Polycrystalline silicon wafer back polishing technology

A backside polishing, polycrystalline silicon wafer technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of increased reflection, low absorption, rough etching on the back of the battery, etc., to improve short-circuit current and, The effect of reducing the probability of damage and improving the light absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

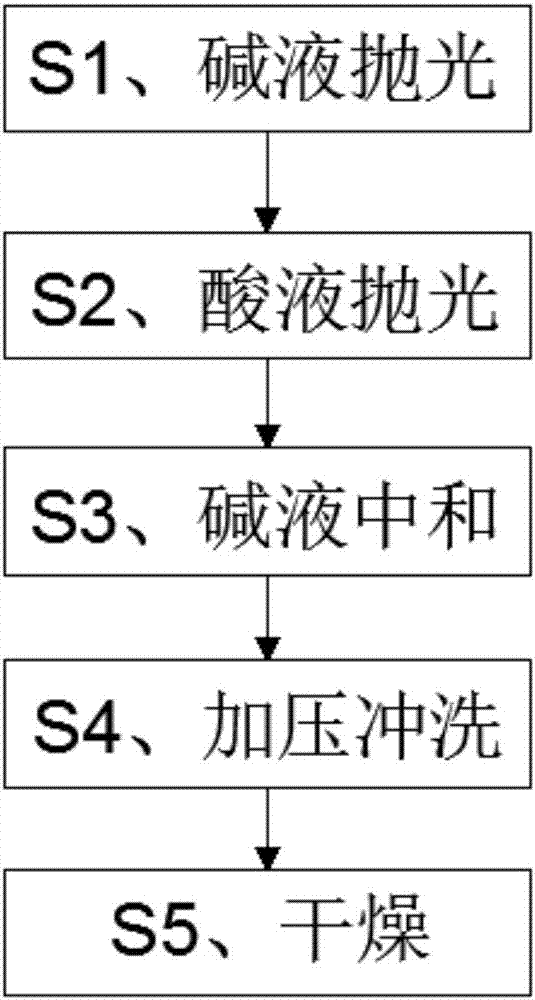

[0027] A process for polishing the back of a polysilicon wafer, comprising the following steps:

[0028] Step S1, lye polishing: In order to only soak the back of the silicon wafer, use a commonly used chain etching machine, add strong lye to the chain etcher, adjust the height of the strong lye in the machine tank, use the viscous roller to only The back of the silicon wafer is soaked, and the strong alkali solution is a mixed solution of sodium hydroxide and potassium hydroxide, wherein the mass concentration of the sodium hydroxide solution is 15%, and the mass concentration of the potassium hydroxide solution is 10%, and the sodium hydroxide and potassium hydroxide The volume ratio of potassium is 1:0.75, soak the back of the silicon wafer for 10s, and control the soaking temperature to 10°C throughout the process.

[0029] Step S2, acid polishing: take out the silicon wafer after soaking in step S1, and then use the chain etching machine of the same model as step S1, add ...

Embodiment 2

[0035] A process for polishing the back of a polysilicon wafer, comprising the following steps:

[0036] Step S1, lye polishing: In order to only soak the back of the silicon wafer, use a commonly used chain etching machine, add strong lye to the chain etcher, adjust the height of the strong lye in the machine tank, use the viscous roller to only The back of the silicon wafer is soaked, and the strong alkali solution is a mixed solution of sodium hydroxide and potassium hydroxide, wherein the mass concentration of the sodium hydroxide solution is 15%, and the mass concentration of the potassium hydroxide solution is 10%, and the sodium hydroxide and potassium hydroxide The volume ratio of potassium is 1:0.75, soak the back of the silicon wafer for 20s, and control the soaking temperature to 5°C throughout the process.

[0037] Step S2, acid polishing: take out the silicon wafer after soaking in step S1, and then use the chain etching machine of the same model as step S1, add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com