Internal combustion engine piston ring assembly

A technology for piston rings, internal combustion engines, applied in the direction of piston rings, pistons, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

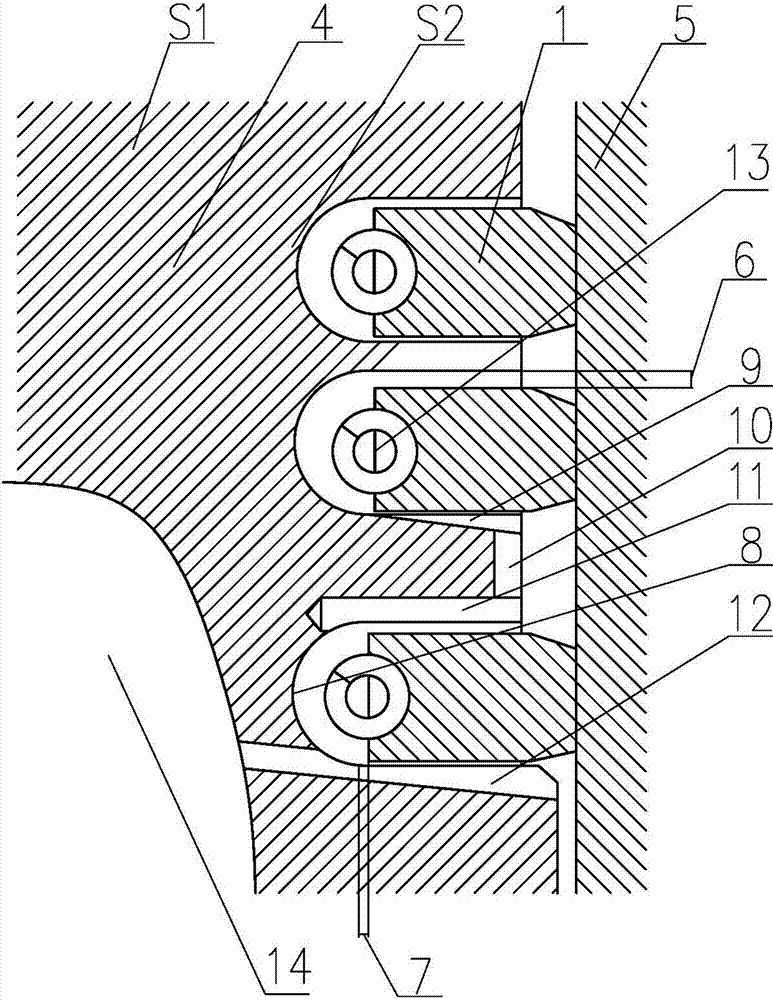

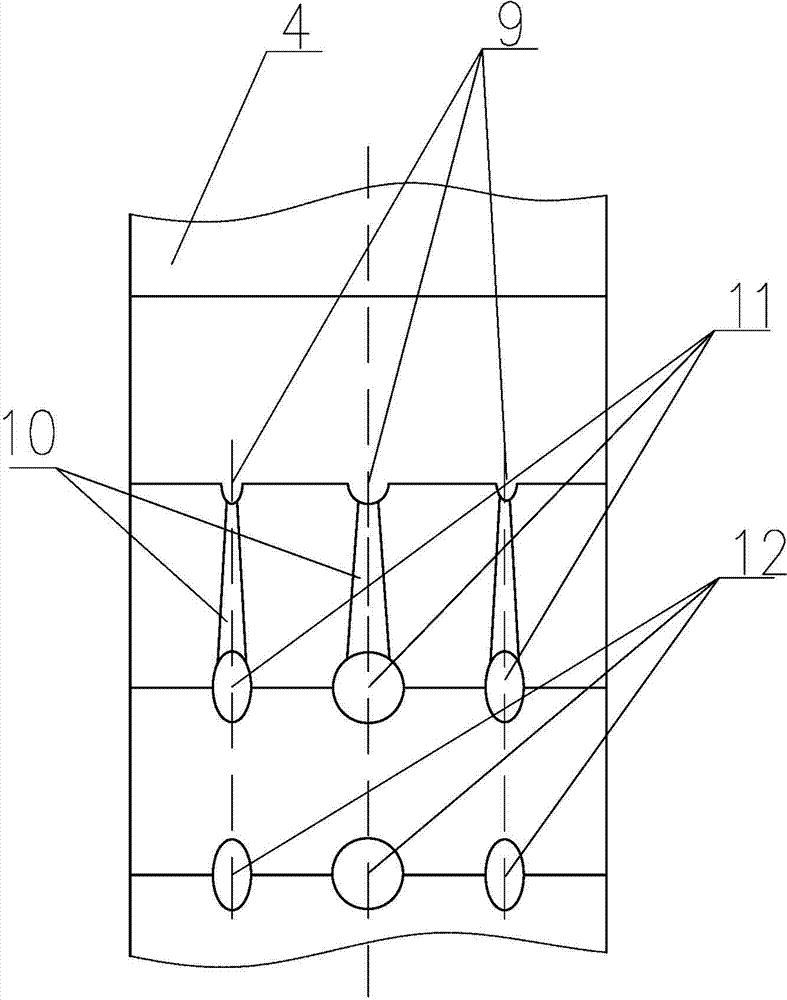

[0026] Depend on figure 1 , figure 2 It can be seen that a piston ring assembly for an internal combustion engine includes a piston ring mounted on the head of the piston 4, the piston head is provided with at least three ring grooves for installing the piston ring, and the piston ring includes a base body 1 made of a metal material. , the assembly side clearance 6 of the second piston ring adjacent to the combustion chamber is 0.15 mm to 0.65 mm.

[0027] The assembly side clearance 6 of the second piston ring of the present invention is preferably 0.35 mm to 0.65 mm.

[0028] The optimal assembly side clearance 6 of the second piston ring of the present invention is 0.35 mm to 0.45 mm.

[0029] In order to further reduce the stress concentration at the bottom 8 of the ring groove of the piston ring, the bottom 8 of the ring groove in the present invention is in the shape of an arc bottom.

[0030] In order to improve the sealing performance of the piston ring, an expansi...

Embodiment 2

[0051] Depend on Figure 4 It can be seen that in order to improve the strength of the piston ring, the surface of the piston ring substrate 1 of the present invention and the contact portion of the piston is provided with a wear-resistant coating 2, and the wear-resistant coating 2 is a tungsten-cobalt alloy deposited by a physical vapor deposition method and a chromium carbide coating. layer; in terms of weight percentage, the weight ratio of tungsten-cobalt alloy is 60% to 80%, the weight ratio of chromium carbide is 20% to 40%, the sum of each component is 100%, and the cobalt element is 25% of the total component. ﹪~45﹪; the thickness of the wear-resistant coating 2 is 10 μm-50 μm, the porosity of the wear-resistant coating 2 is 3%-12%, and the hardness of the wear-resistant coating 2 is 1850-2350 Vickers.

[0052] In order to improve the bonding force between the substrate 1 and the wear-resistant coating 2 and the bearing capacity of the wear-resistant coating, the pist...

Embodiment 3

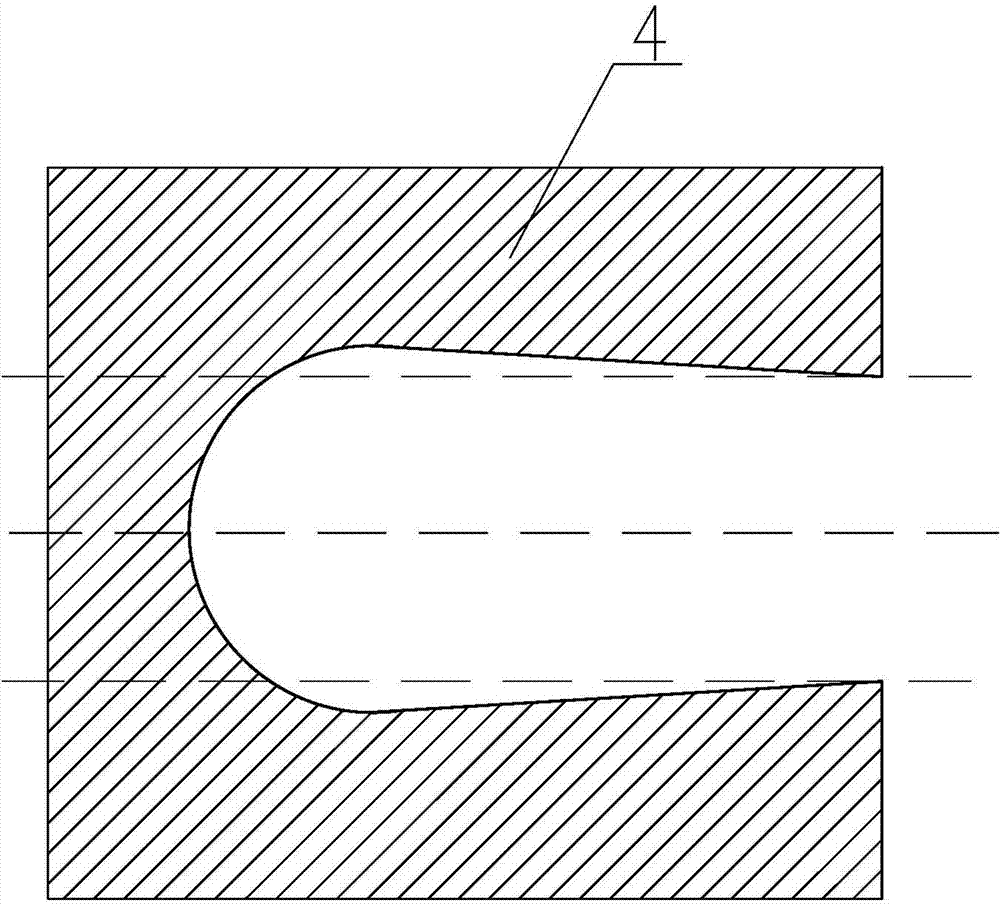

[0069] Depend on Figure 5 It can be seen that the oil return hole 12 under the oil tank in this embodiment is a blind hole, and the lubricating oil scraped off by the piston ring can only flow back into the lubricating system through the gap between the piston and the cylinder, so that impurities in the lubricating oil can be reduced, Improve lubricity.

[0070] Remaining with embodiment 1,2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com