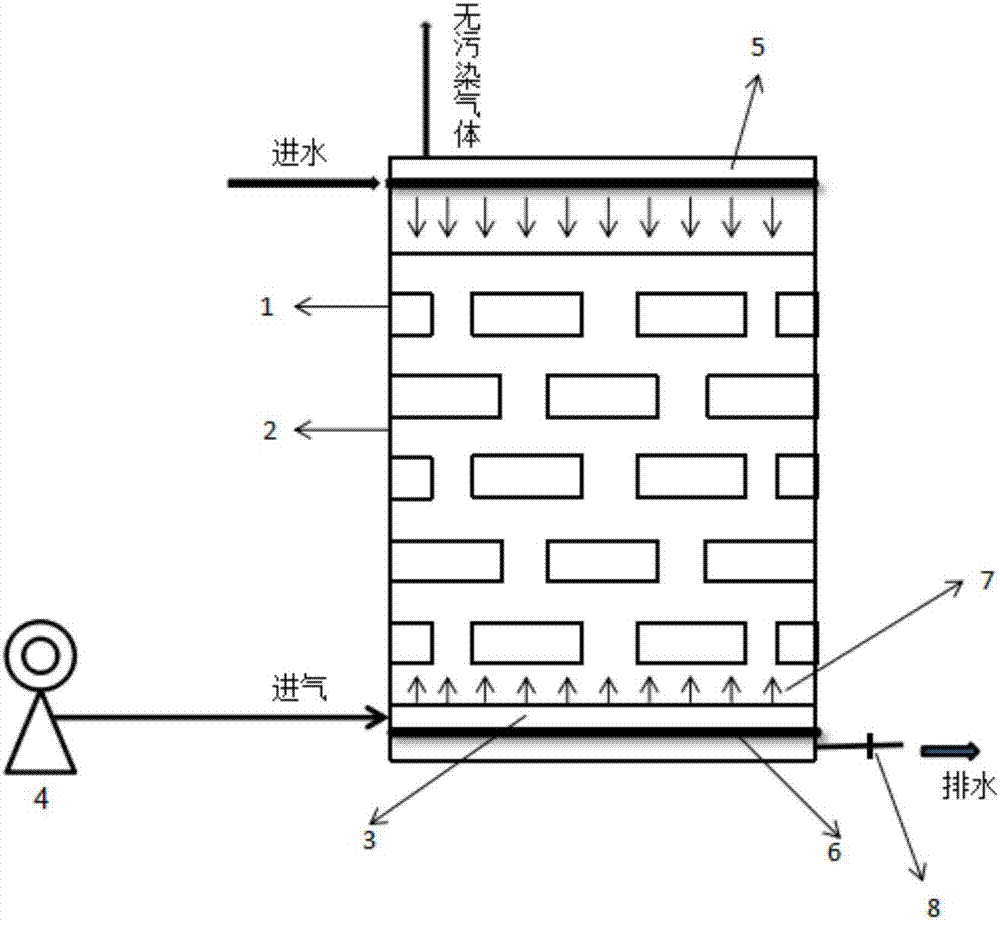

Smelly-gas treatment system based on combination of multiple filter material media and method

A treatment system and multi-filter material technology, applied in the field of biological material odor treatment, can solve the problems of reduced porosity of fillers, system clogging, etc., and achieve the effects of reducing impact load, preventing clogging, and low construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The odor generated by the sewage treatment plant enters the odor treatment system through the fan, and the intake air volume is 300m h -1 , water distribution pipe tap water drip filter capacity 9×10 -3 m -3 h -1 . By monitoring the deodorization effect of the system for 30 days, the main odor pollutant H in the odor 2 The concentration of S is (0.148~0.684) mg·m -3 Between, after being processed by the multimedia system, H 2 The concentration of S is (0.013~0.064)mg·m -3 Between, the removal rate is over 84.5%, and the average removal rate is as high as 91.8%; NH 3 The intake air concentration is (0.107~0.652)mg·m -3 Between, the average is 0.310mg·m -3 , after system purification, in (0~0.081)mg·m -3 between, with an average of 0.040mg·m -3 . Its removal rate is above 75.2%, and the average removal rate is as high as 87.8%. At the same time, the odor concentration is used as the monitoring index, and the intake odor concentration is (977-4121) OU m -3 Betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com