Carbon fiber composite artificial bone and its preparation method

A composite material and carbon fiber technology, applied in the field of artificial bone, to achieve strong designability, enhanced deformation recovery ability, and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

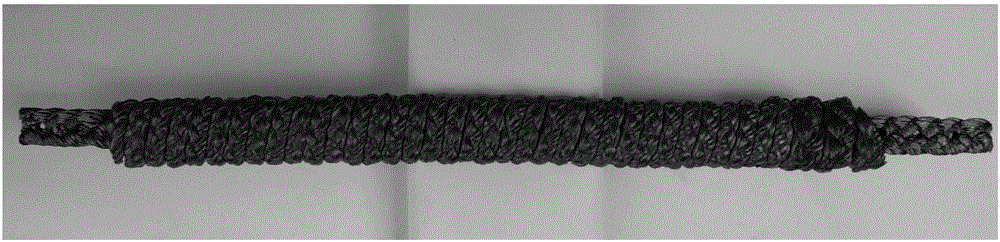

[0051] 1) First twist the 12k polyacrylonitrile-based carbon fiber into a carbon fiber rope, and then weave three 12k carbon fiber ropes into a carbon fiber braid, and the carbon fiber braid is tightly wound in a D-shaped cross-section in a clockwise direction (the size of the cross-section is the same as that of a human rib). The same) carbon material mold to form a spring-like carbon fiber prefabricated body.

[0052] 2) The tubular carbon fiber preform is placed in a natural gas atmosphere, and chemical vapor deposition is carried out at a temperature of 1100°C for 200 hours, and the density of the green body is 1.2g / cm 3 , to obtain the carbon fiber spring-like skeleton body;

[0053] 3) After the carbon fiber spring-shaped skeleton body is removed from the rod-shaped mold, it is placed in an argon protective atmosphere, heated to 2200° C., and the holding time is 10 hours for purification treatment to obtain a carbon fiber spring-shaped skeleton;

[0054] 4) The carbon f...

Embodiment 2

[0058] 1) Twist 12k polyacrylonitrile-based carbon fiber and 6k polyacrylonitrile-based carbon fiber into carbon fiber ropes respectively, one 12k polyacrylonitrile-based carbon fiber rope and two 6k polyacrylonitrile-based carbon fiber ropes are woven into carbon fiber braids, and the two Carbon fiber braids are tightly wound clockwise on a carbon material mold with a rectangular cross-section (the size of the cross-section is similar to that of a human rib), forming a spring-like carbon fiber prefabricated body.

[0059] 2) The carbon fiber spring-like carbon fiber prefabricated body uses phenolic resin as the impregnating agent, and undergoes densification processes such as vacuum pressure impregnation, curing treatment, and carbonization. The main parameters are: impregnation pressure 3.0MPa, time 5 hours; curing at 200°C for 20 hours; carbonization at normal pressure for 4 hours at 1000°C. After 3 cycles, the green body density is 1.5g / cm 3 ; That is, the carbon fiber sp...

Embodiment 3

[0065] 1) First twist three 3k polyacrylonitrile-based carbon fibers into carbon fiber ropes, then weave five carbon fiber ropes into carbon fiber braids, and wind the three carbon fiber braids counterclockwise in parallel and tightly on a carbon material mold with a rectangular cross-section (cross-section about the size of a human rib), forming a spring-like carbon fiber prefab.

[0066] 2) The tubular carbon fiber prefabricated body first uses propylene as a carbon source and nitrogen as a dilution gas, and conducts chemical vapor deposition at a temperature of 900° C. for 120 hours. Then use phenolic resin as impregnant, after vacuum pressure impregnation, curing treatment, carbonization and other densification processes, the main parameters are: impregnation pressure 4.0MPa, time 3 hours; curing at 220°C for 15 hours; temperature at 950°C , normal pressure carbonization for 6 hours, liquid phase impregnation for 2 cycles, and the density of the prepared green body is 1.8g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com