Lactobacillus plantarum Lp1 and application thereof in preparation of feed additive

A technology of Lactobacillus plantarum, LP1, applied in the direction of bacteria used in food preparation, preservation method of animal feed raw materials, Lactobacillus, etc., can solve the problem of low soluble carbohydrate content, difficulty in making semi-dry silage of alfalfa, and low protein feed. Use value and other issues to achieve the effect of improving feed value, reducing content and increasing lactic acid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

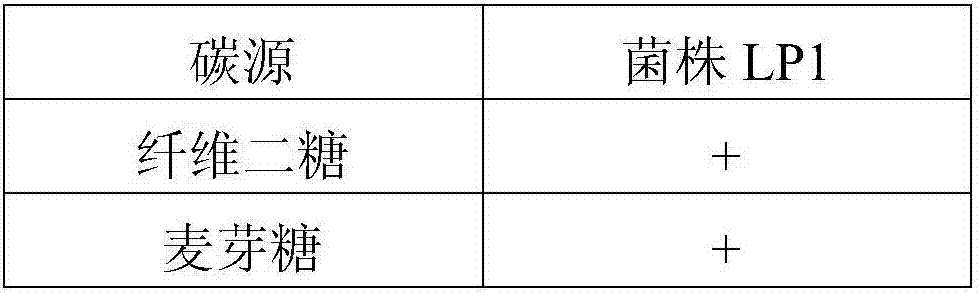

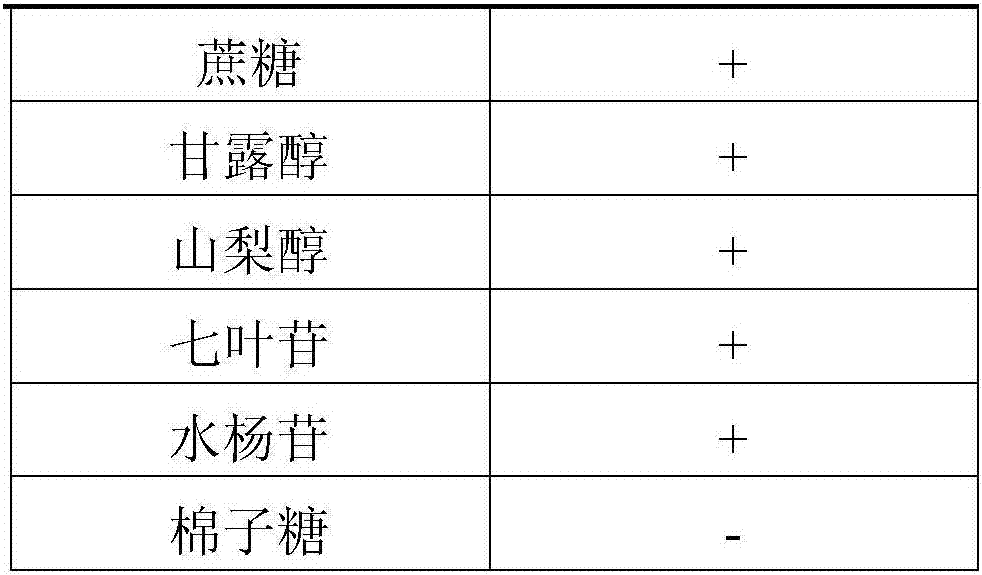

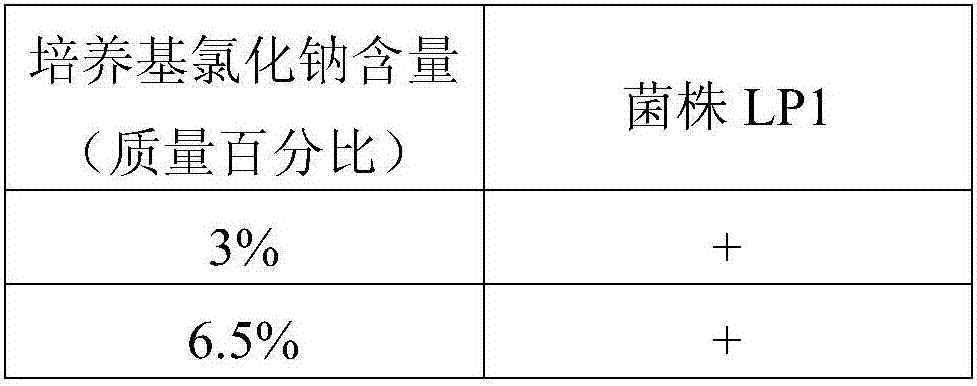

[0053] Example 1. Isolation, screening and identification of Lactobacillus plantarum LP1

[0054] 1. Isolation and screening of strains

[0055] Collect sheepskin soaking solution (the liquid after soaking raw hides in water during the production process of sheepskin) in Hohhot City, Inner Mongolia, shake it with an oscillator for 30 minutes, and use distilled water for 10 minutes. -1 -10 -6For gradient dilution, take 1mL from each dilution gradient dilution and inoculate it into a petri dish, add 10-15ml sterilized MRS solid medium, shake well, wait for it to cool and solidify, and let it stand for anaerobic culture for 48h. Pick single colonies with obvious differences in colony shape, size, color and gloss, and repeat streaking until pure colonies are obtained. Single colonies were picked for Gram staining and catalase test. All Gram-positive, catalase-negative strains were initially identified as lactic acid bacteria, and then a lactic acid bacterium with high growth an...

Embodiment 2

[0092] Embodiment 2, plant Lactobacillus (Lactobacillus plantarum) LP1 prepares alfalfa silage

[0093] 1. Bacteria powder preparation

[0094] Lactobacillus plantarum LP1 is inoculated in 10ml MRS liquid medium, 37 ℃, 250rpm shaking culture, after cultivating 2 generations, inoculate in 60ml MRS liquid medium by the inoculum size of 3% (volume ratio) (bacterial liquid initial OD 260nm =1.8), 37°C, 250rpm shaking culture for 18-24h (the final OD of bacterial solution 260nm = 4), the culture system is centrifuged, the thalline precipitation is collected, the thalline precipitation is mixed with 10ml sterilized skim milk and then freeze-dried to obtain a solid bacterial preparation, the concentration of Lactobacillus plantarum in the solid bacterial preparation is 1 × 10 12 CFUg -1 (Need to be greater than 1×10 10 CFUg -1 ).

[0095] 2. Preparation of alfalfa silage

[0096] Alfalfa: The last crop of alfalfa at the budding stage planted in Zhuozhou, Hebei was harvested on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com