High-Q-value lithium-based microwave medium material prepared through Mg/Nb-codoping

A microwave dielectric material and lithium-based technology, applied in the field of ceramic compositions, can solve the problems of low volume density, microcracks, affecting Qf value, etc., and achieve the effects of wide application prospects, low dielectric loss, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

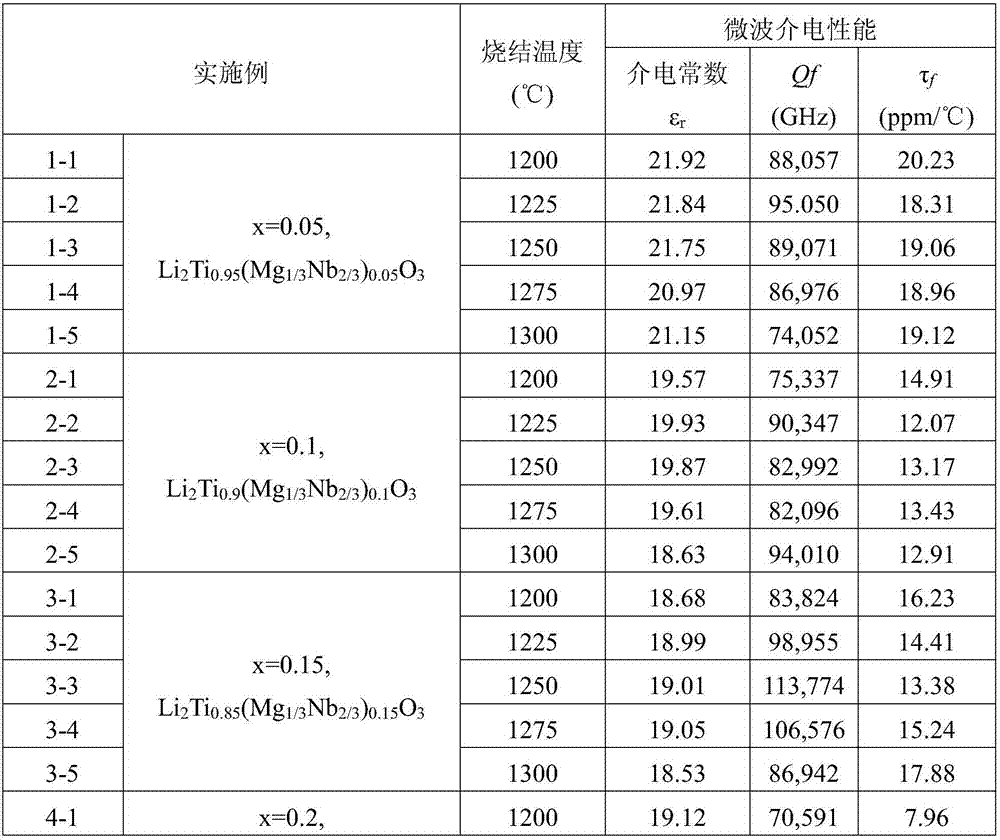

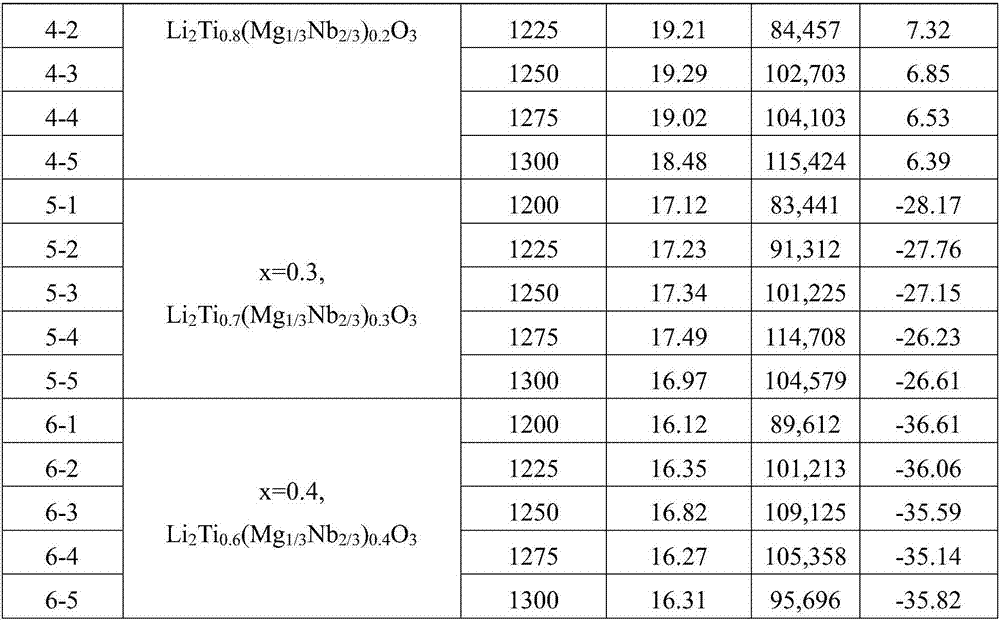

Examples

Embodiment Construction

[0018] The present invention uses Li with a purity greater than 99% 2 CO 3 、TiO 2 , MgO and Nb 2 o 5 As the starting material, microwave dielectric materials were prepared by solid phase method. The specific implementation steps are as follows:

[0019] (1) Will Li 2 CO 3 、TiO 2 , MgO and Nb 2 o 5 According to the stoichiometric formula Li 2 Ti 1-x (Mg 1 / 3 Nb 2 / 3 ) x o 3 , where x = 0.05-0.4 for batching, put the powder into a polyester ball mill tank, add absolute ethanol and zirconium balls, and ball mill for 4-24 hours;

[0020] A planetary ball mill is used for ball milling, and the speed of the ball mill is 400 rpm;

[0021] (2) Put the ball-milled powder in step (1) into a drying oven, dry at 100-120°C for 4-6 hours, and then pass through a 40-mesh sieve;

[0022] (3) Put the powder sieved in step (2) into an alumina crucible and put it in a medium-temperature furnace, pre-fire it at 700-900°C, keep it warm for 2-8 hours, and then pass it through a 40-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com