Pet calcium paste and preparation method thereof

A pet, milk calcium technology, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of not achieving good calcium absorption effect, imbalance of calcium intake and absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

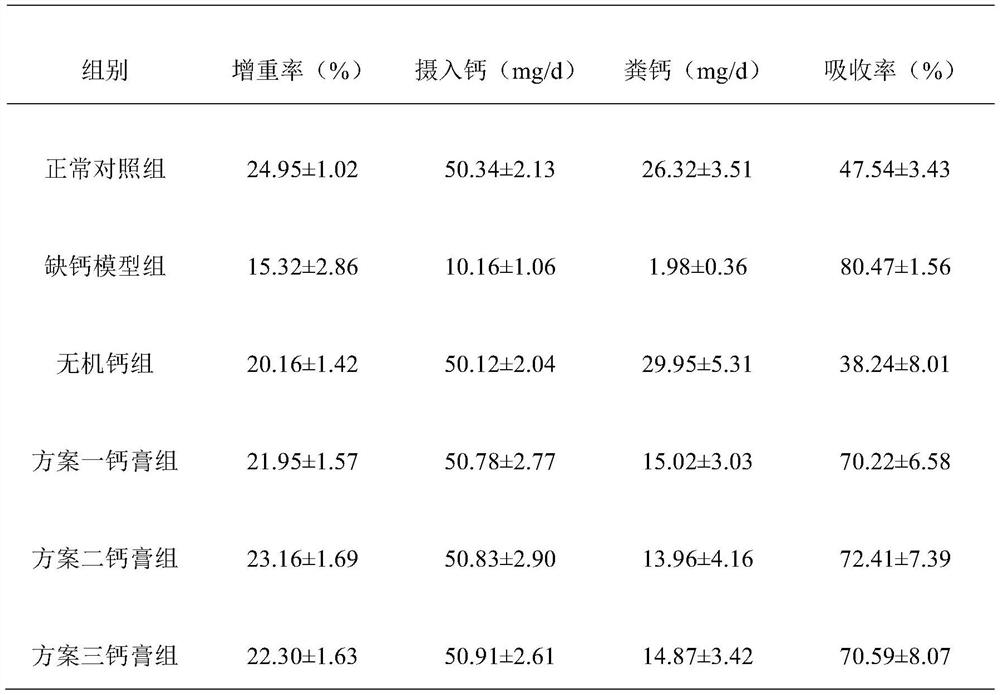

Embodiment 1

[0027] Take by weighing raw materials respectively, and raw material total amount is 100 kilograms. Among them: 5 kg of milk calcium, 5 kg of calcium hydrogen phosphate, 1 kg of fructooligosaccharide, 0.5 kg of L-lysine hydrochloride, 1 kg of hydrolyzed casein, 1.5 kg of magnesium sulfate, 0.38 kg of zinc sulfate, and 0.02 kg of vitamin A , 0.00004 kg of vitamin D3, 0.15 kg of vitamin E, 4 kg of sodium carboxymethyl cellulose, 15 kg of animal oil, 10 kg of flavoring agent, 1 kg of milk powder, 10 kg of white sugar, 5 kg of maltose, 0.15 kg of sodium benzoate, and 40.29996 kg of water Kilogram.

[0028] Concrete preparation process is as follows:

[0029] (1) Milk calcium, calcium hydrogen phosphate, fructooligosaccharides, L-lysine hydrochloride, hydrolyzed casein, animal oil, seasoning, milk powder, white sugar, and maltose are weighed and put into the batching tank according to the formula. Proportionally add water and stir to form a slurry; weigh the sodium carboxymethyl ...

Embodiment 2

[0034] Take by weighing raw materials respectively, and raw material total amount is 100 kilograms. Among them, 14 kg of milk calcium, 10 kg of calcium hydrogen phosphate, 3 kg of fructooligosaccharide, 1.1 kg of L-lysine hydrochloride, 2 kg of hydrolyzed casein, 1.5 kg of magnesium sulfate, 0.38 kg of zinc sulfate, 0.02 kg of vitamin A, Vitamin D3 0.00004 kg, vitamin E 0.15 kg, sodium carboxymethyl cellulose 2.1 kg, animal oil 8 kg, flavoring agent 2 kg, milk powder 3 kg, sugar 5 kg, maltose 2 kg, sodium benzoate 0.15 kg, water 45.59996 kg. The preparation process is the same as in Example 1.

Embodiment 3

[0036] Take by weighing raw materials respectively, and raw material total amount is 100 kilograms. Among them, 20 kg of milk calcium, 20 kg of calcium hydrogen phosphate, 10 kg of fructooligosaccharide, 3 kg of L-lysine hydrochloride, 5 kg of hydrolyzed casein, 1.5 kg of magnesium sulfate, 0.38 kg of zinc sulfate heptahydrate, and 0.02 kg of vitamin A kg, vitamin D3 0.00004 kg, vitamin E 0.15 kg, sodium carboxymethyl cellulose 0.5 kg, animal oil 5 kg, flavoring agent 1 kg, milk powder 6 kg, sugar 1 kg, maltose 0.5 kg, sodium benzoate 0.15 kg, water 25.79996 Kilogram. The preparation process is the same as in Example 1.

[0037] The components involved in the above Examples 1 to 3 are all commercially available, wherein the flavoring agent is a commercially available fifth-generation compound flavor enhancer, and the commercially available fifth-generation compound flavor enhancer is commercially available. Flavoring agents are composed of nucleotide salts, organic acid salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com