An Organic Salt Drilling Fluid with Enhanced Inhibition and Plugging Performance

A technology of plugging performance and organic salt, which is applied in the field of drilling fluid for oil drilling, can solve the problems of limited application range, plugging and surface hydration inhibition performance can not fully meet the development needs, and prominent surface hydration problems, etc. Achieve the effect of maintaining wellbore stability, inhibiting seepage hydration and surface hydration, and maintaining original strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

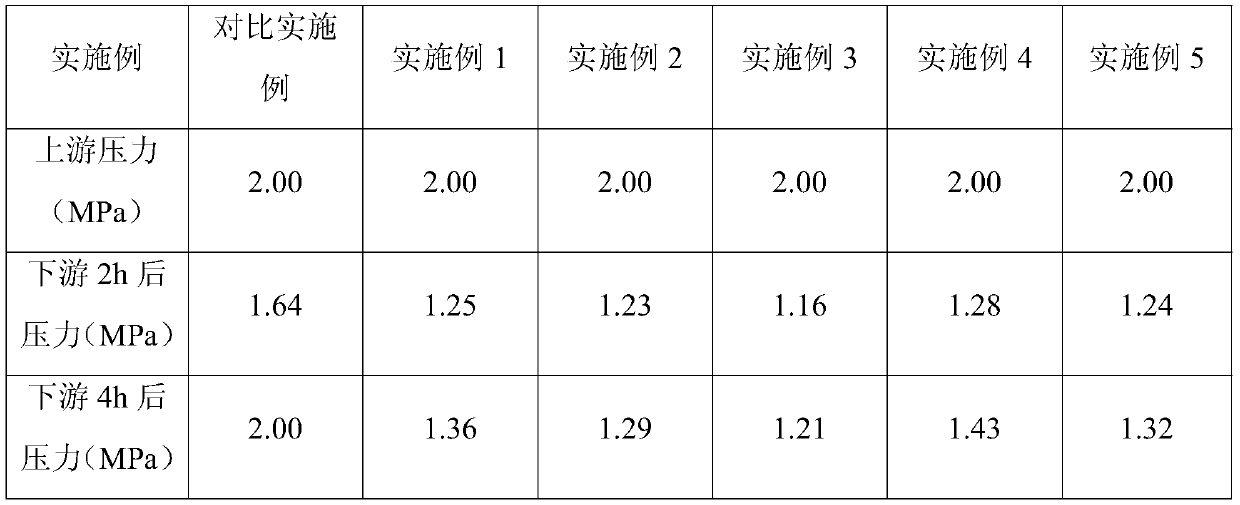

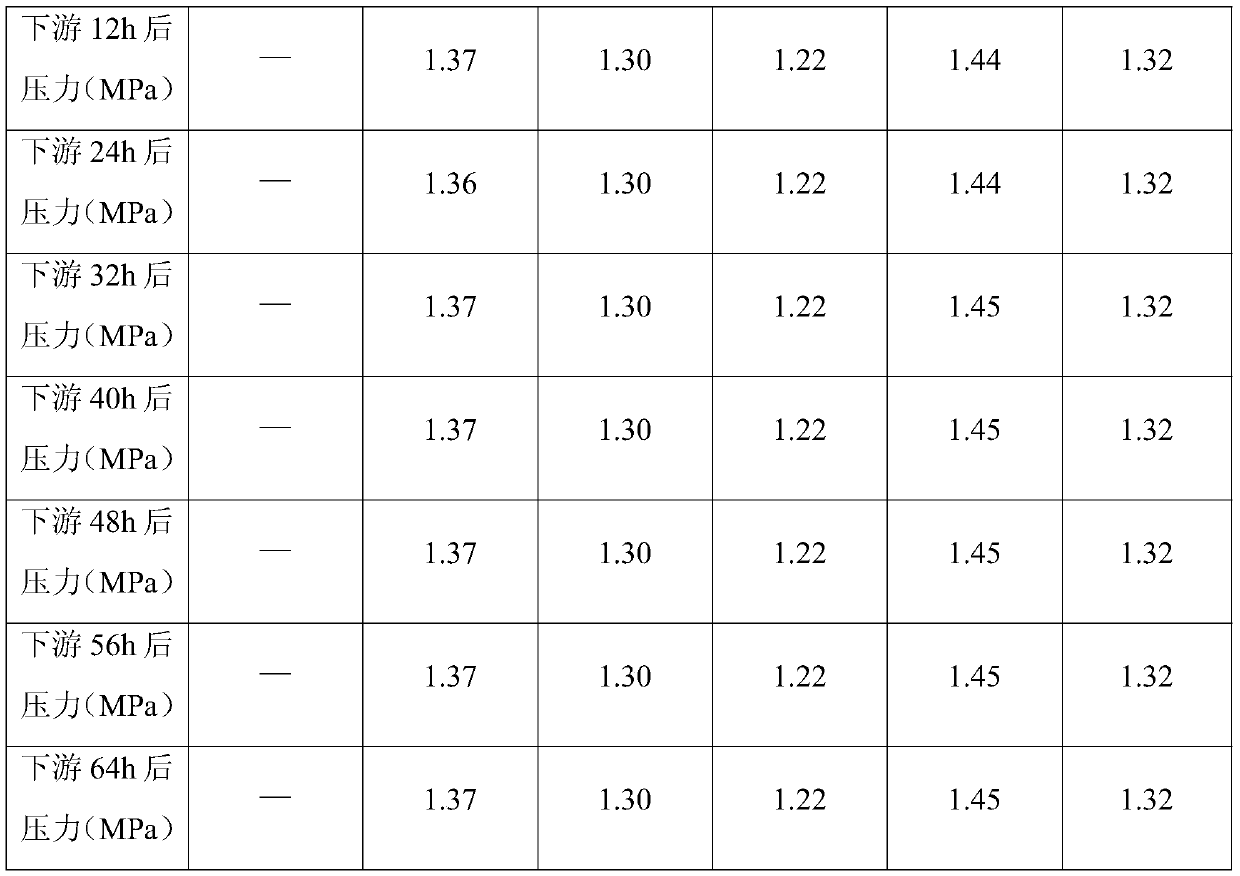

Examples

Embodiment 1

[0020] An organic salt drilling fluid system with enhanced inhibition and plugging performance, including 2% modified sepiolite, 0.3% soda ash, 60% potassium formate, 0.2% xanthan gum, 2% carboxymethyl cellulose, 1.5% White asphalt, 1% vinyl acetate-ethylene copolymer emulsion (D50 value 81nm), 1% nano silicon dioxide (particle size 54nm), 0.2% tetrafluorobutanediol, 0.5% polymer alcohol, 0.5% polyether Amine, 1% flake graphite, 3% superfine light calcium carbonate, 190% barite; the above percentages are based on the mass content of water. The superfine light calcium carbonate is compounded with 600 mesh, 1250 mesh and 2500 mesh according to the mass ratio of 1:1:1. The drilling fluid is prepared according to the method described in the present invention under high-speed stirring.

Embodiment 2

[0022] An organic salt drilling fluid system with enhanced inhibition and plugging performance, including 4% attapulgite, 0.4% soda ash, 30% sodium formate, 0.5% Velan gum, 0.5-2% polyanionic cellulose, 2% sulfonated Asphalt, 2% vinyl acetate-ethylene copolymer emulsion (D50 value 81nm), 1% styrene-butadiene emulsion (D50 value 90nm), 0.4% pentafluoropropanol, 1.5% polymer alcohol, 1% polyether amine, 2 % flake graphite, 5% superfine light calcium carbonate, 220% barite; the above percentages are based on the mass content of water. The superfine light calcium carbonate is compounded with 600 mesh, 1250 mesh and 2500 mesh according to the mass ratio of 1:1:2. The drilling fluid is prepared according to the method described in the present invention under high-speed stirring.

Embodiment 3

[0024] An organic salt drilling fluid system with enhanced inhibition and plugging performance, including 3% modified sepiolite, 0.5% soda ash, 30% potassium formate, 30% sodium formate, 0.4% chitosan, 0.5% carboxymethyl fiber element, 1% polyanionic cellulose, 4% white pitch, 1% vinyl acetate-ethylene copolymer emulsion (D50 value 81nm), 1% styrene-butadiene emulsion (D50 value 90nm), 1% polycarbonate emulsion ( D50 value is 65nm), 1% nano-silica (particle size is 54nm), 0.4% tetrafluorobutanediol, 2.5% polymer alcohol, 1% polyether amine, 2% flake graphite, 4% ultra-fine light weight Calcium carbonate, 260% barite; the above percentages are based on the mass content of water. The superfine light calcium carbonate is compounded with 600 mesh, 1250 mesh and 2500 mesh according to the mass ratio of 1:1:1. The drilling fluid is prepared according to the method described in the present invention under high-speed stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com