High-molecular mask plate and manufacturing method and application thereof

A production method and technology of polymer film layer, which are applied in ion implantation plating, photoengraving process of pattern surface, and instruments, etc., can solve the problems of damage to the evaporation substrate, changes in tension, pollution, etc., to achieve The production process is fast and convenient, the effect of avoiding tension and high production precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

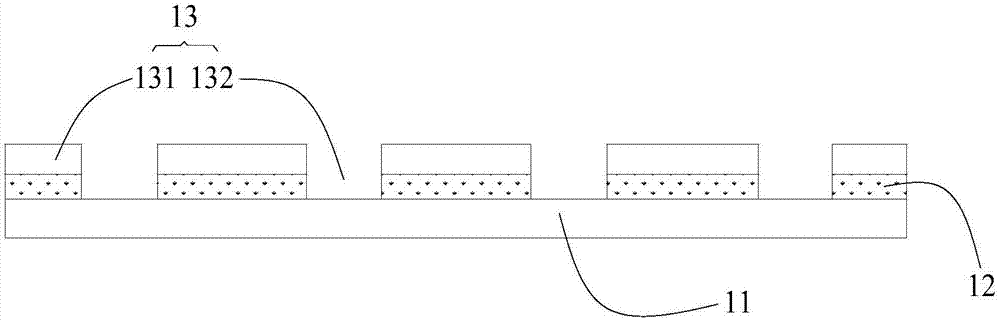

[0043] This embodiment provides a polymer mask, specifically refer to figure 1 , the polymer mask plate includes a carrier substrate 11 and a sacrificial layer 12 and a mask 13 sequentially laminated on the carrier substrate 11; wherein, the mask 13 includes a polymer film layer 131 and a polymer layer 131 On and through several holes 132 of the polymer film layer 131 , the polymer film layer 131 is doped with magnetic nanoparticles (not shown in the figure).

[0044] Specifically, the thickness of the polymer film layer 131 is generally controlled to be 5 μm to 50 μm, and its material can be selected from polyimide (abbreviated as PI), polypropylene (abbreviated as PP), polystyrene (abbreviated as PS), polysulfone Any one of ether (abbreviated as PES), graphene or its modified material, polyethylene terephthalate (abbreviated as PET); in this embodiment, PI is preferably used as the material of the polymer film layer 131 .

[0045] More specifically, the thickness of the sac...

Embodiment 2

[0062] This embodiment provides a method for manufacturing OLEDs, that is, using the polymer mask obtained in Example 1 to manufacture OLEDs, which specifically includes the following steps:

[0063] Step 1: On the substrate 311, the anode 312 and the hole transport layer 313 are sequentially laminated to form the evaporation substrate 31; Figure 6 shown.

[0064] Preferably, in order to facilitate subsequent fabrication of light-emitting layers of different colors, different pixel regions are separated by pixel definition layers 314 .

[0065] The manufacturing method of the evaporation substrate 31 can refer to the prior art, and will not be repeated here.

[0066] Step 2: Form a red light emitting layer 321 , a green light emitting layer 322 and a blue light emitting layer 323 by vapor deposition on the evaporation substrate 31 .

[0067] Specifically, the following steps are included:

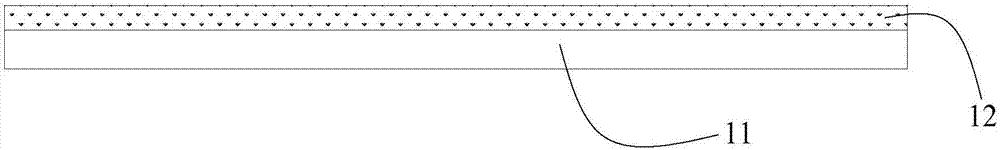

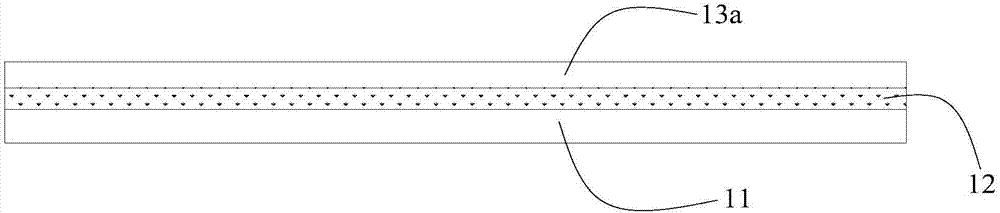

[0068] Q1, making a sacrificial layer 12 on the carrier substrate 11; as Figure 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com