Method for preparing functional composite water-soluble fertilizer

A functional, water-soluble technology, used in organic fertilizers, liquid fertilizers, fertilizer mixtures, etc., can solve the problems of low crop yield, single function, low fertilizer absorption efficiency, etc., and achieve improved immunity, strong expansion performance, and high capillary activity. and the effect of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

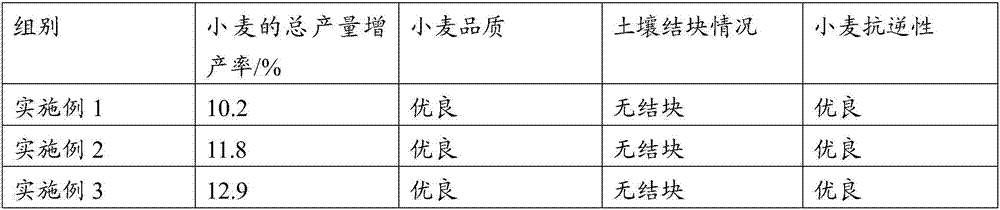

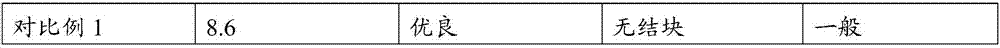

Examples

Embodiment 1

[0020] A kind of preparation method of functional compound water-soluble fertilizer, described preparation method step is as follows:

[0021] Step 1. Take 50 parts by mass of kelp and soak it in water, then add 5 parts by mass of soda ash, react at a temperature of 40°C for 6h, add 100 parts by mass of water to dilute and filter to obtain a sodium alginate solution, and then add 8 parts by mass of 10wt.% A calcium chloride aqueous solution is used for calcification reaction, after 2 hours, 10 parts by mass of 8wt.% hydrochloric acid solution is used for decalcification reaction, after 0.5 hours of reaction, 50 parts by mass of water is added for washing, and after washing, dehydration is carried out until the water content is 60wt.%.

[0022] Step 2. Add 13 parts by mass of potassium humate, 2 parts by mass of citric acid and 50 parts by mass of water to the aqueous alginic acid prepared in step 1 and mix uniformly at a temperature of 70°C to obtain the first mixed solution; ...

Embodiment 2

[0026] A kind of preparation method of functional compound water-soluble fertilizer, described preparation method step is as follows:

[0027] Step 1. Take 70 parts by mass of kelp and soak it in water, then add 10 parts by mass of soda ash, react at a temperature of 50°C for 9h, add 150 parts by mass of water to dilute and filter to obtain a sodium alginate solution, then add 12 parts by mass of 15wt.% Carry out calcification reaction with calcium chloride aqueous solution, carry out decalcification reaction with 15 parts by mass of 10wt.% hydrochloric acid solution after 4 hours, add 60 parts by mass of water after reaction for 1 hour to wash, dehydrate after washing until the water content is 68wt.% for later use;

[0028] Step 2. Add 18 parts by mass of potassium humate, 5 parts by mass of citric acid and 55 parts by mass of water to the aqueous alginic acid prepared in step 1 and mix uniformly at a temperature of 80° C. to obtain the first mixed solution;

[0029] Step 3....

Embodiment 3

[0032] A kind of preparation method of functional compound water-soluble fertilizer, described preparation method step is as follows:

[0033] Step 1. Take 60 parts by mass of kelp and soak it in water, then add 7 parts by mass of soda ash, react at a temperature of 45°C for 7h, add 125 parts by mass of water to dilute and filter to obtain a sodium alginate solution, and then add 10 parts by mass of 12wt.% Carry out calcification reaction with calcium chloride aqueous solution, carry out decalcification reaction with 13 parts by mass of 9wt.% hydrochloric acid solution after 3 hours, add 55 parts by mass of water after reaction for 1 hour to wash, dehydrate after washing to water content of 64wt.% for later use;

[0034] Step 2. Add 16 parts by mass of potassium humate, 4 parts by mass of citric acid and 53 parts by mass of water to the aqueous alginic acid prepared in step 1 and mix uniformly at a temperature of 75° C. to obtain the first mixed solution;

[0035] Step 3. Weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com