Metal grid structure and formation method thereof

A metal gate and gate technology, applied in the field of metal gate structure and its formation, can solve the problems of oxide layer erosion and device leakage of devices, reduce the risk of fluorine erosion, improve performance, and reduce the risk of fluorine residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

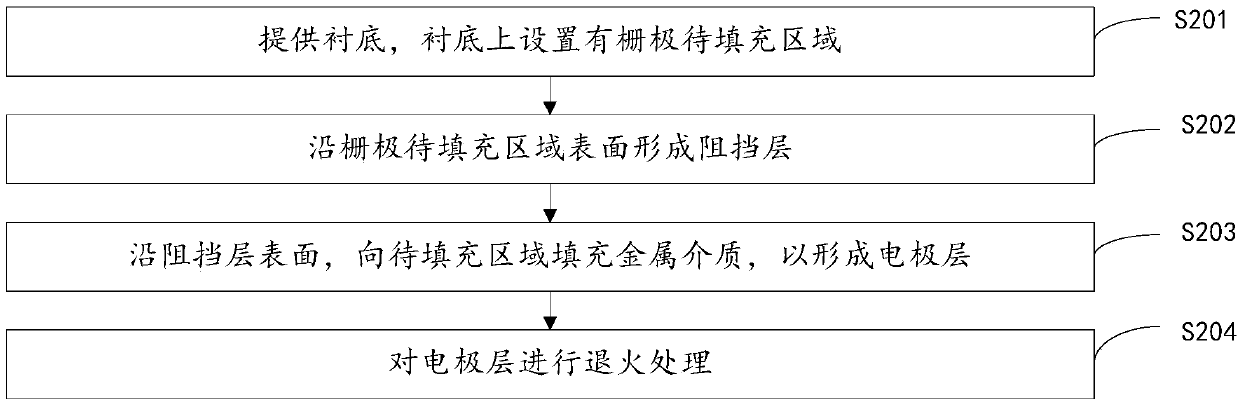

[0032] Embodiments of the present application are described below in conjunction with the accompanying drawings.

[0033] In the field of semiconductors, metal tungsten is often used to form metal gates due to its good resistance to electromigration and corrosion resistance. However, a gate formed by a chemical vapor deposition (Chemical Vapor Deposition) CVD process or an ALD process often has voids. The presence of such voids or voids greatly affects the performance of semiconductor devices.

[0034] The following is combined with the process of filling metal tungsten by CVD process to illustrate the principle of void generation and how voids affect device performance.

[0035] As the integration level of semiconductor devices becomes higher and higher, the feature size of the devices becomes smaller and smaller. The feature size can be understood as the line width of the integrated circuit, which is generally equal to the minimum width of the channel. The width of the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com