Composition for solid precipitation and inhibition of oil and gas well

A facies deposition and composition technology, which is applied in the field of solid deposition inhibiting compositions, can solve the problems of inability to produce oil and gas in oil and gas wells, reduction of formation permeability in near-wellbore zones, pump stuck, tubing blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

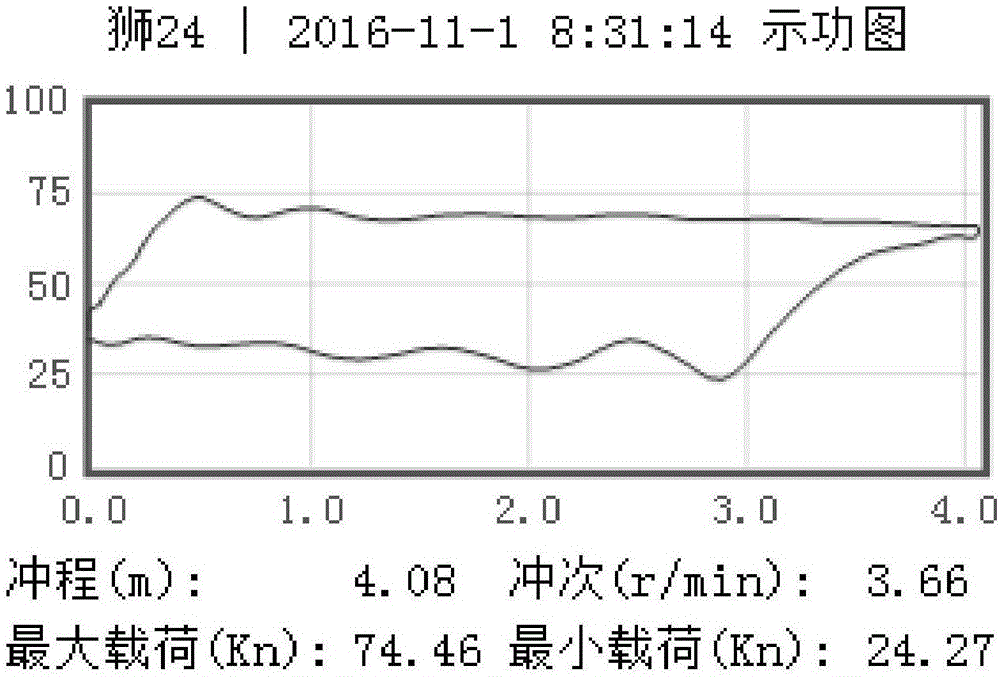

[0041] The water sample is supersaturated formation water from Well Shi 24 in Shizigou, Qaidam Basin, Qinghai. The first group: add 0.08g, 0.09g, 0.1g, 0.11g, 0.12g and 0.13g of sub-groups with mass fractions of 0.08%, 0.09%, 0.1%, 0.11%, 0.12% and 0.13% to 100g water sample respectively Potassium ferricyanide solution, set up two parallel samples. The second group: add 0.08g, 0.09g, 0.1g, 0.11g, 0.12g and 0.13g of 0.08%, 0.09%, 0.1%, 0.11%, 0.12% and 0.13% sub- Sodium ferricyanide solution, set up two parallel samples. Take the supersaturated formation water with added water as the control, place them in a constant temperature oven at 100°C for 1 hour, and then filter them separately to obtain the quality difference after filtration respectively. The ratio is used as the inhibition rate of sodium ferrocyanide or potassium ferrocyanide to the precipitation of inorganic salts in supersaturated formation water. The results are shown in Table 1:

[0042] Inhibition performanc...

Embodiment 2

[0047] This example provides a method for preparing a copolymer of acrylamide, dimethylaminoethyl methacrylate and acyloxyethyltrimethylammonium chloride by using an inverse microemulsion polymerization method. The method is as follows:

[0048] 7% acrylamide (AM), 2% hydrophobic monomer dimethylaminoethyl methacrylate (DMAEMA), 3% cationic monomer methacrylateoxyethyltrimethylammonium chloride (DMC) and 78% of Add 0.02% potassium persulfate and sodium bisulfite under water and nitrogen as initiators, wherein the mass ratio of potassium persulfate to sodium bisulfite is 1:2, and stir the reaction for 6 hours at 50-60°C, that is A copolymer of acrylamide, dimethylaminoethyl methacrylate and acyloxyethyltrimethylammonium chloride was obtained.

Embodiment 3

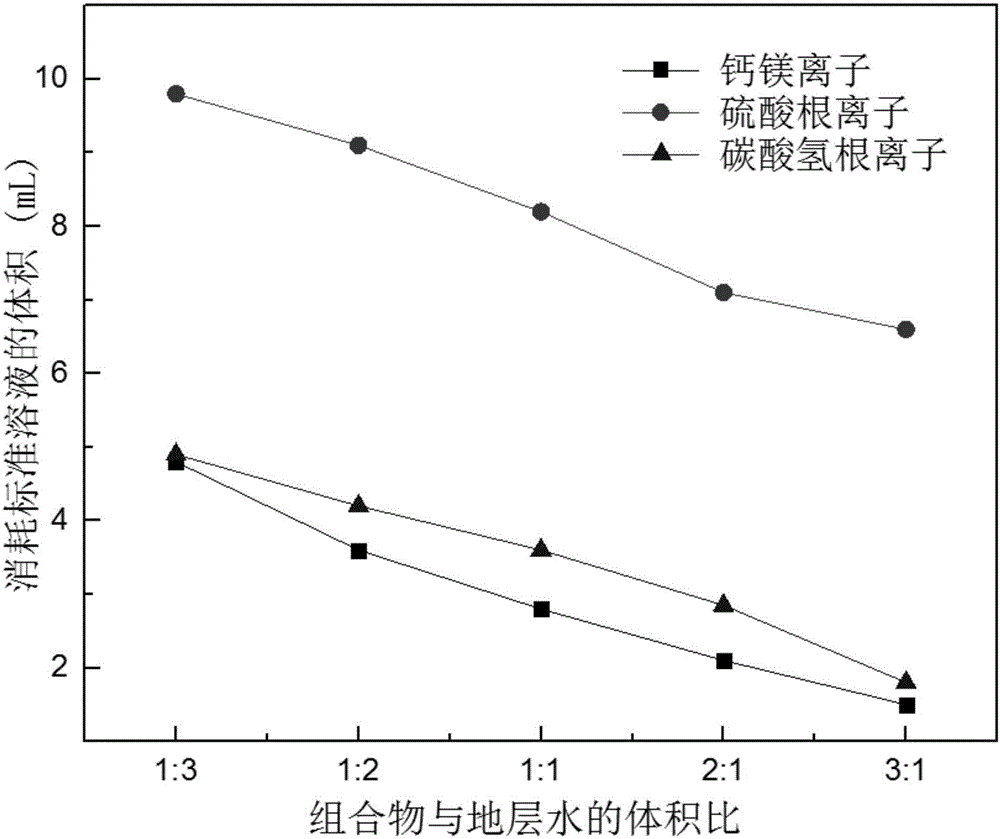

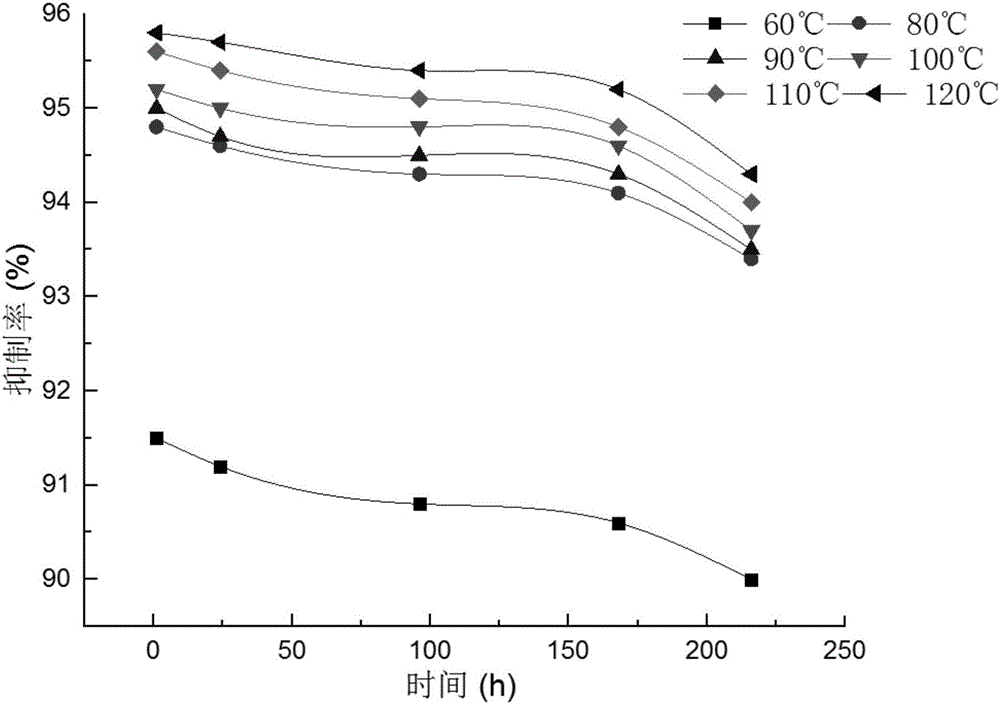

[0050] The water sample is supersaturated formation water from Well Shi 24. The solid-phase deposition inhibition composition is a copolymer comprising acrylamide prepared in Example 2, dimethylaminoethyl methacrylate and acyloxyethyl trimethylammonium methacrylate, and sodium ferrocyanide. solution. Wherein the mass fraction of sodium ferrocyanide in the composition for inhibiting solid phase deposition is 0.1%, the copolymer of acrylamide, dimethylaminoethyl methacrylate and acyloxyethyl trimethyl ammonium chloride The mass fractions in the composition for inhibiting solid phase deposition are 0.005%, 0.01%, 0.015% and 0.02%, respectively.

[0051] Add 0.105g, 0.11g, 0.115g, and 0.12g of the composition for inhibiting solid phase deposition to 100g of supersaturated formation water, and take the supersaturated formation water with 100g of water as a contrast to measure the effect of the composition for inhibiting solid phase deposition on the solid phase Deposition inhibit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

| anti-fouling rate | aaaaa | aaaaa |

| anti-fouling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com