Co3O4/MnO2/PPy nanowire array and preparation method thereof

A nanowire array and nanowire technology, applied in the field of electrochemistry, can solve problems such as difficult to meet high-performance supercapacitors, and achieve the effects of high specific surface area, high ion transmission performance, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a Co 3 o 4 / MnO 2 The preparation method of / PPy nanowire array comprises:

[0039] A) Place the substrate in cobalt salt, ammonium salt, CO(NH 2 ) 2 The mixed solution is hydrothermally reacted and annealed to obtain Co 3 o 4 nanowire arrays;

[0040] B) Using a three-electrode system, with Co 3 o 4 The nanowire array is the working electrode, the platinum is the counter electrode, the saturated calomel electrode is the reference electrode, and the mixture of one or more of sodium salt and potassium salt and manganese salt is the electrolyte solution. 3 o 4 Deposition of MnO on the surface of nanowires 2 shell, to get Co 3 o 4 / MnO 2 Core-shell nanowire arrays;

[0041] C) Using a three-electrode system, with Co 3 o 4 / MnO 2 The core-shell structure nanowire array is the working electrode, the platinum is the counter electrode, the saturated calomel electrode is the reference electrode, and the mixture of pyrrole, benzenesulfonate...

Embodiment 13D

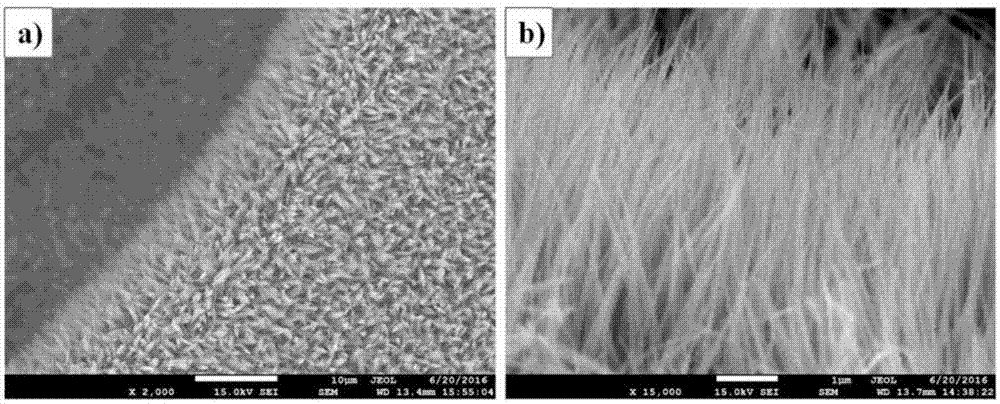

[0073] Example 13D Co 3 o 4 Fabrication of Nanowire Arrays

[0074] 5mmol Co(NO 3 ) 2 ·6H 2 O was ultrasonically dissolved in 70 mL of deionized water, and then 10 mmol of NH was added to the solution 4 F and 25mmol CO(NH 2 ) 2 , after magnetically stirring evenly, transfer the solution to a hydrothermal kettle, and clean the cleaned nickel foam (size: 1cm×2cm; pretreatment: ultrasonic cleaning twice with 3mol / L HCl and acetone, and then deionized water Clean it up, put it in ethanol and seal it for storage for later use) into the prepared solution, and then put the hydrothermal kettle into a constant temperature oven at 120°C for 5 hours of reaction. The reacted sample was taken out, washed repeatedly with deionized water and dried, then annealed at 350 °C for 2 h to obtain 3D Co 3 o 4 nanowire arrays, the results are as figure 1 as shown, figure 1 Co of different magnifications prepared for Example 1 of the present invention 3 o 4 SEM images of nanowire arrays. ...

Embodiment 23D

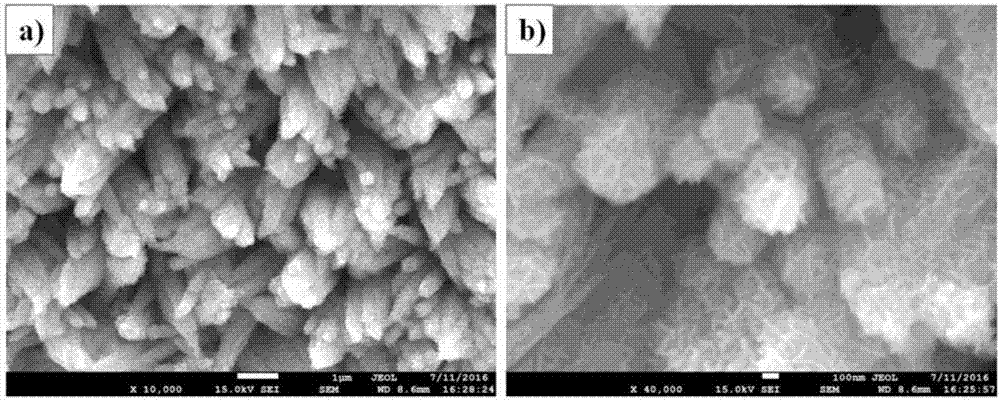

[0075] Example 23D Co 3 o 4 / MnO 2 Fabrication of core-shell nanowire arrays

[0076] Using a standard three-electrode system, the 3D Co obtained in Example 1 3 o 4 The nanowire array is the working electrode, the platinum is the counter electrode, the saturated calomel electrode is the reference electrode, and the mixed solution of manganese acetate and sodium sulfate is the electrolyte, wherein the concentrations of manganese acetate and sodium sulfate are both 0.1mol / L. Electrochemical deposition was carried out by potentiostatic method. The deposition voltage was 1.0V, and the deposition time was 300s. Proceedings 3D Co 3 o 4 / MnO 2 The morphology of the core-shell nanowire array is as follows: figure 2 as shown, figure 2 Co prepared with different magnifications for Example 2 of the present invention 3 o 4 / MnO 2 SEM images of core-shell nanowire arrays. Depend on figure 2 It can be seen that in each Co 3 o 4 The surface of the nanowires is evenly coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com