Preparation and application of molecular-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster base

A low-temperature magnetic refrigeration, molecular-based technology, applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of long-term solvothermal reaction or heating reflux reaction, high energy consumption of the method, and achieve convenient operation. , good repeatability, simple raw material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, 0.3mmol GdCl 3 ·6H 2 O, 0.8 mmol CoCl 2 ·6H 2 O, 1.7 mmol of organic ligand diethanolamine was placed in a round-bottomed flask, and 10 mL of organic solvent methanol was added, and after magnetic stirring for 10 minutes, 1 mmol of sodium methoxide was added, and stirring was continued for 6 hours. The resulting mixed solution was filtered, the filtrate was placed in a beaker, covered with a perforated plastic wrap, and left to volatilize naturally at room temperature for 5 days to obtain blocky black crystals with good crystallinity, which were washed with methanol, Suction filtration, and dry at room temperature, prepare the molecule-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster group, productive rate 55% (with GdCl 3 ·6H 2 O meter).

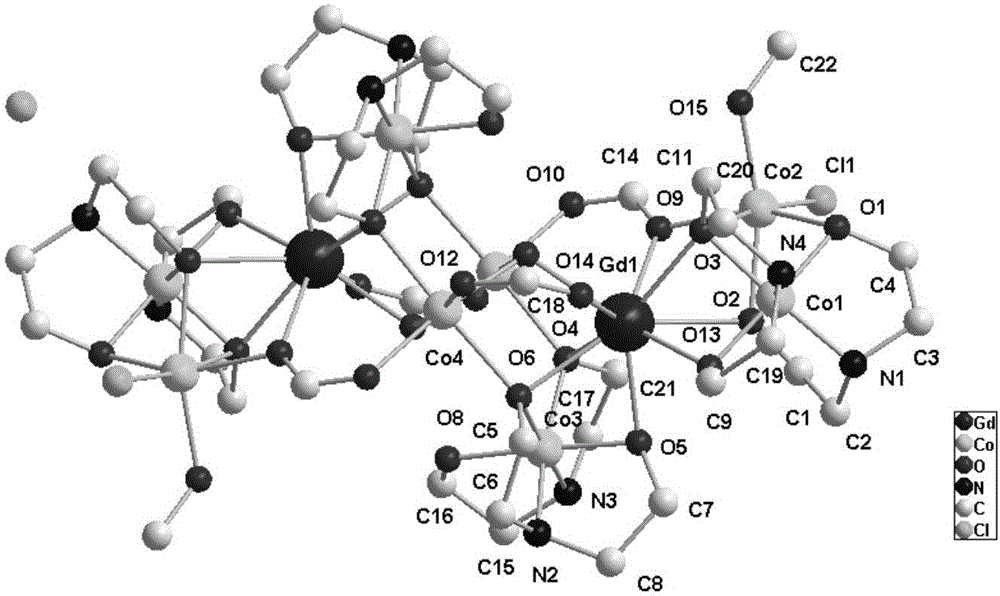

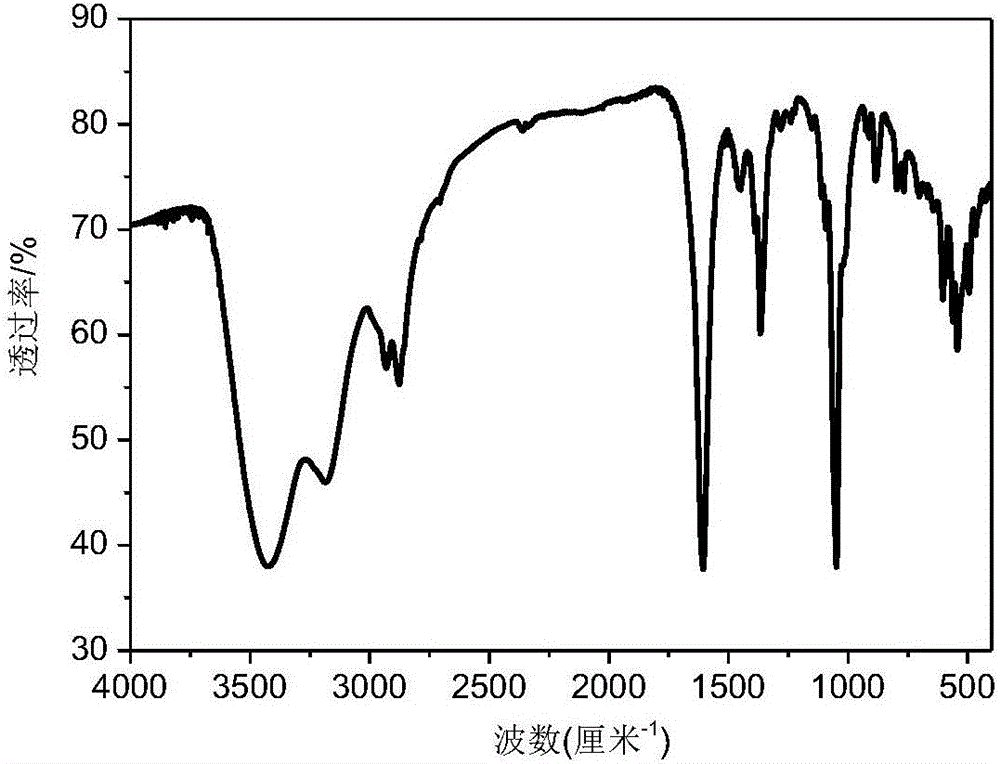

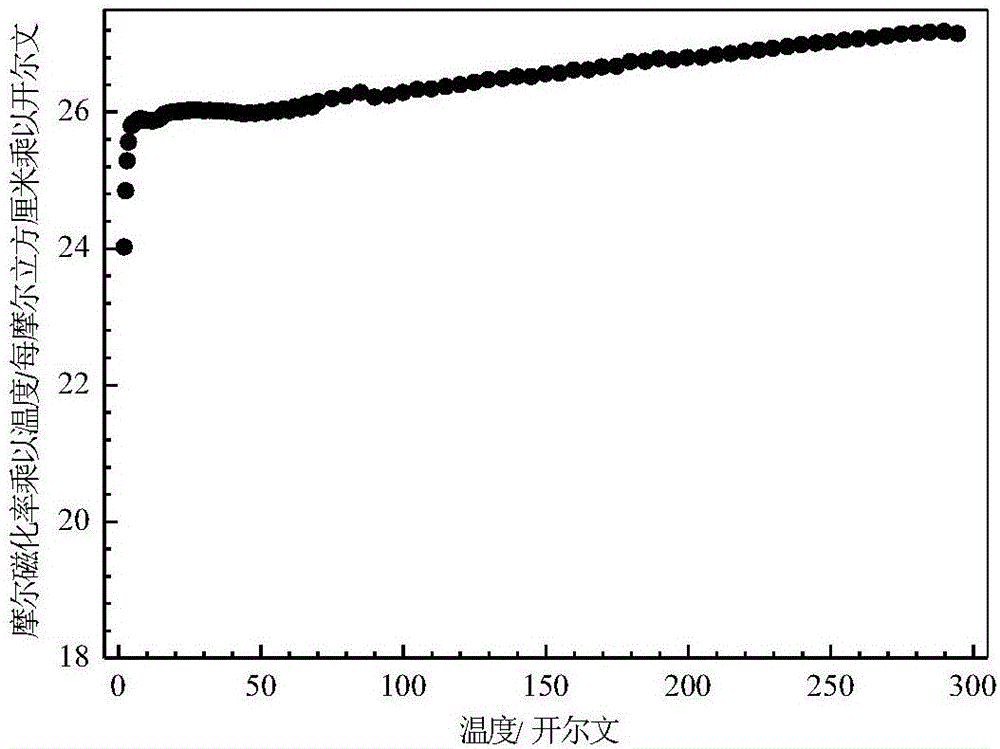

[0033] Analysis of the single crystal diffraction data of the prepared black block crystals in this example shows that the molecular formula of the complex is [Co 8 Gd 2 (L...

Embodiment 2

[0037] In this embodiment, 0.3mmol GdCl 3 ·6H 2 O, 1 mmol CoCl 2 ·6H 2 O, 2mmol of organic ligand diethanolamine was placed in a round bottom flask, 15mL of organic solvent methanol was added, and after magnetic stirring for 10 minutes, 1.2mmol of sodium methoxide was added, and stirring was continued for 8 hours. The resulting mixed solution was filtered, the filtrate was placed in a beaker, covered with a perforated plastic wrap, and allowed to stand at room temperature for natural volatilization for 6 days to obtain blocky black crystals with good crystallinity. The obtained blocky black crystals were washed with methanol, Suction filtration, and dry at room temperature, prepare the molecule-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster group, productive rate 56% (with GdCl 3 ·6H 2 O meter). The various characterizations and results of the target product obtained are the same as in Example 1.

Embodiment 3

[0039] In this embodiment, 0.4mmol GdCl 3 ·6H 2 O, 1.2 mmol CoCl 2 ·6H 2 O, 2.3 mmol of organic ligand diethanolamine was placed in a round-bottomed flask, 20 mL of organic solvent methanol was added, and after magnetic stirring for 10 minutes, 1.5 mmol of sodium methoxide was added, and stirring was continued for 10 hours. The resulting mixed solution was filtered, the filtrate was placed in a beaker, covered with a perforated plastic wrap, and allowed to stand at room temperature for natural volatilization for 7 days to obtain blocky black crystals with good crystallinity. The obtained blocky black crystals were washed with methanol, Suction filtration, and dry at room temperature, prepare the molecule-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster group, productive rate 58% (with GdCl 3 ·6H 2 O meter). The various characterizations and results of the target product obtained are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com