Ag-carbon nano fiber composite material as well as preparation method and application thereof

A carbon nanofiber, composite material technology, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problem of high preparation temperature, complex process, and difficulty in effectively controlling nano-Ag size Ag dispersion To achieve the effect of mild conditions, simple and easy operation, and excellent photocatalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides the preparation method of Ag-carbon nanofiber composite material, is characterized in that, comprises the following steps:

[0040] (1) providing the phosphate mixed solution comprising chlorine source and phosphate and the inorganic silver salt mixed solution comprising chlorine source and inorganic silver salt;

[0041] (2) mixing the phosphate mixed solution and the inorganic silver salt mixed solution, and carrying out a precipitation reaction to obtain a catalyst precursor;

[0042](3) Mixing the catalyst precursor obtained in the step (2) with an organic monosaccharide, a chlorine source and a solvent to obtain a precursor mixed solution, and performing a hydrothermal reaction to obtain an Ag-carbon nanofiber composite material.

[0043] The present invention provides a phosphate mixed solution including a chlorine source and a phosphate and an inorganic silver salt mixed solution including a chlorine source and an inorganic silver salt.

...

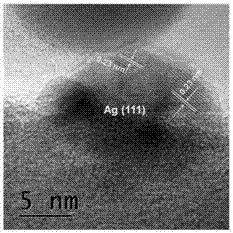

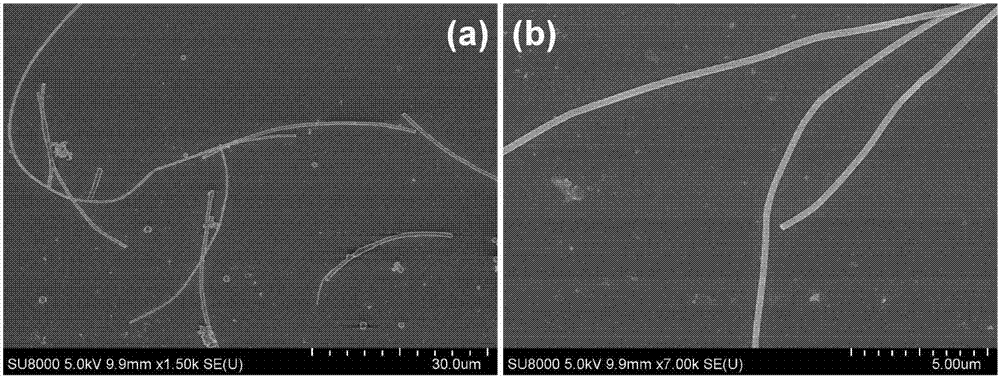

Embodiment 1

[0076] Preparation of catalyst precursor:

[0077] Weigh 17.5mg NaCl and dissolve it in deionized water, transfer to a 1000mL volumetric flask to prepare a 0.3mmol / L NaCl aqueous solution, and set aside.

[0078] 0.2g Na 2 HPO 4 Dissolve in 10mL of the above NaCl aqueous solution; 0.2g AgNO 3 Dissolve in 30 mL of the above NaCl aqueous solution.

[0079] Under 250rpm magnetic stirring, Na 2 HPO 4 The mixed solution was added to the AgNO at a rate of 0.3mL / min 3 In the mixed solution, a yellow precipitate was formed, which was centrifuged and washed to obtain a yellow solid Ag 3 PO 4 -AgCl.

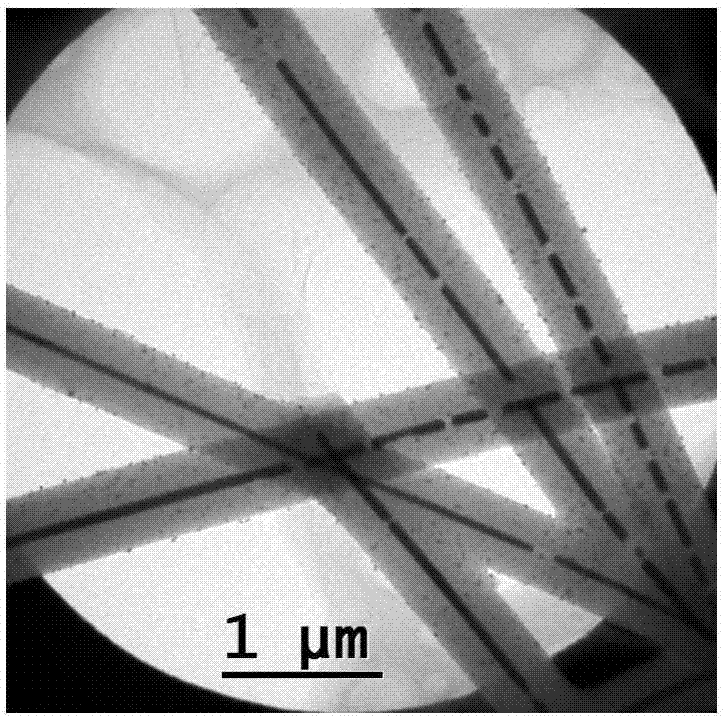

[0080] In situ growth of Ag-carbon nanofibers by hydrothermal reaction:

[0081] Weigh 5.9451g of glucose and dissolve it in 60mL of the aforementioned NaCl aqueous solution, add the aforementioned yellow solid Ag 3 PO 4 -AgCl was ultrasonically dispersed, then transferred to a hydrothermal reactor, and the hydrothermal reactor was kept in an oven at 180°C for 5 hours at a heati...

Embodiment 2

[0084] The Ag-carbon nanofiber composite material prepared in Example 1 was used for photocatalytic degradation of methylene blue solution.

[0085] In the photoreactor, 30 mg of Ag-carbon nanofiber samples were weighed and dispersed in 100 mL of methylene blue solution with a concentration of 50 mg / L. Under dark conditions, methylene blue was adsorbed on the photocatalyst for 2 h to achieve adsorption-desorption equilibrium, and every 20 min Take out 3mL of liquid and centrifuge to separate the catalyst, then carry out the UV-Vis absorption spectrum test. Then, the photoreactor was irradiated with visible light with a wavelength greater than 400nm for 2 hours for photocatalytic reaction, and 3 mL of liquid was taken out every 15 minutes and centrifuged to separate the catalyst for UV-Vis absorption spectrum test to determine the concentration change of methylene blue with the reaction time.

[0086] Under the same conditions, the Ag photocatalyst without carbon nanofibers was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com