A p-type double-sided battery packaging adhesive film

A technology for encapsulating film and double-sided cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing component cost, narrow process window, high price, etc., to improve initial power, improve power gain, increase The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

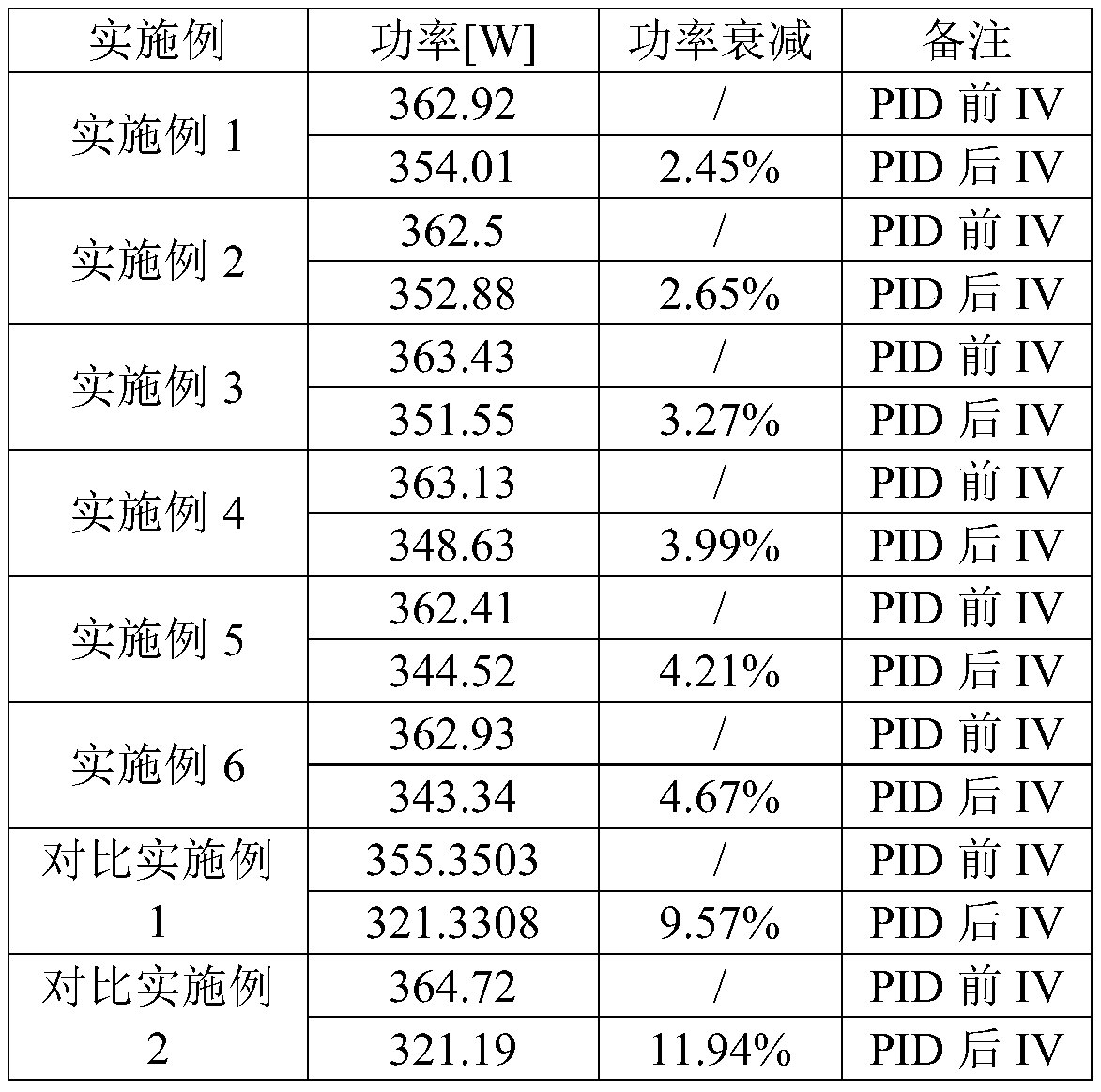

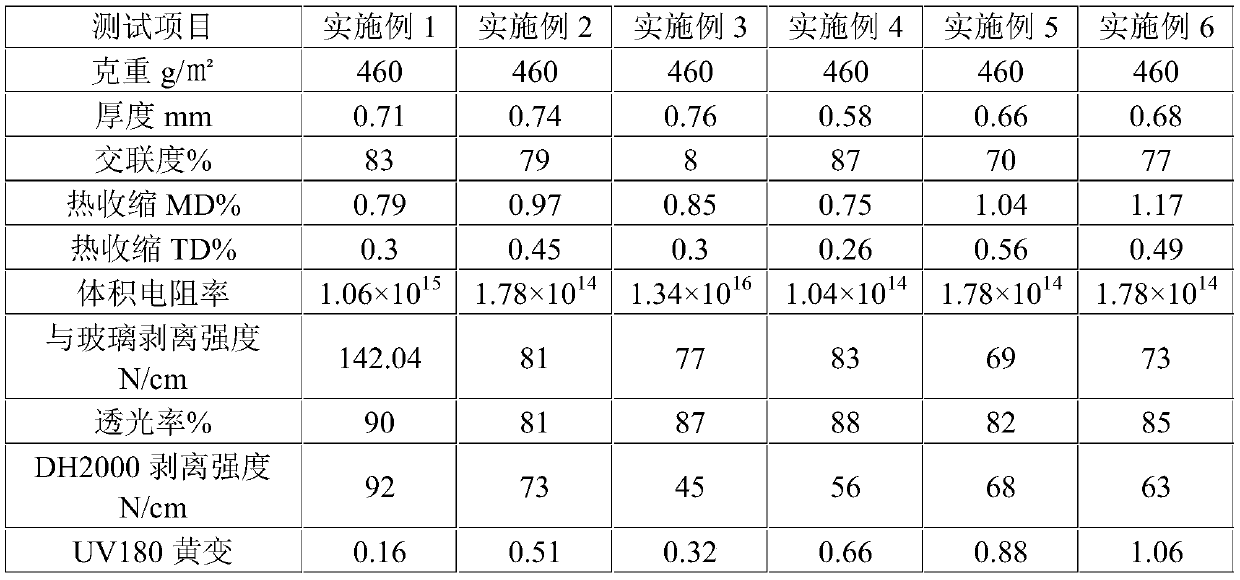

Examples

Embodiment 1

[0044] The P-type double-sided battery encapsulating adhesive film of this embodiment includes PO resin with a melt index range of 5g / 10min, EVA resin with a mass percentage of vinyl acetate (VA) of 25%, 3,5-di-tert-butyl -Dioctadecyl 4-hydroxybenzylphosphonate, 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-tris Oxyzine-2,4,6-(1H,3H,5H)-trione, a mixture of di-n-octyltin dilaurate and polyethylene glycol dilaurate, 2,5-dimethyl-2,5-di-tert Butylperoxyhexane, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate and vinyltriacetoxysilane;

[0045] Among them, the mass percentage of octene in PO resin is 20%, and the light transmittance is > 85%; the light transmittance of EVA resin is > 90%; Film formation, the mass percentage of PO resin in the compound is 10%, and the rest is EVA resin;

[0046] In the encapsulation film, the antioxidant content is 0.4% in terms of mass percentage: the content of the main agent 3,5-di-tert-butyl-4-hydroxybenzyl phosphonic acid dioct...

Embodiment 2

[0052] The P-type double-sided battery encapsulating adhesive film of this embodiment includes PO resin with a melt index range of 18g / 10min, PO resin with a melt index range of 12g / 10min, and vinyl acetate (VA) with a mass percentage of 32%. EVA resin, dioctadecyl-4-tert-butyl-3-hydroxy-2,6-dimethylbenzylphosphonate, 1,3,5-tris(4-tert-butyl-3-hydroxy- 2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione, di-n-octyltin dilaurate and polyethylene glycol di Mixture of laurates, 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, ethyl 3,3-di(tert-butylperoxy)butyrate, 2-hydroxy-4-methyl Oxybenzophenone, Vinyltriacetoxysilane and Vinyltris(β-methoxyethoxy)silane;

[0053] Among them, the mass percentage of octene in PO resin is 25%, and the light transmittance is > 85%; the light transmittance of EVA resin is > 90%; PO resin and EVA resin are compounded, and the compounding method is after blending and doping Extruded into film, the mass percentage of PO resin with a melt index r...

Embodiment 3

[0060] The P-type double-sided battery encapsulating adhesive film of this embodiment includes PO resin with a melt index range of 8g / 10min, PO resin with a melt index range of 15g / 10min, and vinyl acetate (VA) with a mass percentage of 23%. The mass percent composition of EVA resin, vinyl acetate (VA) is the EVA resin of 28%, three (4-nonylphenol) phosphite, three (2,4-di-tert-butylphenyl) phosphite, A mixture of di-n-octyltin dilaurate and polyethylene glycol dilaurate, n-butyl 4,4-bis(tert-amylperoxy)valerate, tert-butyl peroxy 2-ethylhexyl carbonate, 3 , ethyl 3-bis(tert-butylperoxy)butyrate, 2-hydroxy-4-n-octyloxybenzophenone and vinyltris(β-methoxyethoxy)silane;

[0061] Among them, the mass percentage of PO resin octene is 30%, and the light transmittance is > 85%; the light transmittance of EVA resin is > 90%; Go out and form a film, the mass percentage composition of the PO resin that the melt index range is 8g / 10min is 35% in the compound, the mass percentage compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com