A kind of preparation method of high concealment ultraviolet light deep layer curing adhesive

A deep curing, ultraviolet light technology, applied in the direction of adhesives, polymer adhesive additives, microsphere preparation, etc., can solve the problems of reducing the curing depth, hindering the transmission of ultraviolet rays, etc., to achieve low shrinkage, excellent adhesion and mechanical properties. The effect of sex and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

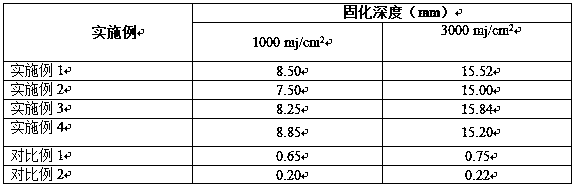

Examples

Embodiment 1

[0043] 55 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexylcarboxylate, 3.5 parts of triaryl sulfonium hexafluorophosphate, 0.5 part of N-vinylcarbazole, 1,2, 6 parts of 8,9-diepoxy-4-vinylcyclohexene and 4 parts of γ-aminopropyltriethoxysilane were added to the stirring tank, and the pressure was -0.1 MPa, stirred for 0.5 h, and added 25 parts of silicon micropowder and 1 part of irreversible color capsule, under the condition of pressure of -0.1 MPa, control the temperature not to be higher than 35 ℃, disperse at high speed for 0.6h, add 5 parts of meteorological silica, stir evenly, under the pressure of -0.1 MPa Under the condition, control the temperature not higher than 35 ℃, disperse and stir at a high speed for 1 hour, and then discharge the material, that is, to obtain a highly concealed UV light deep curing adhesive; the speed of the high-speed stirring is revolution 10-50 r / min, and rotation 600-2000 r / min.

[0044] The irreversible color capsule microparticl...

Embodiment 2

[0050] 30 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexylcarboxylate, 23 parts of bisphenol A epoxy resin, 3 parts of diaryl hexafluoroantimonate iodonium salt, 1- 0.5 parts of hydroxy-cyclohexyl-phenyl ketone, 10 parts of 3,3'-(oxybismethylene)bis(3-ethyl)oxetane and γ-aminopropyltriethoxysilane Add 3.5 parts into the stirring kettle, stir for 0.5h under the pressure of -0.1MPa, add 20 parts of silicon micropowder and 5 parts of irreversible color capsules, under the pressure of -0.1MPa, control the temperature not to be higher than 35 ℃, Disperse at high speed for 0.6h, add 5 parts of meteorological silica, stir evenly, under the condition of pressure of -0.1 MPa, control the temperature not to be higher than 35 ℃, disperse at high speed for 1h, and then discharge the material, that is to obtain high concealment UV light deep curing Adhesive; the rotational speed of the high-speed stirring is 10-50 r / min for revolution and 600-2000 r / min for autorotation.

[0051] Th...

Embodiment 3

[0057] 25 parts of bis-(3,4-epoxycyclohexylmethyl) adipate, 15 parts of hydrogenated bisphenol A epoxy resin, 3.5 parts of iodonium diaryl hexafluorophosphate, ( 2,4,6 - 0.5 parts of trimethylbenzoyl) diphenylphosphine oxide, 20 parts of 1,2,8,9-diepoxy-4-vinylcyclohexene and 3 parts of γ-aminopropyltriethoxysilane Add it to the stirring tank, stir for 0.5h under the pressure of -0.1 MPa, add 26 parts of silicon micropowder and 5 parts of irreversible color capsules, under the pressure of -0.1 MPa, control the temperature not to be higher than 35 ℃, and disperse at high speed 0.6h, add 2 parts of meteorological silica, stir evenly, under the condition of pressure of -0.1 MPa, control the temperature not to be higher than 35℃, disperse and stir at high speed for 1h, then discharge the material, that is to obtain a highly concealed UV light deep curing adhesive; The rotational speed of the high-speed stirring is 10-50 r / min for revolution and 600-2000 r / min for autorotation.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com