Alcohol precipitation tank and horizontal spiral centrifugal machine combined system

A decanter centrifuge and combined system technology, applied in centrifuges, settling tanks, feeding/discharging devices of settling tanks, etc., can solve problems such as poor filtering effect, large amount of dirt on site, hidden safety hazards, etc., and achieve improvement The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

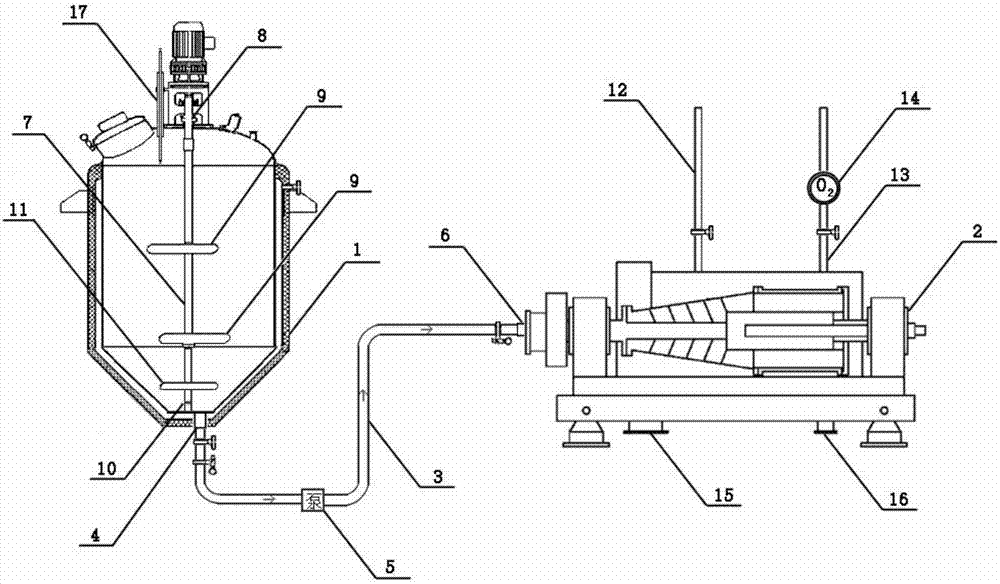

[0043] Example 1 Operation process of combined system of alcohol sinking tank and decanter centrifuge

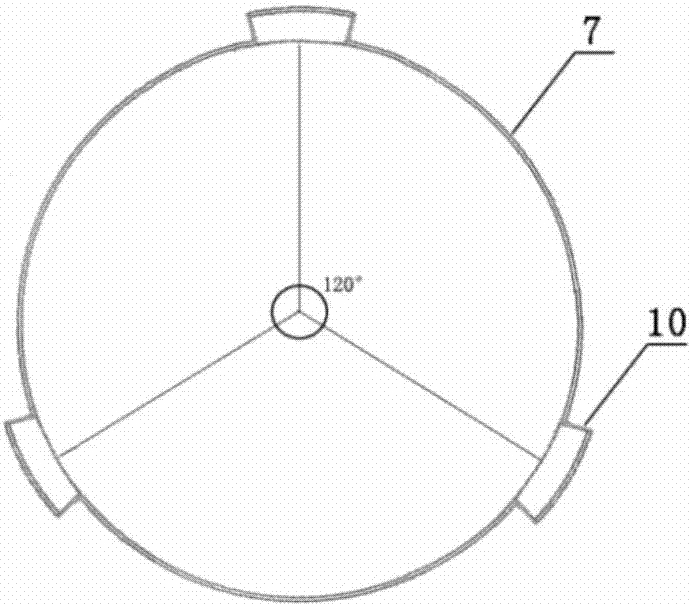

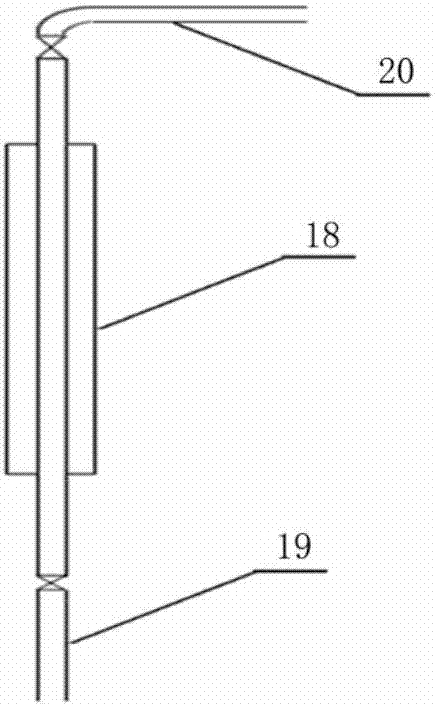

[0044] as attached figure 1 As shown, the main components of the present invention are the alcohol precipitation tank 1 and the decanter centrifuge 2, which are the same or similar in structure to the existing alcohol precipitation tank and the decanter centrifuge. Alcohol precipitation tank 1. There is a jacket on the outside of the tank, which can be fed with condensed water or low-temperature water to indirectly cool the concentrated liquid and control the temperature required for the alcohol precipitation liquid. One or two sets of main stirring paddles can be installed as needed for stirring axis 7 and parallel to the horizontal section of alcohol precipitation tank 1.

[0045] The special feature of the present invention is that the bottom discharge port 4 of the alcohol precipitation tank 1 is detachably connected with the side feed port 6 of the decanter centrifuge...

Embodiment 2

[0050] Example 2 Ethanol Centrifugal Separation Test in Chaiyin Oral Liquid Alcohol Sediment

[0051] Taking the alcohol residue of Chaiyin oral liquid described in the above description as the object of investigation, the alcohol residue is under the condition that the rotating speed of the main stirring paddle 9 is 80-140r / min, and the rotating speed of the bottom stirring paddle 11 is 600-900r / min. The obtained chaiyin oral liquid alcohol precipitate. The medicinal liquid contained in the alcohol sediment is centrifuged and recovered with the system of the present invention, and the results are as follows:

[0052] Table 2 Results of ethanol separation test in chaiyin oral liquid alcohol sediment

[0053]

[0054] The concentrated alcohol precipitate of Chaiyin Oral Liquid is a relatively loose type of alcohol precipitation, which contains a large amount of liquid medicine and ethanol. It can be seen from the test results in Table 2 that an average of 20.69kg of liquid ...

Embodiment 3

[0055] Example 3 Ethanol Centrifugal Separation Test in Anshen Bunao Liquid Sediment

[0056] The inventor took the prescription of "Anshen Bunao Liquid" in the first part of the 2015 edition of "Chinese Pharmacopoeia" as the research object, and applied the combined system of alcohol precipitation tank and decanter centrifuge of the present invention to recover alcohol precipitation liquid and ethanol from alcohol precipitation. The test of liquid phase has been studied, and the determination method and results are as follows:

[0057] Preparation of Anshen Bunao Liquid Alcohol Precipitate: Antler, Radix Polygoni Multiflori, Epimedium, Dried Ginger, Licorice, Jujube, Vitamin B1, the above seven flavors, volatile oil extracted from dried ginger, medicinal dregs and Polygonum multiflorum, Epimedium, Jujube 1. Glycyrrhizae was decocted three times with water, combined the decoction, filtered, and the filtrate was concentrated to an appropriate amount to obtain a water-extracted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com