Preparation method of high-strength, high-toughness, high-conductivity single-walled carbon nanotube fibers

A single-walled carbon nanotube, high toughness technology, applied in the processing and application of nanomaterials, can solve problems such as poor mechanical properties, electrical conductivity and toughness, and achieve the effects of improving mechanical properties, good electrical conductivity, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

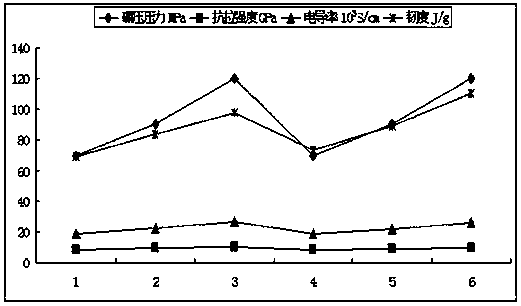

Examples

Embodiment 1

[0029] The CVD preparation method of different single-walled carbon nanotube films: adopt the box-type furnace with constant temperature zone length at 200mm, utilize hydrogen-argon mixed gas (90% argon, 10% hydrogen) as catalytic gas, utilize xylene as carbon source ( 100ml), use ferrocene (25-30g) and elemental sulfur (0.5-1g) as catalysts, set the reaction temperature to 1150-1250°C, control the growth time to 1h, and can prepare single-walled carbon nanometers with a uniform thickness of 1mm tube film. By changing the growth time, the thickness of the single-walled carbon nanotube film can be changed.

Embodiment 2

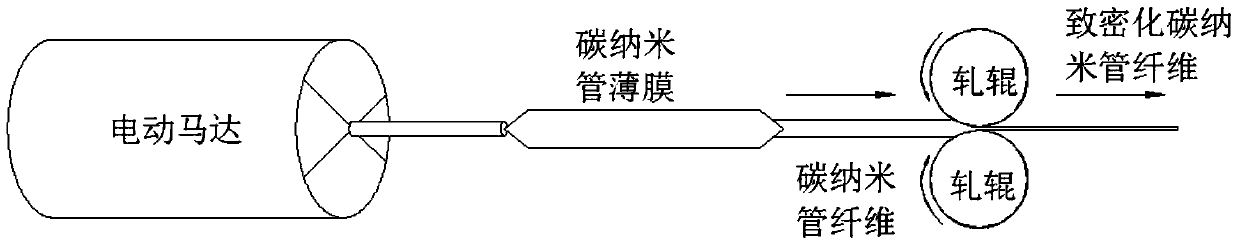

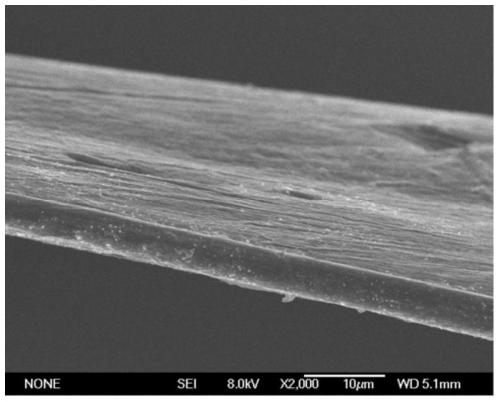

[0031] The single-walled carbon nanotube film with a thickness of 1 mm obtained in Example 1 is fixed horizontally, one end is fixed on the electric motor, and the other end is fixed on a weight with a weight of 50 g, the electric motor is started, and the electric motor drives the single-walled carbon nanotube film. The carbon nanotube film is rotated and spun into cylindrical fibers to obtain single-walled carbon nanotube fibers with a diameter of about 200 μm.

Embodiment 3

[0033] The single-walled carbon nanotube film with a thickness of 1 mm obtained in Example 1 is fixed horizontally, one end is fixed on the electric motor, and the other end is fixed on a weight with a weight of 100 g, the electric motor is started, and the electric motor drives the single-walled carbon nanotube film. The carbon nanotube film was spun and spun into cylindrical fibers to obtain single-walled carbon nanotube fibers with a diameter of about 190 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com