Sludge Drying System Combined with Solar Energy and Biogas Combustion Radiators

A biogas combustion and sludge drying technology, applied in dryers, dryers, dryers and other directions of static materials, can solve the problems of environmental pollution, low solar energy utilization, low drying efficiency, etc., and achieve uniform temperature distribution. , saving drying energy cost, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

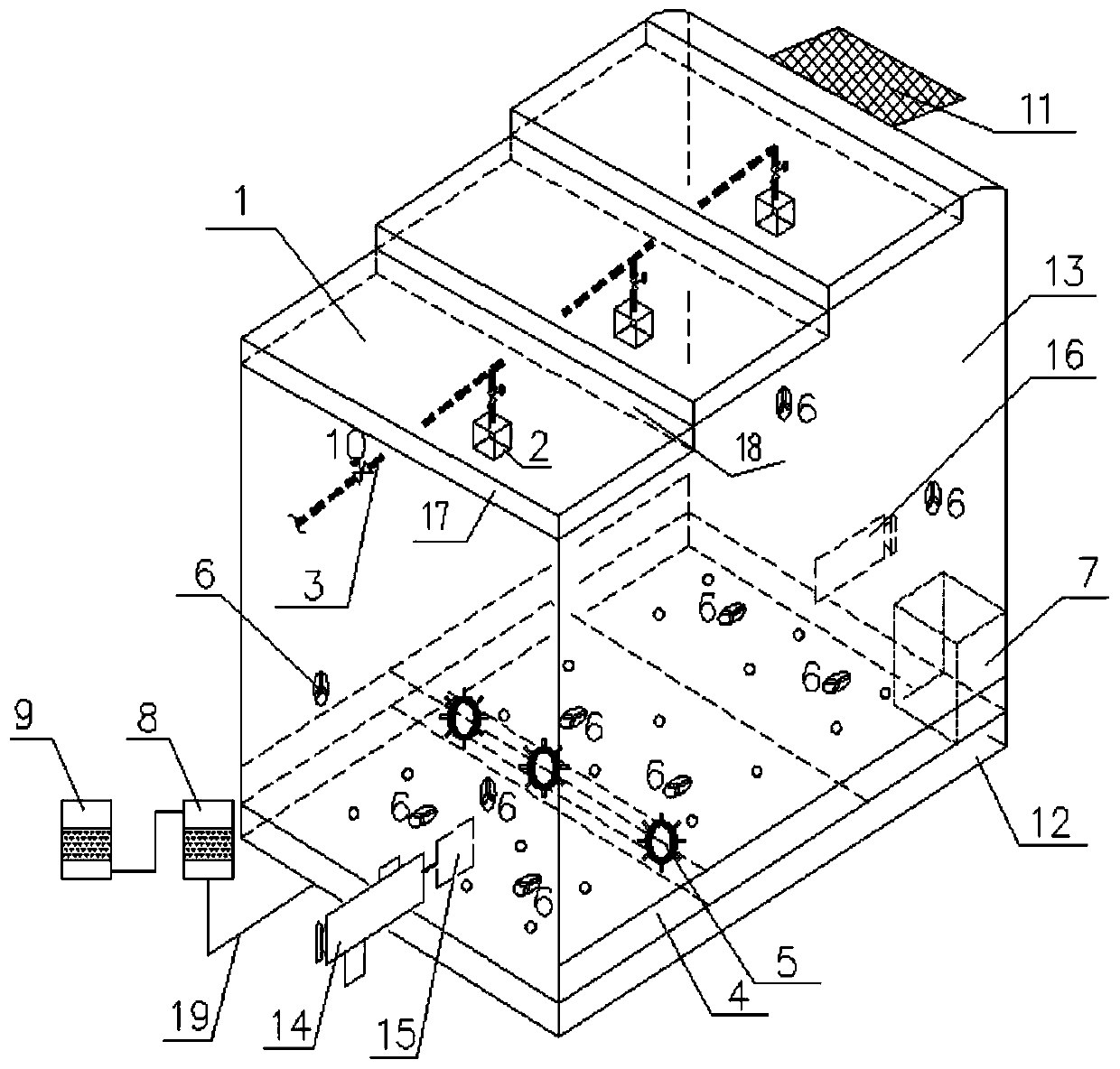

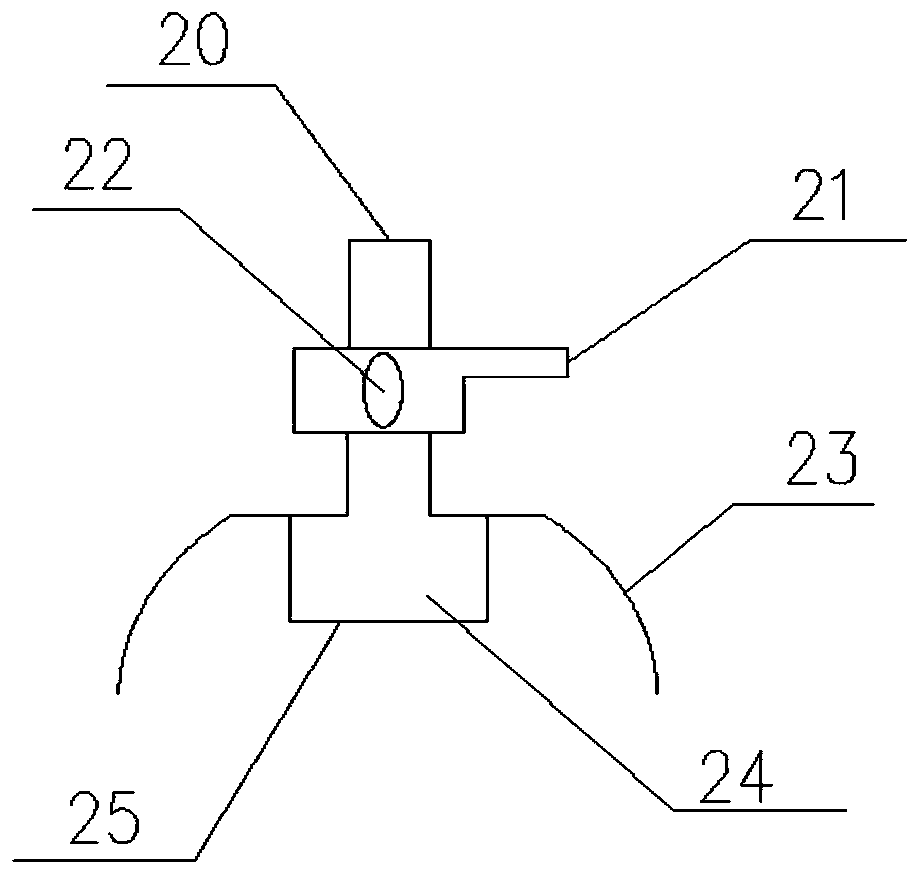

[0034] refer to figure 1 and figure 2 , a sludge drying system combined with solar energy and biogas burner, including a solar greenhouse module, a biogas burner module, an intelligent automatic control module, a sludge conveying and throwing module and a deodorization module.

[0035] The solar greenhouse module includes an enclosure structure 13, a flat-plate solar collector 1, a movable porous floor 4, a steel plate 12, an axial exhaust fan 6, and a solar photovoltaic panel 11;

[0036] The main frame of the solar greenhouse is composed of hot-dip galvanized steel pipe and steel plate, and the top is a special aluminum profile. The surrounding protective structure 13 is made of double-layer hollow pc board, which has selective transmittance to the radiation of sunlight. When the sunlight irradiates on the pc board, because it has a large penetration ratio to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com