An environment exhaust gas zero emission cyclic treatment system

A cyclic treatment, zero-emission technology, applied in gas treatment, air quality improvement, membrane technology, etc., can solve problems such as the inability to achieve zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

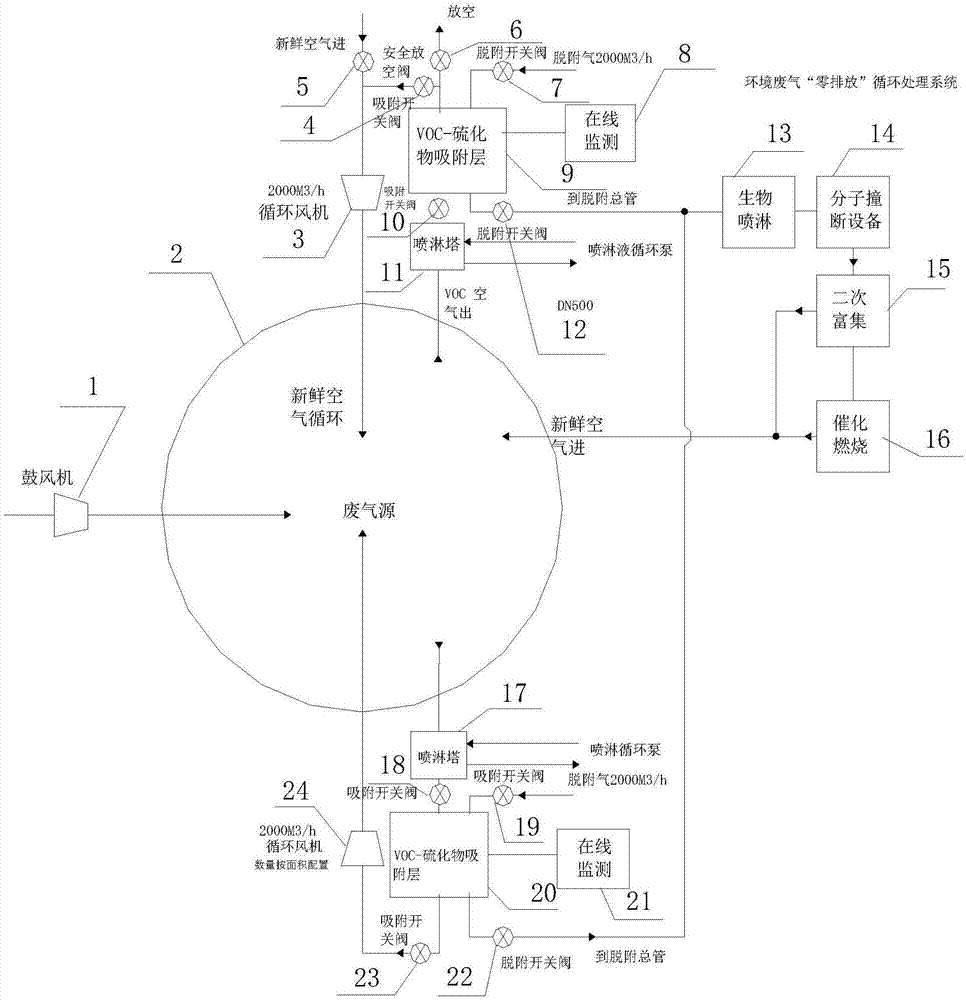

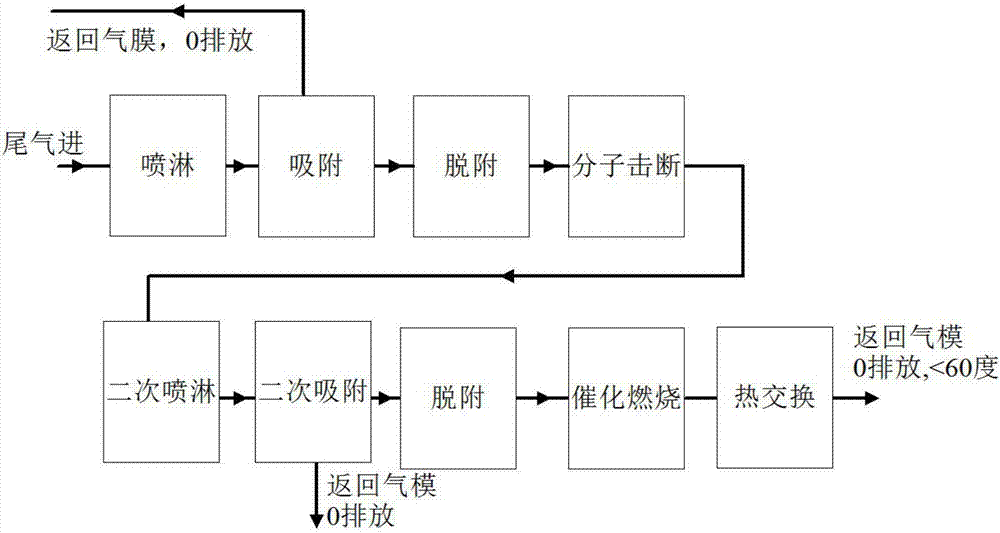

[0018] refer to figure 1 and figure 2 , the present invention is an environmental waste gas-zero emission cycle treatment system, including a waste gas collection system, a VOC-sulfide adsorption system, a VOC-sulfide desorption system, a spray desulfurization system, a VOC secondary adsorption system, and a VOC secondary desorption system. system, molecular breaking system, catalytic incineration system, tail gas on-line monitoring system, electronic control system and safety system. The tail gas on-line monitoring system is used to judge the concentration of VOC and sulfide in the gas film. It is used to control the air volume of the circulating fan in the waste gas collection system. The VOC-sulfide adsorption system is used to absorb and concentrate harmful substances in the waste gas collection system. The spray desulfurization system and molecular breaking system are used to remove toxic and harmful gases. It is desorbed from the saturated VOC-sulfide adsorbent, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap