Preparation method of cellulose/nano cerium oxide composite membrane

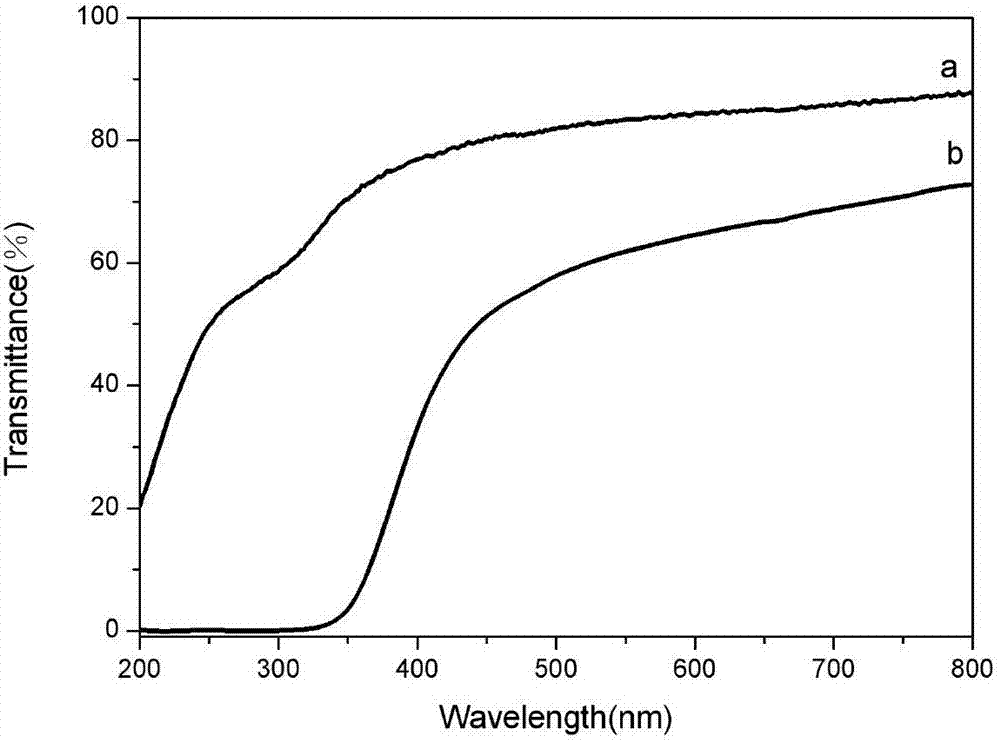

A technology of nano-cerium oxide and cellulose film, which is applied in the field of preparation of cellulose/nano-cerium oxide composite film, to achieve the effect of simple and feasible preparation, good transparency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of cellulose film: disperse the cotton linters in the alkaline solution, freeze the resulting cellulose suspension at low temperature, take it out after 24 hours, stir it with high-speed machinery, and centrifuge. The cellulose solution obtained by this simple method is placed in a glass Push the plate to make a thin layer, then immerse in concentrated sulfuric acid solution to solidify and regenerate to obtain a transparent cellulose film, and the cellulose film is repeatedly washed with deionized water and freeze-dried for later use;

[0024] (2) Soak the cellulose membrane in Ce at a concentration of 0.8mol / L at room temperature 3+ solution for 10 h, followed by repeated washing with deionized water to remove unadsorbed Ce 3+ ion;

[0025] (4) Then at room temperature, the cellulose film is immersed in a NaOH solution with a concentration of 10mol / L to react;

[0026] (5) The cellulose membrane obtained by the reaction is taken out, rinsed repeatedl...

Embodiment 2

[0029] (1) Preparation of cellulose film: Add bacterial cellulose to 200mL LiCl / DMAc dissolution system at room temperature, then heat and stir in an oil bath, react for a period of time, and then cool at room temperature. After the bacterial cellulose is completely dissolved, the air bubbles are removed by centrifugation, the obtained bacterial cellulose solution is cast in a mold, left at room temperature for 24 hours to form a film, and the obtained bacterial cellulose film is washed with deionized water and freeze-dried;

[0030] (2) Soak the cellulose membrane in Ce at a concentration of 0.5mol / L at room temperature 3+ 10h in the solution;

[0031] (3) Then wash repeatedly with deionized water to remove unadsorbed Ce 3+ ion;

[0032] (4) Then at room temperature, the cellulose film is immersed in a NaOH solution with a concentration of 10mol / L to react;

[0033] (5) The cellulose membrane obtained by the reaction is taken out, rinsed repeatedly with deionized water, an...

Embodiment 3

[0036] (1) Preparation of cellulose film: disperse the cotton linters in the alkaline solution, freeze the resulting cellulose suspension at low temperature, take it out after 24 hours, stir it with high-speed machinery, and centrifuge. The cellulose solution obtained by this simple method is placed in a glass Push the plate to make a thin layer, then immerse in concentrated sulfuric acid solution to solidify and regenerate to obtain a transparent cellulose film, and the cellulose film is repeatedly washed with deionized water and freeze-dried for later use;

[0037] (2) Soak the cellulose membrane in Ce at a concentration of 0.5mol / L at room temperature 3+ 10h in the solution;

[0038] (3) Then wash repeatedly with deionized water to remove unadsorbed Ce 3+ ion;

[0039] (4) Then at room temperature, the cellulose film is immersed in an ammonia solution with a concentration of 20mol / L to react;

[0040] (5) The cellulose membrane obtained by the reaction is taken out, rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com