Method for constructing micro-nano structure with antibacterial function on surface of metal substrate

A metal substrate, micro-nano structure technology, applied in the direction of metal material coating process, nanotechnology, liquid chemical plating, etc., can solve the problems of reduced antibacterial performance, poor antifungal performance, affecting long-term performance, etc., and achieves regularity. High, evenly distributed, efficient bactericidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of the antibacterial functionalized coating on the bottom surface of the stainless steel plate base includes the following steps:

[0025] A. Preparation of ZnO seed crystal layer: cut austenitic 304 stainless steel plate into 5cm×5cm size, immerse the sample in acetone, deionized water and absolute ethanol in turn, ultrasonically clean for 10min, then dry, anneal at 250 ℃ and cool, Subsequently, a zinc acetate ethanol solution was prepared, and the stainless steel plate was immersed in the zinc acetate ethanol (10 mmol / L) solution for 4 minutes, and then the liquid surface was pulled out at a constant speed of 5 cm / min, and dried in an oven at 70 °C for 5 minutes. Put it into a muffle furnace for annealing at 300°C for 1 h, and after cooling, a stainless steel plate with ZnO nanocrystals evenly distributed on the surface is obtained.

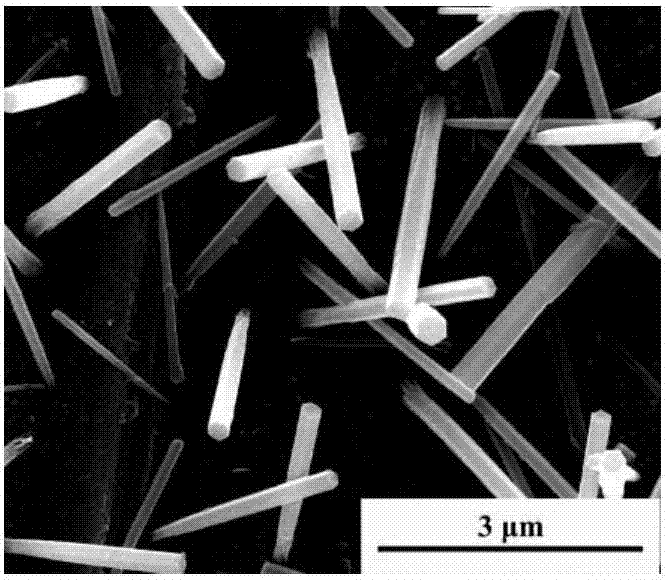

[0026] B. Hydrothermal synthesis of ZnO arrays: respectively prepare deionized aqueous solutions of equal volum...

Embodiment 2

[0029] The preparation process of the antibacterial functionalized coating on the surface of the stainless steel plate base includes the following steps:

[0030] A. Preparation of ZnO seed crystal layer: cut austenitic 304 stainless steel plate into a size of 5cm×5cm, immerse the sample in acetone, deionized water and absolute ethanol in turn, ultrasonically clean for 10min, then dry, anneal at 400 ℃ and cool, Subsequently, a zinc acetate ethanol solution was prepared, and 2.5 vol% deionized water was added. After mixing evenly, the stainless steel plate was immersed in the zinc acetate ethanol (40 mmol / L) solution for 4 min, and then the liquid surface was pulled out at a uniform speed of 7 cm / min. Place in a 50°C oven to dry for 5 minutes, then put the steel sheet into a muffle furnace for 400°C annealing for 5 minutes, and then perform the pull-up annealing process again. A stainless steel plate with ZnO nanocrystals evenly distributed on the surface is obtained.

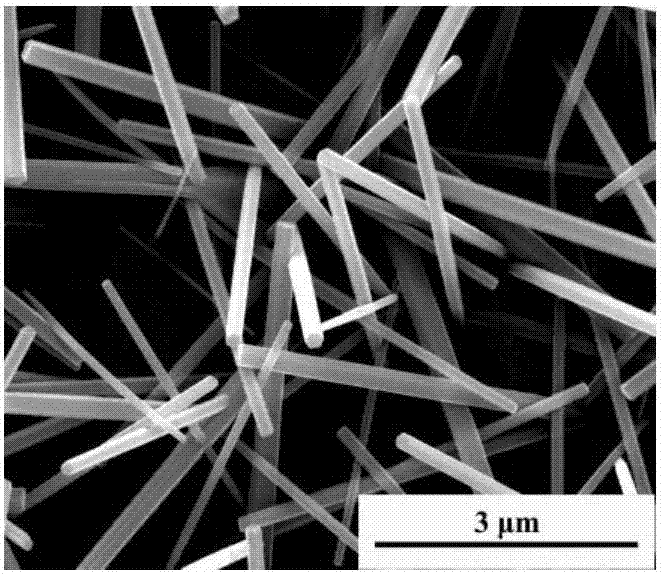

[0031]...

Embodiment 3

[0033] The preparation process of the antibacterial functionalized coating on the surface of the aluminum alloy plate base includes the following steps:

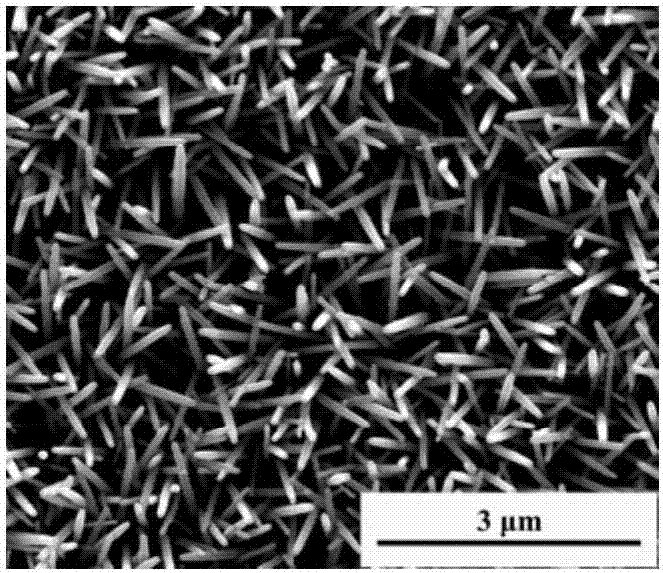

[0034]A. Preparation of ZnO seed crystal layer: The aluminum alloy plate was cut into a size of 5cm×5cm, the sample was immersed in acetone, deionized water and anhydrous ethanol in turn, ultrasonically cleaned for 10min, dried, annealed at 400 °C and cooled, and then prepared with acetic acid Zinc ethanol solution and 0.5vol% deionized water were added to make the final concentration 50mmol / L. After mixing evenly, the aluminum alloy plate was immersed in the zinc acetate ethanol solution for 1min, and then pulled out of the liquid surface at a uniform speed of 2cm / min. And placed in a 50 ℃ oven to dry for 5 minutes, and then the aluminum alloy plate was placed in a muffle furnace at 450 ℃ for 5 minutes annealing and then cooled. After the sample was cooled, the pull-up annealing process was performed again. After 4 cycles o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com