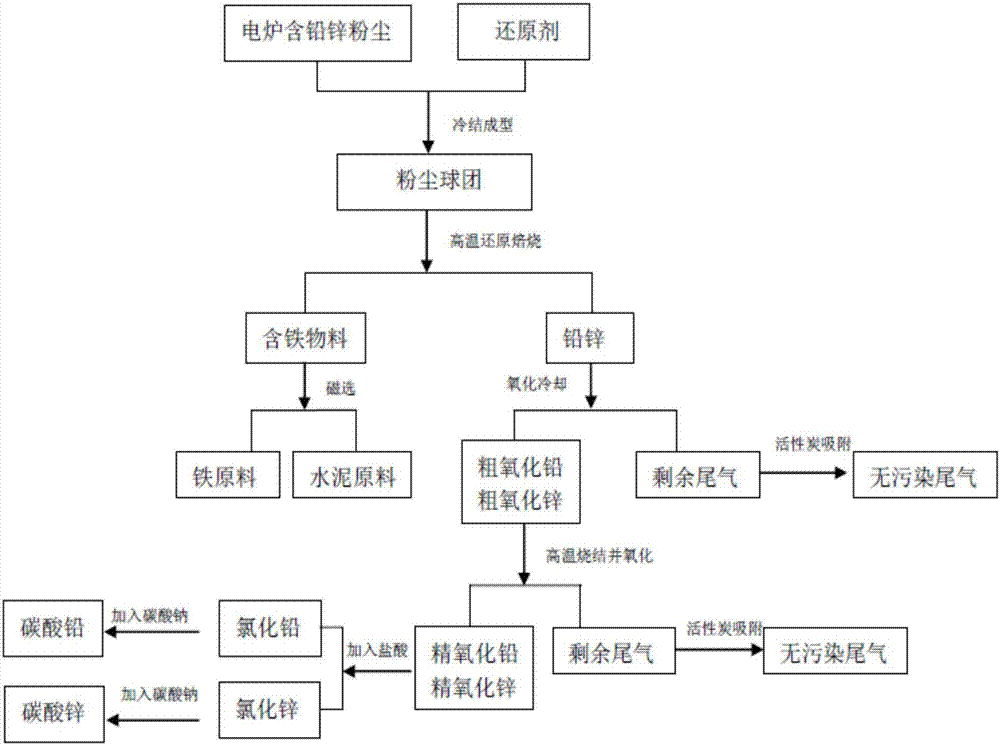

[0025] like figure 1 Shown, the comprehensive recycling method of electric furnace s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com