Method for extracting HA (hyaluronic acid) from tuna eyes

A technology for hyaluronic acid and tuna, which is applied in the field of extracting hyaluronic acid from tuna eyes, can solve the problems of complicated operation and high production process cost, and achieve the effects of high purity, reduced production cost and small loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

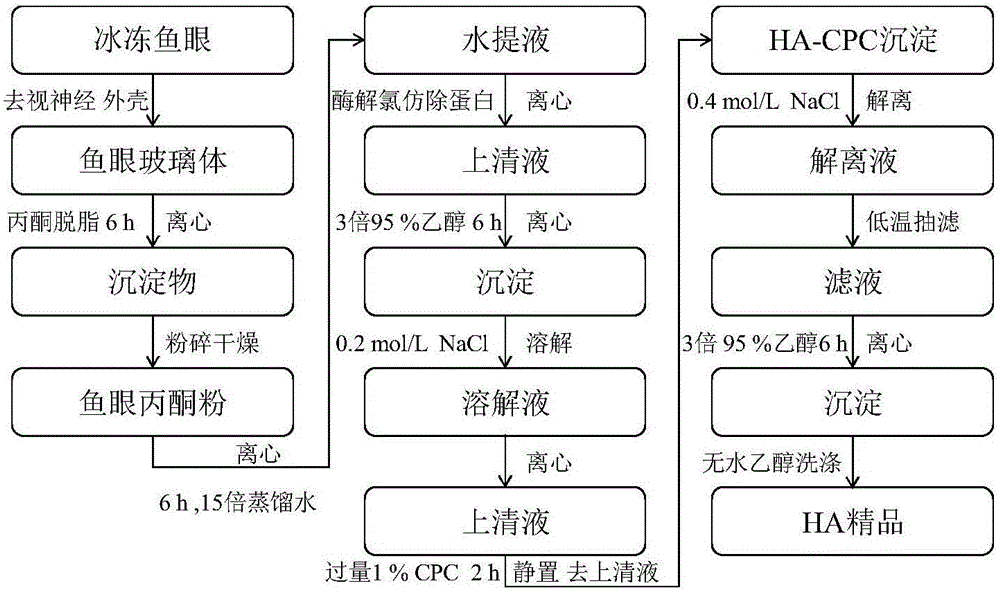

[0022] Embodiment 1: tuna eye pretreatment prepares fish eye powder

[0023] Take 4314g of frozen fresh fish eye, after thawing at normal temperature, remove the shell, fish tissue, optic nerve, etc., and keep the black fish eye vitreous body, which weighs 1431g. During the operation, the liquid in the vitreous is easy to flow out and should be recovered as much as possible. Cut the black glass into pieces, add 3 times the volume of acetone, and stir at room temperature for 6 h. Then centrifuge at 10,000 rpm at 4°C, take the precipitate and dry it in a vacuum oven at 45°C for 10 hours, and take out and turn over the product from time to time. After the precipitate was dried, it was pulverized and then dried in a vacuum oven at 45°C for 10 hours. The obtained powder was 210g of fish eye powder, which could be used as a raw material for extracting hyaluronic acid, and could also be stored at -20°C for a long time.

Embodiment 2

[0024] Embodiment 2: tuna eye pretreatment prepares fish eye powder

[0025] Take 2932 g of frozen fresh fish eyes, after thawing at normal temperature, remove the shell, fish tissue, optic nerve, etc., and keep the black fish eye vitreous body, which weighs 941 g. During the operation, the liquid in the vitreous is easy to flow out and should be recovered as much as possible. Cut the black glass into pieces, add 3 times the volume of acetone, and stir at room temperature for 4 h. Then centrifuge at 10,000 rpm at 4°C, take the precipitate and dry it in a vacuum oven at 30°C for 6 hours, and take out and turn over the product from time to time. After the precipitate was dried, it was crushed and then dried in a vacuum oven at 30°C for 6 hours. The obtained powder was 154g of fish eye powder, which could be used as a raw material for extracting hyaluronic acid, and could also be stored at -20°C for a long time.

Embodiment 3

[0026] Example 3: Enzymatic Extraction of Fisheye Hyaluronic Acid

[0027] The fish eye powder obtained by the method of Example 1 is used as a raw material, and the process of extracting hyaluronic acid by enzymatic hydrolysis is as follows

[0028] (1) Weigh 25g of fish eye powder, add 500mL of deionized water, and stir at room temperature for 6h.

[0029] (2) Centrifuge the reaction solution of (1), take the supernatant and add 500U trypsin / g fish eye powder, and react at 40°C and pH 8.5 for 120min.

[0030] (3) After inactivating the reaction solution of (2) in a 90°C water bath, cool it down. Then centrifuge at 10000 rpm at 4°C to obtain supernatant.

[0031] (4) Put 500mL of the supernatant in (3) into the separatory funnel, then add 200mL of chloroform, 50mL of n-butanol, stir vigorously for 20min, and put it in the separatory funnel for stratification (divided into upper, middle and lower layers) , release the lower layer of chloroform and the middle layer of protei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com