Preparation and application of novel color changing fiber APF-PAR

An APF-PAR, chromogenic fiber technology, applied in the field of chelating fiber synthesis, can solve the problems of high cost and high detection cost, and achieve the effects of reducing detection cost, fast adsorption speed and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Accurately weigh 0.15g of parent acrylic fiber (PAN) and place it in a 100ml three-neck bottle, then add 30ml of reaction solvent water, soak and swell for 6h;

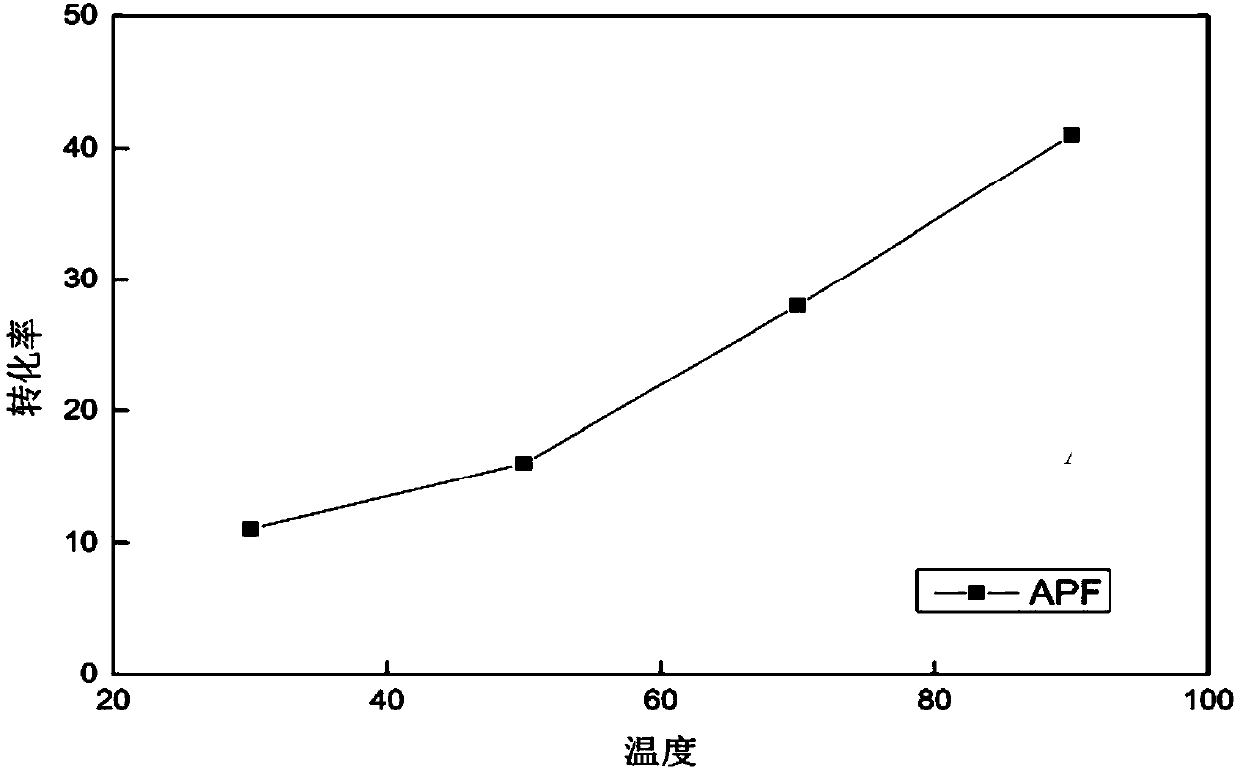

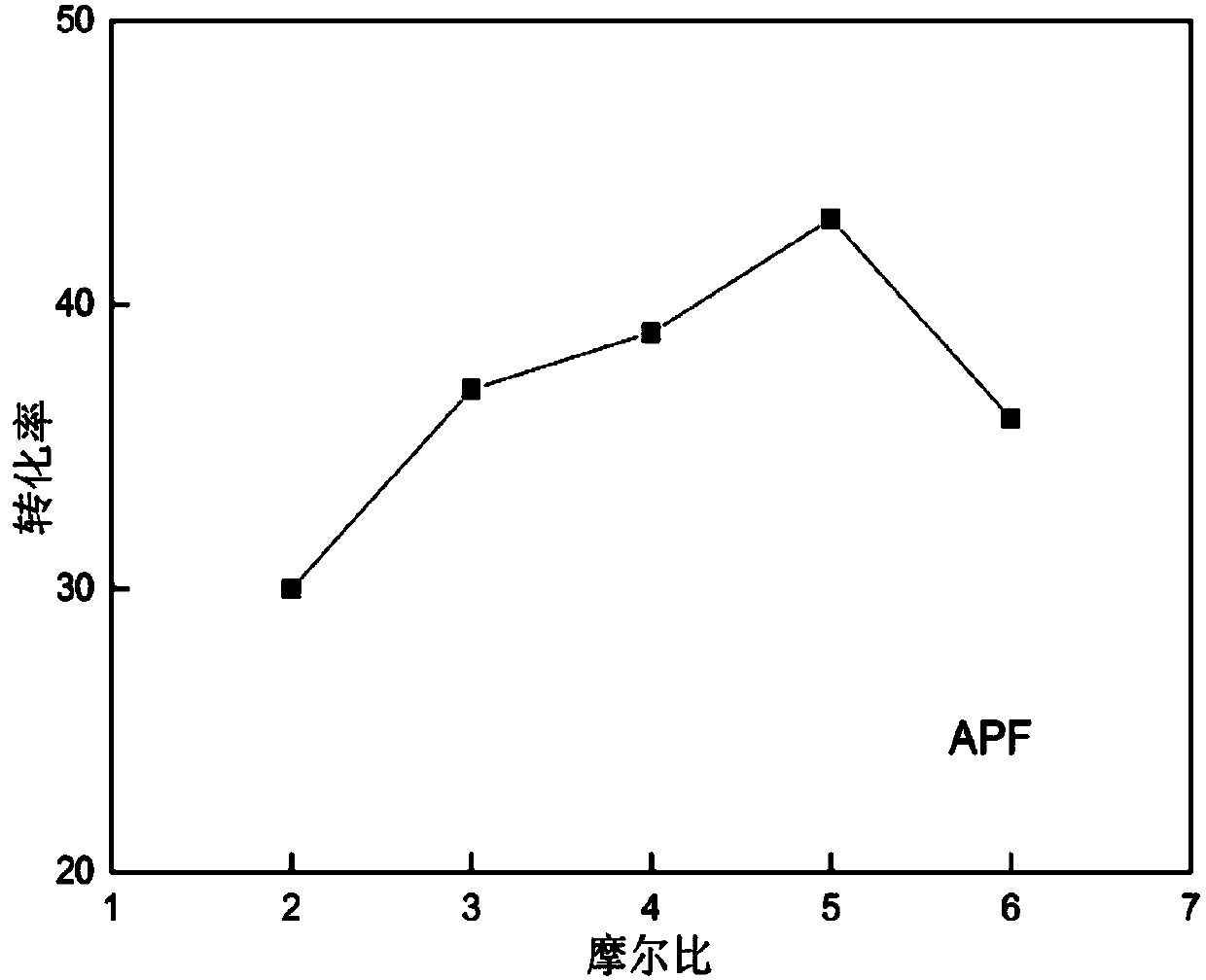

[0052] (2) Add ligand 1-(2 aminoethyl) piperidine in the three-necked bottle, and connect nitrogen, stir 1-2h at normal temperature with the stirring speed of 150rpm, after the air in the bottle is exhausted (i.e. Under nitrogen protection conditions), stirred at 90°C until the reaction was completed, wherein the molar ratio of acrylic fiber (matrix) to 1-(2 aminoethyl)piperidine (ligand) was 1:5;

[0053] (3) After the reaction in step (2) is finished, wash the product of step (2) with water until the reaction solvent is colorless, then wash it several times with absolute ethanol, acetone, and ether, and dry it under vacuum at 50°C To constant weight, obtain acrylic fiber chelating fiber APF.

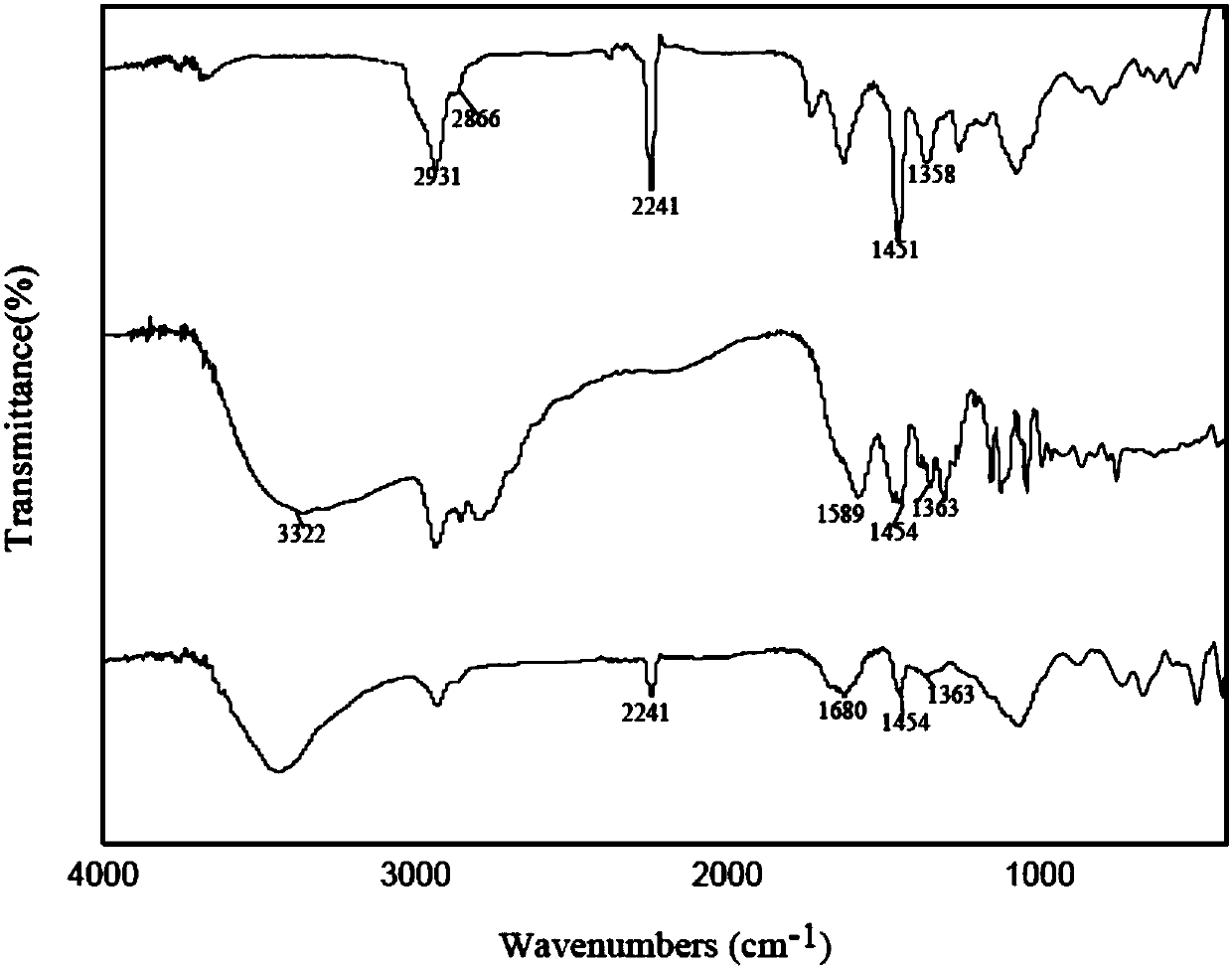

[0054] figure 1 Shown is the infrared spectrogram of the APF prepared by embodiment 1; 2241m-1 peak is the stre...

Embodiment 2

[0095] Put 0.5g of acrylic chelate fiber APF, 0.3g of PAR, 35mL of water and 5mL of formaldehyde solution into a 100mL three-neck flask, stir and heat to reflux for 4 hours under the protection of nitrogen, and complete the reaction at 70°C, take out the fiber, and rinse the fiber repeatedly with warm water To neutral, dry in an oven (50°C) for 2 hours to obtain the color-developing fiber APF-PAR. At room temperature, place the chromogenic fiber APF-PAR in various heavy metal ion solutions to observe the chromogenic effect. Wherein, the heavy metal ion solution includes Pb 2+ , Zn 2+ 、 Cu 2 + 、Ni 2+ , Hg 2+ 、Cd 2+ .

[0096] Such as Figure 7 As shown, the chromogenic fiber APF-PAR pair 10 -2 mol / L of Pb 2+ , Zn 2+ 、Cu 2+ 、Ni 2+ , Hg 2+ 、Cd 2+ Six heavy metals were used for color development, and we can clearly see that under the condition of pH 6, the color development fiber APF-PAR has a positive effect on Cu 2+ , Hg 2+ All have obvious color rendering effec...

Embodiment 3

[0126] (1) Preparation of acrylic chelating fiber APF: the specific process is as in the preparation process of APF in Example 1.

[0127] (2) Preparation of chromogenic fiber APF-PAR: the specific process is as the preparation process of APF-PAR in Example 2.

[0128] (3) Pretreatment of the sample to be tested: Weigh 0.5 g of the mashed and homogenized tuna sample and place it in a polytetrafluoroethylene tube, add 1 mL of 30% H 2 o 2 , 10mL HNO 3 , and then put it into the digestion tank, put it in the digestion instrument, and set the digestion conditions: 800w, 15min; 1000w, 25min; 0w, 15min. After digestion, take out the polytetrafluoroethylene tube and put it on the electric heating plate, heat at 120°C for 2 hours, drain the acid until about 1mL of the digestion solution remains, transfer it into a volumetric flask, and dilute it to 25mL with deionized water for testing.

[0129] (4) Submerge the APF-PAR acrylic fiber prepared by masking in the colorimetric tube com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com