Carbon nano rod composite material and preparation method and application thereof

A technology of carbon nanorods and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low active material content, poor electrochemical performance, large fiber diameter, etc., to achieve Effects of high active material content, improved electrochemical performance, and small nanorod diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

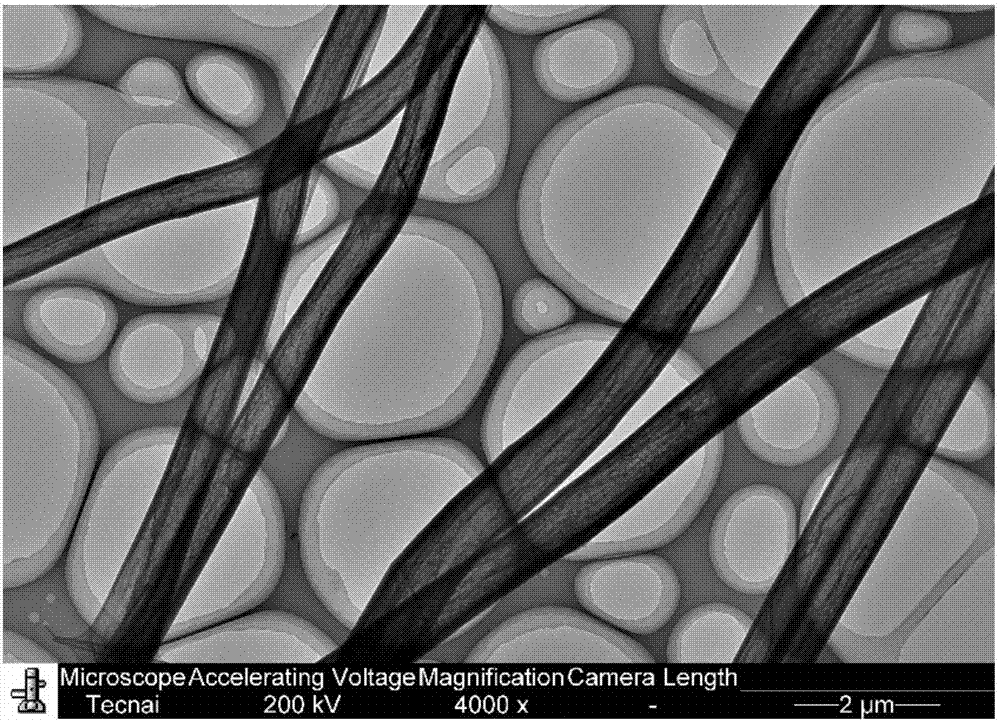

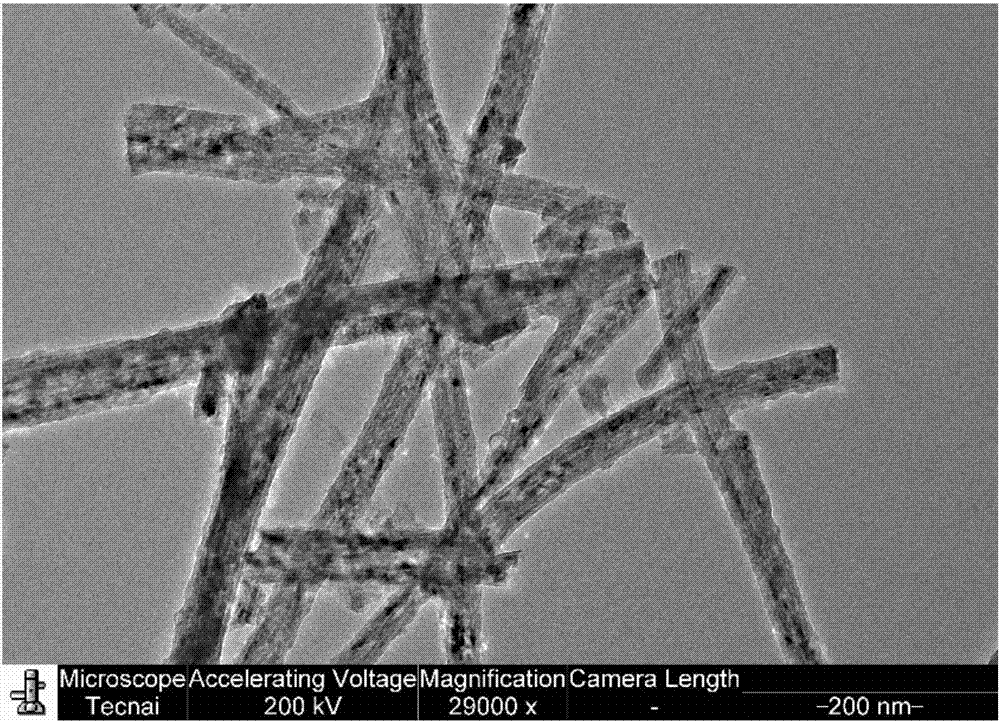

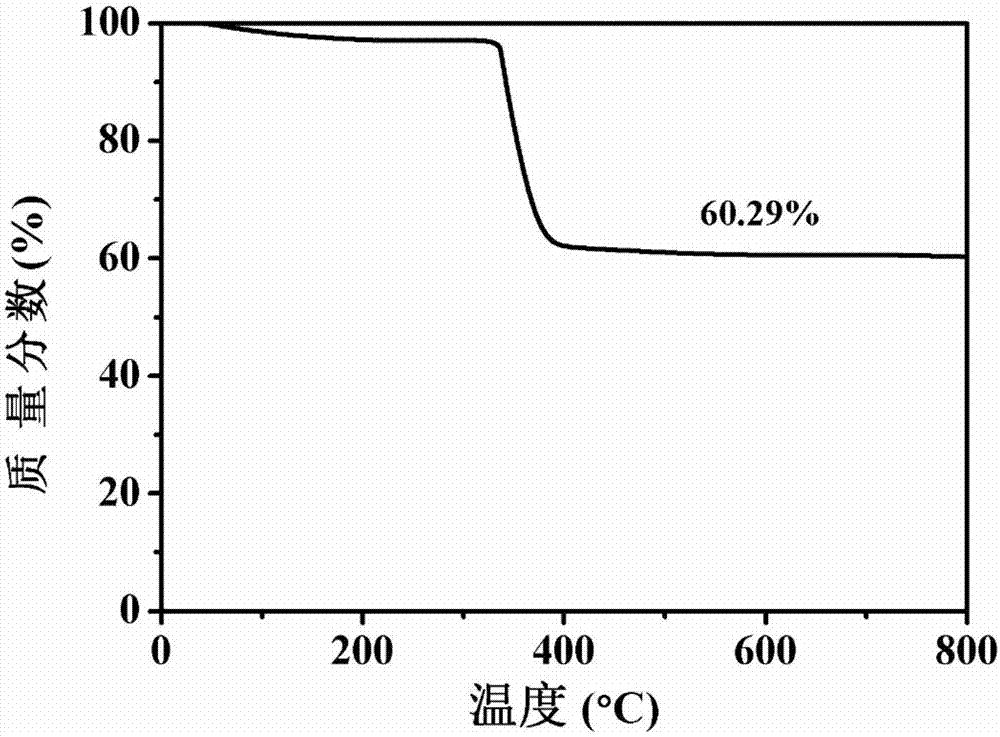

[0031] Preparation of electrospinning solution: Weigh 1g of polyvinylpyrrolidone and dissolve it in 10mL of absolute ethanol, stir at room temperature to obtain a uniform and transparent solution; add 2.5g of tetraethyl orthosilicate to the above transparent solution and stir evenly, then add 0.15g of Ultra-long manganese dioxide nanowires were stirred to obtain a uniformly dispersed slurry; wherein, the one-dimensional ultra-long manganese dioxide nanowires used were purchased from Beijing Tongguang Fine Chemical Co., Ltd. 0.316g potassium permanganate, Dissolve 0.74g of ammonium fluoride in 60ml of deionized water, then transfer the resulting solution to a 100ml polytetrafluoroethylene reactor, put the reactor in an oven at 200°C for hydrothermal reaction for 24 hours, and cool down to room temperature naturally. The obtained tan powder was washed with deionized water to neutrality and then dried at 80°C to obtain one-dimensional ultra-long manganese dioxide nanowires. (2) E...

Embodiment 2

[0033] Configuration of electrospinning solution: Weigh 1.5g of polyvinylpyrrolidone and dissolve it in 10.5mL of absolute ethanol (polyacetate pyrrolidone: absolute alcohol = 1:7), stir at room temperature to obtain a uniform and transparent solution; 5.25g of ethyl orthosilicate Ester (polypyrrolidone acetate: ethyl orthosilicate = 1:3.5) was added to the above transparent solution and stirred evenly, then 0.1g of one-dimensional ultra-long manganese dioxide nanowires were added, and stirred to obtain a uniformly dispersed slurry; (2) using Preparation of nanofiber membranes by electrospinning process: the parameters of the electrospinning process: the inner diameter of the syringe needle is 0.7mm, the temperature is 25°C, the relative humidity is 25%, the electrostatic voltage is 14kV, and the flow rate of the spinning solution is 1ml / h. The receiving distance is 25cm, the rotating speed of the drum is 400rpm, and double-needle spinning is used to obtain PVP / MnO 2 / TEOS fib...

Embodiment 3

[0035] Configuration of electrospinning solution: Weigh 1g of polyvinylpyrrolidone and dissolve it in 15mL of absolute ethanol, stir at room temperature to obtain a uniform and transparent solution; ) into the above-mentioned transparent solution and stir evenly, then add 0.05g of one-dimensional manganese dioxide nanotubes (active substance: polyvinylpyrrolidone=1:20), and stir to obtain a uniformly dispersed slurry; wherein, the used one-dimensional manganese dioxide Manganese nanotubes are obtained by dissolving 0.4g potassium permanganate and 0.1g concentrated hydrochloric acid purchased from Beijing Tongguang Fine Chemical Co., Ltd. in 50ml deionized water, and then transferring the resulting solution to a 100ml polytetrafluoroethylene reactor , put the reaction kettle in an oven at 140°C for hydrothermal reaction for 6 hours, cool down to room temperature naturally, wash the obtained tan powder with deionized water until it is neutral, and then dry it at 80°C to obtain on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com