Preparation method and application of nano-sulfonated polystyrene microspheres

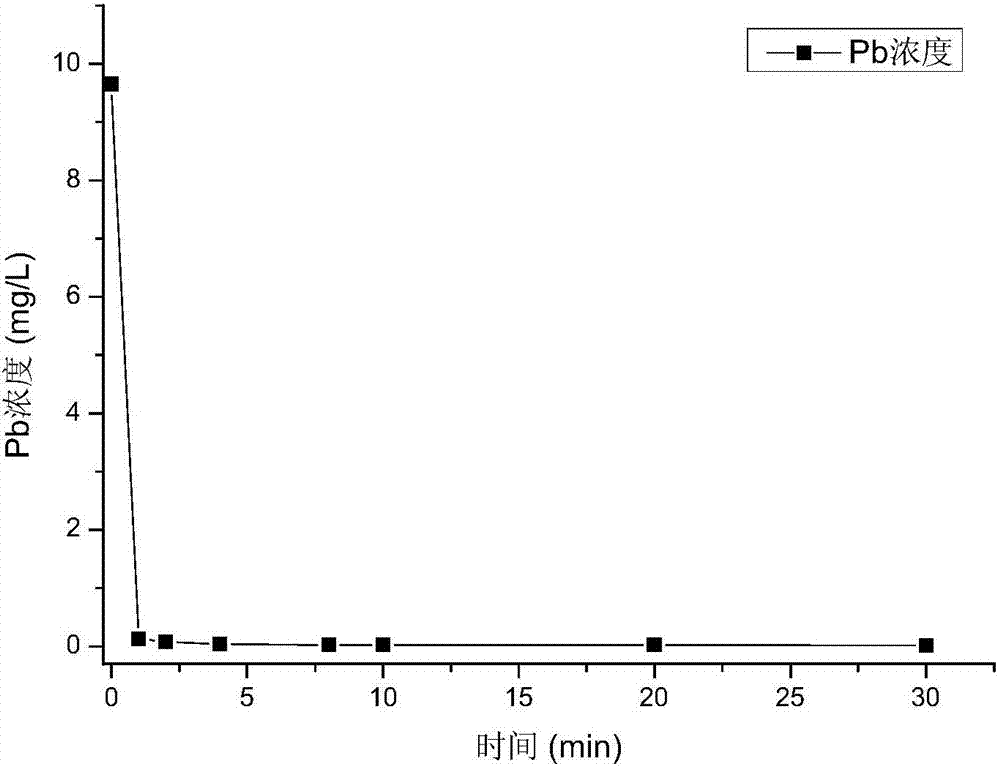

A technology of sulfonated polystyrene and polystyrene microspheres, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of slow adsorption speed, small exchange capacity, limited effect, etc., and achieve processing speed Fast, large capacity, high sulfonation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 0.1g SDS, 0.05g Na 2 CO 3 Dissolve in a three-necked flask filled with 150mL of distilled water, stir, fill with nitrogen for 30min, add 15mL of styrene and raise the temperature to 60°C, stir and mix for 30min. Add 7.5mL of hot solution containing 0.031g of potassium persulfate, mix well, react at 72°C and 300r / min for 20h, wash the solid product with absolute ethanol and water alternately for several times, and dry it in vacuum at 60°C for 12h. The powdered milky white nano-sized polystyrene microspheres were obtained.

[0031] (2) Add PS into concentrated sulfuric acid according to the ratio of PS microspheres to concentrated sulfuric acid: 1:40g / mL, and react for 3 hours at 28°C under magnetic stirring. It was vacuum dried at ℃ for 12 hours to obtain nano-sized sulfonated polystyrene microspheres.

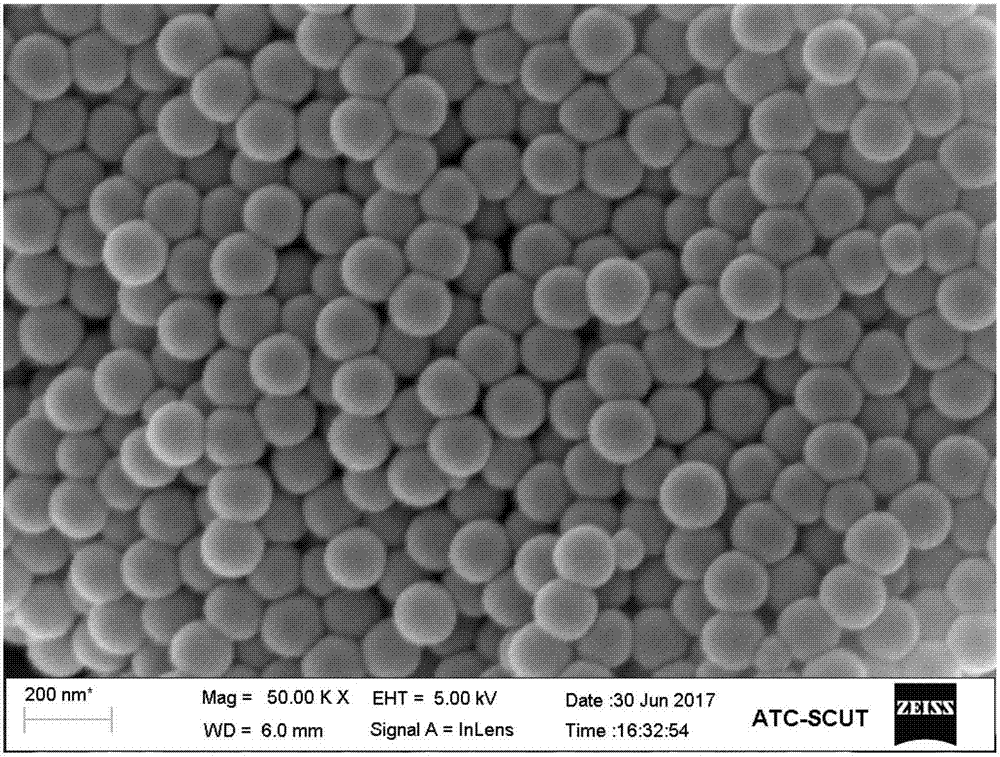

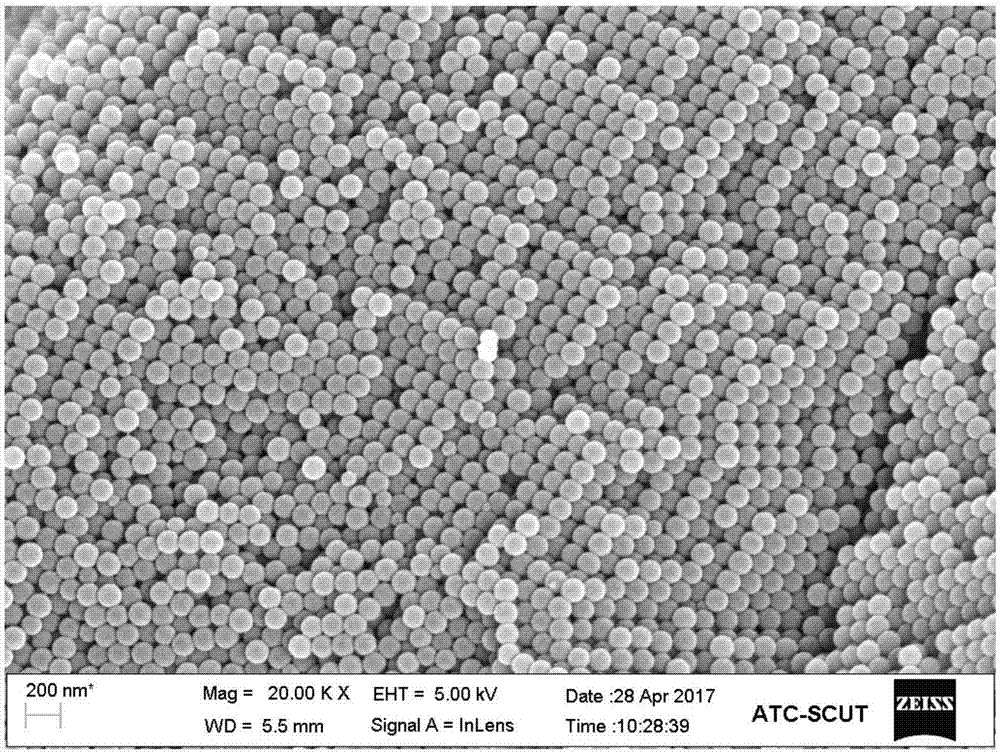

[0032] Gained nanoscale polystyrene microspheres and nanoscale sulfonated polystyrene microspheres were tested by scanning electron microscope respectively, ...

Embodiment 2

[0034] (1) Take 0.15g SDS, 0.05g Na 2 CO 3 Dissolve in a three-necked flask filled with 150mL of distilled water, stir, fill with nitrogen for 30min, add 15mL of styrene and raise the temperature to 60°C, stir and mix for 30min. Add 7.5mL hot solution containing 0.080g potassium persulfate, mix well, react at 72°C and 300r / min for 18h, wash the solid product with absolute ethanol and water alternately for several times, and dry it in vacuum at 60°C for 12h. The powdered milky white nano-sized polystyrene microspheres were obtained.

[0035] (2) Add PS into concentrated sulfuric acid according to the ratio of PS microspheres to concentrated sulfuric acid: 1:30g / mL, and react for 4 hours at 20°C under magnetic stirring. It was vacuum dried at ℃ for 12 hours to obtain nano-sized sulfonated polystyrene microspheres.

Embodiment 3

[0037] (1) Take 0.12g SDS, 0.05g Na 2 CO 3 Dissolve in a three-necked flask filled with 150mL of distilled water, stir, fill with nitrogen for 30min, add 15mL of styrene and raise the temperature to 60°C, stir and mix for 30min. Add 7.5mL hot solution containing 0.080g potassium persulfate, mix well, react at 68°C and 300r / min for 24h, wash the solid product with absolute ethanol and water alternately several times, and dry it in vacuum at 60°C for 12h. The powdered milky white nano-sized polystyrene microspheres were obtained.

[0038] (2) Add PS into concentrated sulfuric acid according to the ratio of PS microspheres to concentrated sulfuric acid: 1:40g / mL, and react for 3 hours at 25°C under magnetic stirring. It was vacuum dried at ℃ for 12 hours to obtain nano-sized sulfonated polystyrene microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com