Blade of disc shearing machine and preparing method thereof

A disc shearing and blade technology, which is applied in the direction of shearing devices, knives for shearing machine devices, manufacturing tools, etc., can solve the lack of comprehensive performance of wear resistance and toughness, the inability to meet the requirements of processing accuracy, alloy materials High cost and other issues, to achieve good interface bonding, improve shear efficiency, and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Below, combine Figure 1-4 , the method for preparing the disc shear blade of the present invention and the prepared blade are described in detail. Wherein, the preparation method of disc shear blade comprises the following steps:

[0035] Step S1, preparing a blade base body according to the design requirements, and coating the blade base body with a blade sheath.

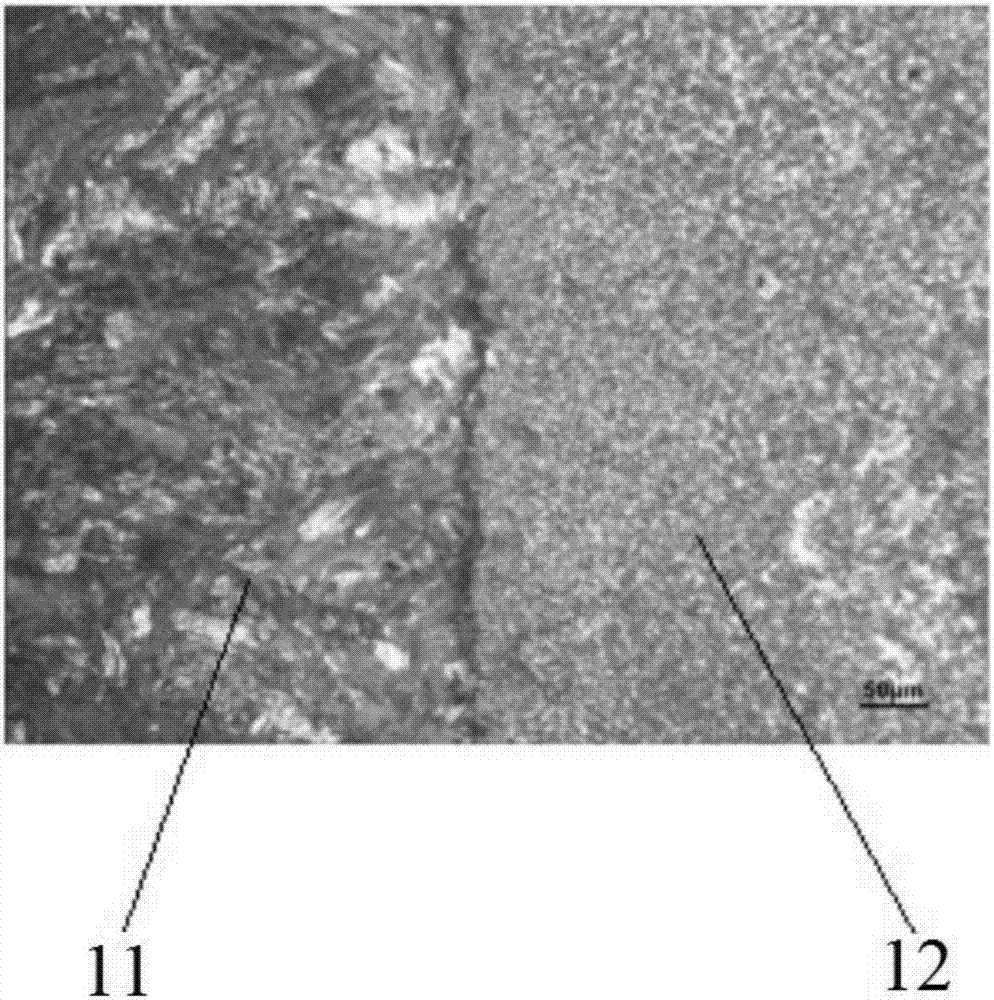

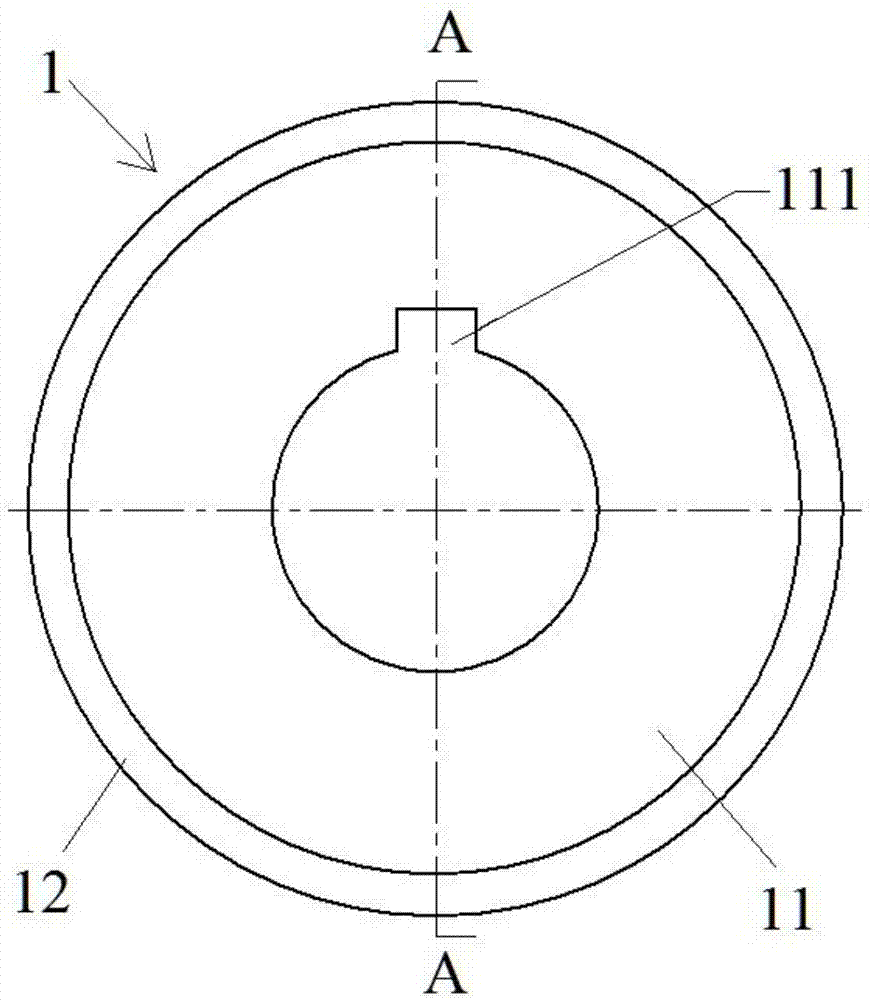

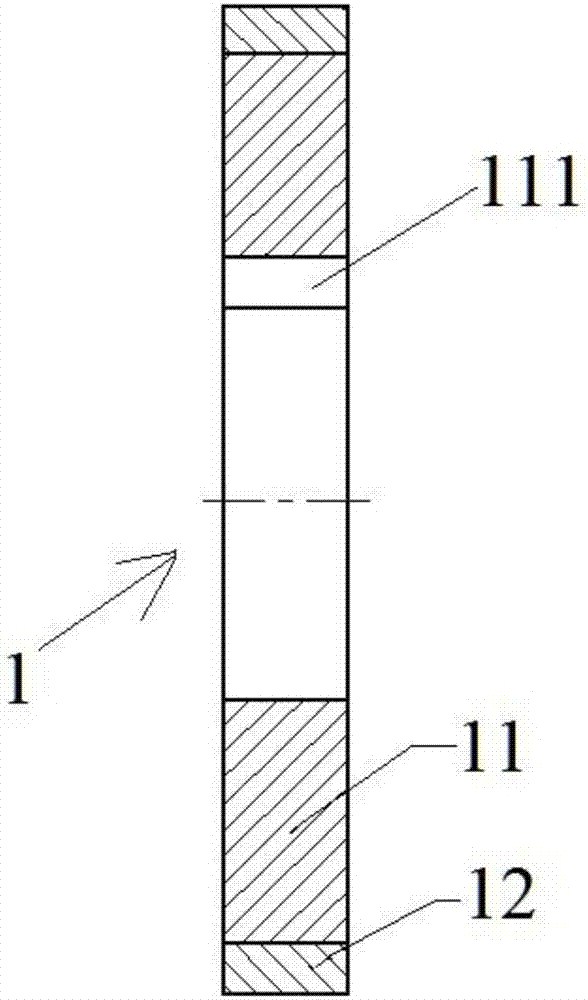

[0036] like figure 1 and 2As shown, the blade 1 comprises a blade base 11 and a blade layer 12 . Wherein, the blade base 11 is an annular cake body, and the inner side wall of the annular cake body is provided with an assembly keyway 111 for installation and positioning; the blade layer 12 fits and covers the outer side wall of the blade base body 11 . Preferably, the base body 11 of the blade can be made of 35CrMo steel, so that the prepared blade can withstand impact, bending and high load under complex force conditions, thereby prolonging the service life of the blade.

[0037] like image 3 As sho...

Embodiment 1

[0047] Prepare a blade base body 11 with an outer diameter of 300 mm, and coat the blade base body 11 with a blade sheath 2, and the powder particle size of the alloy powder 3 filled into the blade sheath 2 is 50 μm, and the chemical composition and each chemical composition The weight percentages are: 2.1% carbon, 5.0% chromium, 1.5% molybdenum, 10.0% vanadium, 0.8% silicon, 0.5% manganese, and the rest is Fe. After the filling of the alloy powder 3 is completed, the alloy powder 3 is firstly vibrated, and the top cover 26 is placed on the top of the powder filling channel 25, and sealed and connected by argon arc welding. Next, place the blade cover 2 with the blade matrix 11 and the alloy powder 3 built in it in a degassing furnace to heat and vacuumize it. When the temperature reaches 450° C. and the vacuum degree reaches 2×10 -3 Pa, keep the temperature and vacuum constant for 2 hours to complete the degassing and heat preservation treatment. Then, put the blade sheath 2...

Embodiment 2

[0050] Prepare a blade base body 11 with an outer diameter of 400mm, and coat the blade base body 11 with a blade sheath 2, and the powder particle size of the alloy powder 3 filled into the blade sheath 2 is 100 μm, and the chemical composition and each chemical composition The weight percentages are: 2.2% carbon, 4.5% chromium, 1.2% molybdenum, 9.0% vanadium, 1.0% silicon, 0.8% manganese, and the rest is Fe. After the filling of the alloy powder 3 is completed, the alloy powder 3 is firstly vibrated, and the top cover 26 is placed on the top of the powder filling channel 25, and sealed and connected by argon arc welding. Next, place the blade cover 2 with the blade matrix 11 and the alloy powder 3 built in it in a degassing furnace to heat and vacuumize it. When the temperature reaches 500°C and the vacuum degree reaches 2×10 -3 At Pa, keep the temperature and vacuum constant for 4 hours to complete the degassing and heat preservation treatment. Then, put the blade sheath 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com