Method for preparing oxygen-vacancy-containing strontium titanate photocatalyst

A catalyst, strontium titanate technology, applied in the field of preparation of strontium titanate hydrogen photocatalyst, can solve the problems of limited practical application and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Solvothermal preparation of SrTiO 3 .

[0024] Weigh 10mmol tetra-n-butyl titanate and dissolve it in 50mL ethylene glycol, stir it magnetically for 1h, and record it as solution A; weigh 10mmol strontium nitrate and dissolve it in 10mL H 2 O is recorded as solution B; solution B was slowly added dropwise to solution A, and continued to stir for 30 minutes to obtain a colloidal mixture C; slowly dripped 10 mL of NaOH aqueous solution (5.0 mol / L) into the colloidal mixture C, and continued to stir for 30 minutes to obtain a mixed solution d. Transfer the mixed solution D into a 100mL polytetrafluoroethylene liner, react in an autoclave at 180°C for 16h, wash with distilled water and ethanol several times, vacuum dry at 60°C, and grind to obtain SrTiO 3 .

[0025] (2) SrTiO 3 Photoreduction supported Pt (0.50wt%).

[0026] Weigh SrTiO 3 Sample 1.0 g, measure H 2 PtCl 6 Solution 13.3mL (1.93×10 -3 mol / L, Pt load 0.50wt%), added to 20mL of absolute ethanol and...

Embodiment 2

[0036] (1) SrTiO 3 The preparation is the same as in Example 1 step (1).

[0037] (2) SrTiO 3 Photoreduction supported Pt (1.0wt%).

[0038] Weigh SrTiO 3 Sample 1.0 g, measure H 2 PtCl 6 Solution 26.6mL (1.93×10 -3 mol / L, Pt load 1.0wt%), added to 20mL of absolute ethanol and ultrasonically dispersed for 20min, then irradiated with ultraviolet high-pressure mercury lamp for 2h under the protection of nitrogen, washed several times with distilled water and ethanol, vacuum-dried at 60°C, and ground to obtain Photoreduction of Pt / SrTiO with 1.0wt% Pt loading 3 .

[0039] (3)H 2 / N 2 Preparation of Pt / SrTiO by Mixed Gas Calcination 3-x Same as step (3) of Example 1.

[0040] (4) The photocatalytic hydrogen production performance test is the same as the step (4) of Example 1.

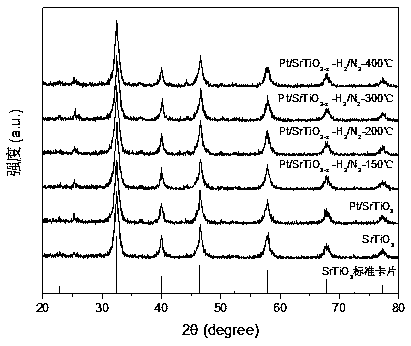

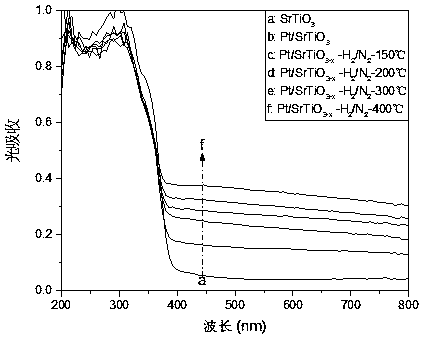

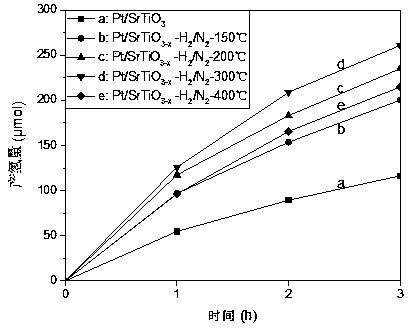

[0041] Figure 5 for H 2 / N 2 Pt / SrTiO prepared by calcination at different temperatures under mixed gas atmosphere 3-x XRD pattern. From Figure 5 It can be seen that strontium titanate ...

Embodiment 3

[0044] (1) SrTiO 3 The preparation is the same as in Example 1 step (1).

[0045] (2) NaBH 4 Chemical reduction of loaded Pt (0.50wt%).

[0046] Weigh SrTiO 3 Sample 1.0 g, measure H 2 PtCl 6 Solution 13.3mL (1.93×10 -3 mol / L, Pt loading 0.50wt%), added to 50mL distilled water and ultrasonically dispersed for 20min. Weigh NaBH 4 9.7 mg dissolved in 10mL distilled water (NaBH 4 with H 2 PtCl 6 The molar ratio is 10:1), slowly added dropwise to the above SrTiO 3 with H 2 PtCl 6 The mixed solution was magnetically stirred at room temperature for 4 h. Wash several times with distilled water and ethanol, vacuum dry at 60°C, and grind to obtain NaBH 4 Chemical reduction of Pt / SrTiO with Pt loading of 0.50wt% 3 .

[0047] (3)H 2 / N 2 Preparation of Pt / SrTiO by Mixed Gas Calcination 3-x With embodiment 1 step 3, calcining temperature is 200 ℃

[0048] (4) The photocatalytic hydrogen production performance test is the same as the step (4) of Example 1.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com