High temperature-resistant low-carbon cleaning-type lubricating oil

A technology of high temperature resistance and lubricating oil, applied in the field of lubricating oil, can solve the problems of restricting the development of bio-based lubricating oil, affecting the lubricating performance of lubricating oil, shortening the service life of lubricating oil, etc. The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

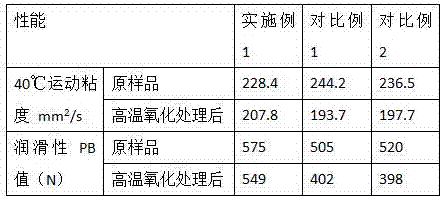

Examples

Embodiment 1

[0016] Embodiment 1: A high-temperature-resistant low-carbon clean lubricating oil is composed of the following raw materials in parts by weight: base oil: 100 parts of modified palm olein, 8 parts of pentaerythritol ester, and 2 parts of polyalphaolefin; modified additives: 2 parts of alkaline neutralizer, 0.3 parts of T704 zinc naphthenate, 3 parts of sulfurized alkylphenate calcium, 0.4 parts of heptadecenyl imidazoline, 2 parts of ethylene glycol amide oleic acid borate, castor oil alkanolamide 1 part of boric acid ester, 0.5 part of benzotriazole fatty acid amine salt, 0.2 part of alkanolamide, 4 parts of isooctyl palmitate.

[0017] Further, the preparation method of the modified palm olein is as follows: take the palm olein dried with anhydrous calcium chloride and place it in a reaction vessel, add toluene twice the volume of the palm olein, and then dropwise add 1% Potassium hydroxide-methanol standard solution with the volume of palm olein was incubated at 65°C for 4...

Embodiment 2

[0022] Embodiment 2: A high-temperature-resistant low-carbon clean lubricating oil, consisting of the following raw materials in parts by weight: base oil: 100 parts of modified palm olein, 5 parts of pentaerythritol ester, 1 part of polyalphaolefin; modified additives: 0.5 parts of alkaline neutralizer, 0.2 parts of T704 zinc naphthenate, 2 parts of sulfurized calcium alkylphenate, 0.2 parts of heptadecenyl imidazoline, 1 part of ethylene glycol amide oleic acid borate, castor oil alkanolamide 0.5 part of boric acid ester, 0.3 part of benzotriazole fatty acid amine salt, 0.1 part of alkanolamide, 2 parts of isooctyl palmitate.

[0023] Further, the preparation method of the modified palm olein is as follows: take the palm olein dried with anhydrous sodium sulfate and place it in a reaction vessel, add toluene twice the volume of the palm olein, and then add 1% palm olein dropwise Potassium hydroxide-methanol standard solution with the volume of liquid oil was incubated at 70°...

Embodiment 3

[0025] Embodiment 3: A high-temperature-resistant low-carbon clean lubricating oil is composed of the following raw materials in parts by weight: base oil: 100 parts of modified palm olein, 10 parts of pentaerythritol ester, and 3 parts of polyalphaolefin; modified additives: 3 parts of alkaline neutralizer, 0.5 parts of T704 zinc naphthenate, 4 parts of sulfurized alkylphenate calcium, 0.6 parts of heptadecenyl imidazoline, 3 parts of ethylene glycol amide oleic acid borate, castor oil alkanolamide 1.5 parts of borate ester, 0.7 part of benzotriazole fatty acid amine salt, 0.3 part of alkanolamide, 6 parts of isooctyl palmitate.

[0026] Further, the preparation method of the modified palm olein is as follows: take the palm olein dried with anhydrous calcium chloride and place it in a reaction vessel, add toluene twice the volume of the palm olein, and then dropwise add 1% Potassium hydroxide-methanol standard solution with the volume of palm olein was incubated and reacted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com