Recovery treatment method for wastewater containing organic matters

A technology for recycling and processing organic matter, which is used in the recycling and processing of metallurgical wastewater, chemical industry, and petroleum fields, and can solve the problems of excessive COD, difficult cleaning, and short membrane life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of waste water containing organic matter with a pH value of 1.5, the volume of waste water is 10L, the concentration of COD is 568mg / L, and 10g of solid dolomite with a particle size of 5μm is used to treat the waste water containing organic matter, wherein the solid-liquid mass ratio of solid dolomite to waste water 1:1000.

[0046] The treatment process is carried out at 10° C. by means of air stirring. Wherein, the stirring time is 60min, and the pH value at the end of the reaction is 4.5. The stirred mixed slurry was directly filtered at 10° C. to obtain a liquid phase and a solid slag.

[0047] The organic matter and water layer in the liquid phase are clearly separated, and the upper organic phase is directly separated and recovered. The residual COD concentration in the water phase is 34.0mg / L, and the organic matter removal rate reaches 94.0%.

Embodiment 2 to Embodiment 30

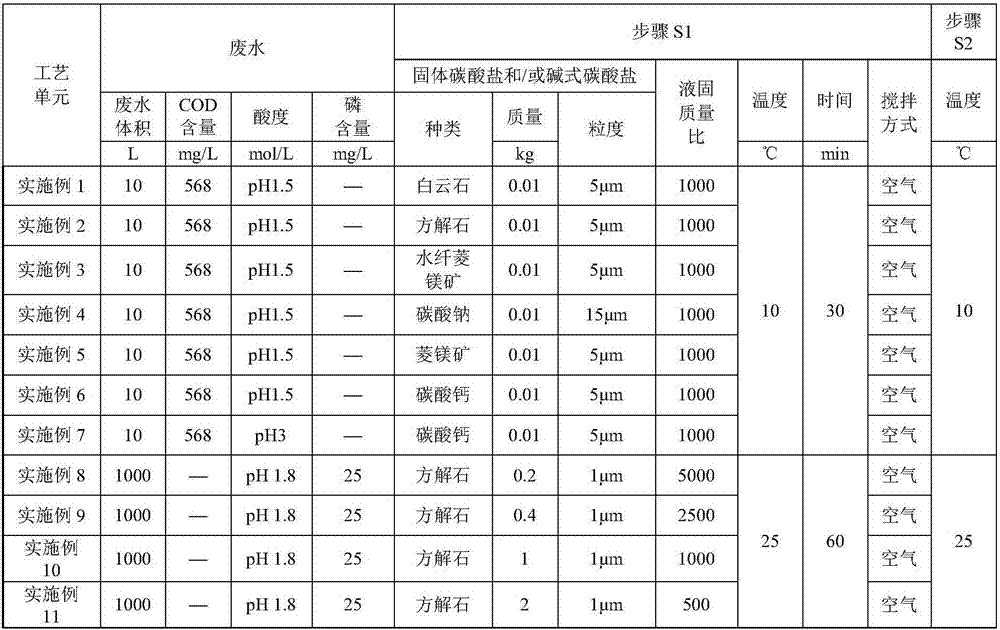

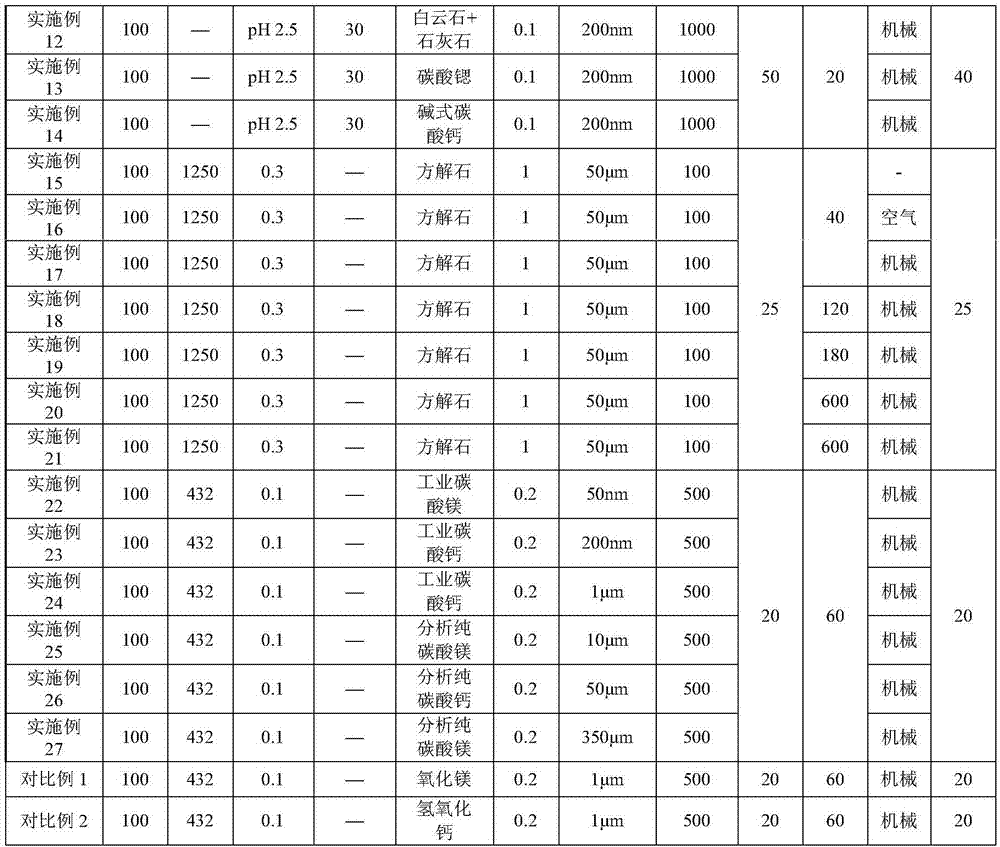

[0049] Examples 2 to 7 adopt the same or similar steps as in Example 1 to treat a kind of waste water containing organic matter from a chemical plant, and directly filter the mixed slurry obtained after treatment to obtain liquid phase and solid slag. The specific treatment The parameter conditions in the process are shown in Table 1.

[0050] Examples 8 to 14 adopt the same or similar steps as in Example 1 to treat a kind of ionic ore leach solution, centrifugal extraction and enrichment raffinate, and directly filter the mixed slurry obtained after treatment to obtain liquid phase and solid slag , and the parameter conditions in the specific processing process are shown in Table 1.

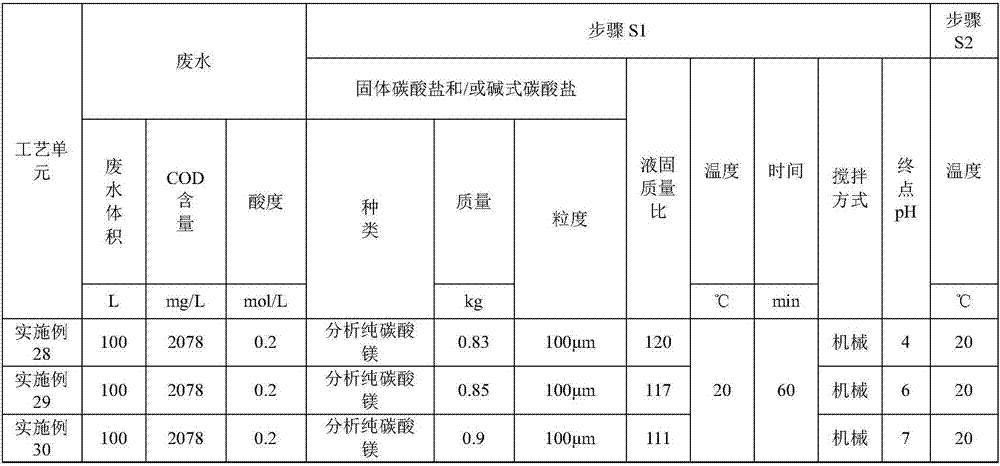

[0051]Examples 15 to 30 adopt the same or similar steps as in Example 1 to treat an acidic wastewater containing organic matter from a smelting and separation plant. For the mixed slurry obtained after treatment, Examples 18-21 adopted the method of natural sedimentation for 0.5h, 1h, 10h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com