A liquid metal thermally conductive filler and preparation method thereof

A technology of thermal conductive filler and liquid metal, which is applied in the direction of heat exchange materials, chemical instruments and methods, adhesive additives, etc. The coating effect is not ideal and other problems, to achieve the effect of saving preparation cost, good compatibility and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

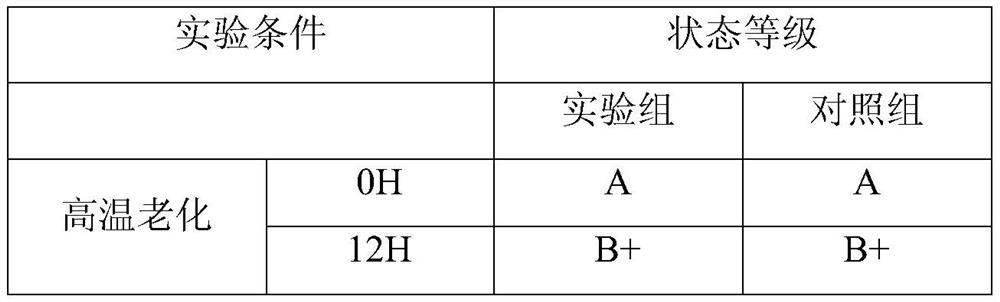

Examples

Embodiment Construction

[0029] The invention will be further described below. For the convenience of description, the equipment in the present invention omits necessary or conventional operation steps or conditions, and those skilled in the art can make arbitrary adjustments according to the needs of the reaction. Under the condition of no conflict, the features of the various embodiments in the solution of the present invention can be combined with each other.

[0030] 1. Preparation of materials

[0031] All raw materials of the present invention are commercially available or can be obtained by conventional methods. The following commercially available or self-made raw materials (preparation methods are conventional methods) are adopted in the examples of this case:

[0032] Low melting point metals or alloys (commercially available): indium gallium alloy: melting point 12°C; indium gallium tin alloy: melting point 10°C;

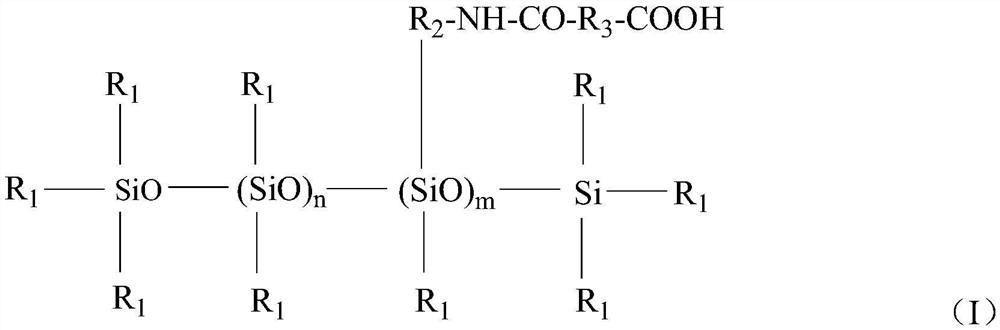

[0033] Side chain carboxyl-containing polysiloxane (self-made): add octam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com