Conductive slurry and method of using same to form net shaped carbon thermo-conductive electroconductive network current collector

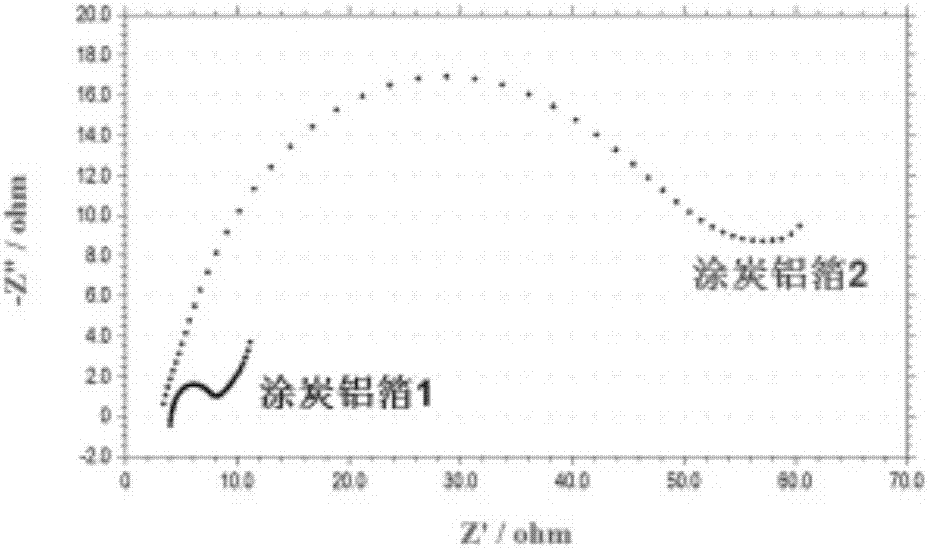

A technology of conductive paste and conductive network, which is applied in the field of energy storage systems, can solve problems such as poor conductive properties, high cost, and incomplete carbon film coating, and achieve the effect of avoiding thermal aging problems and improving system life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

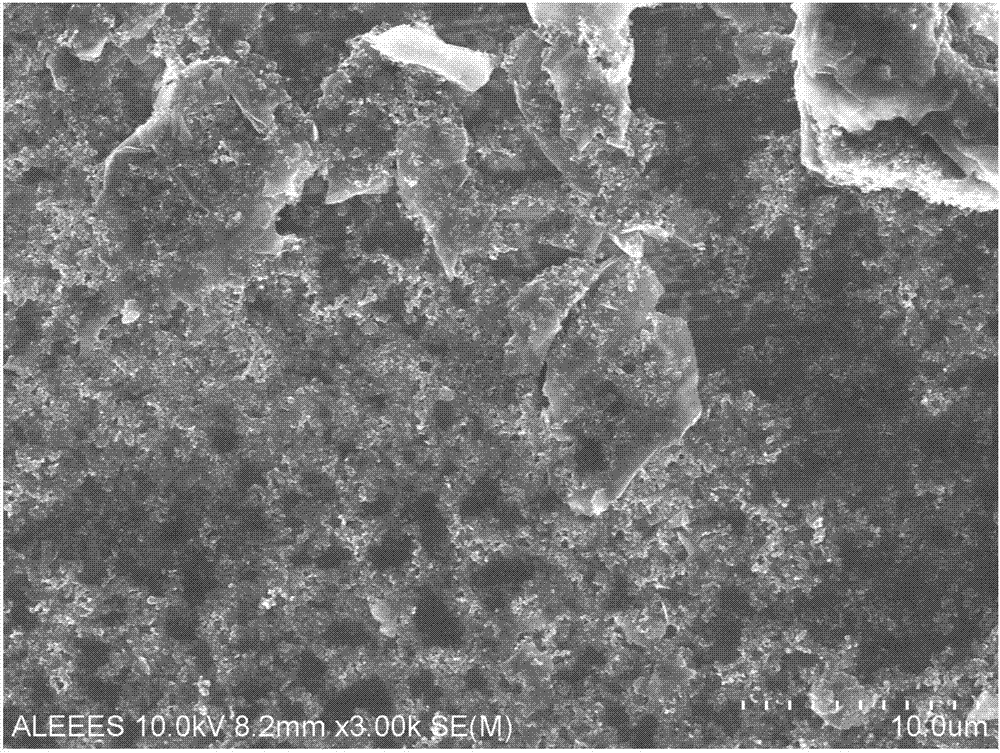

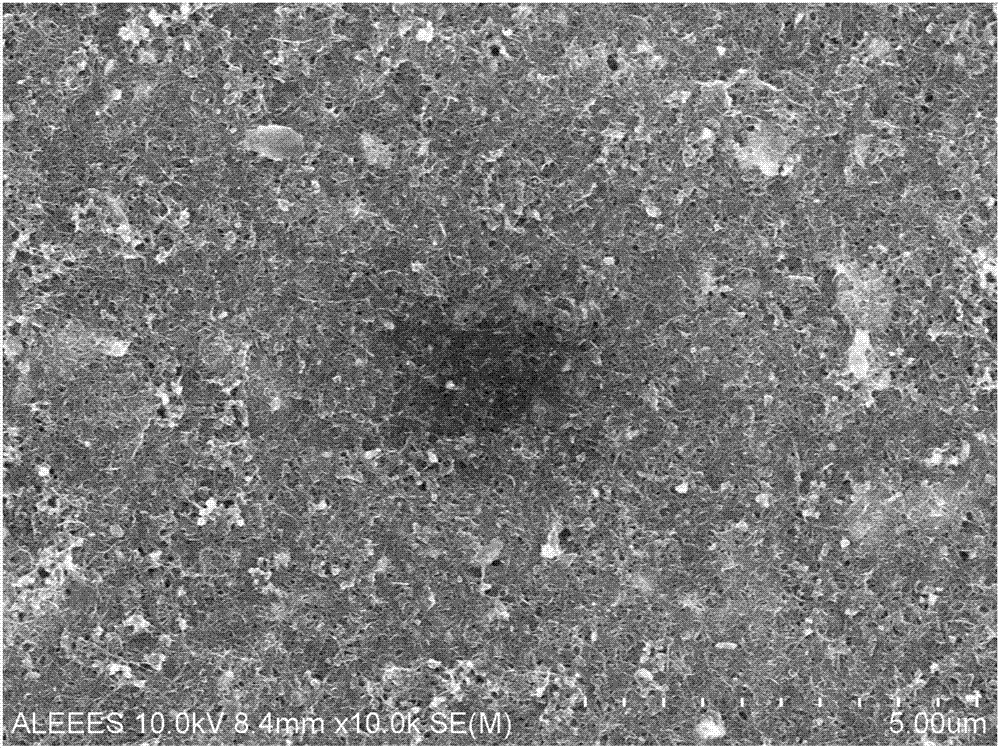

[0028] After mixing 5g of carbon nanotubes, 10g of conductive carbon black, and 2g of flake graphite, soak them in 500ml of 1M hydrochloric acid for pickling for 5 hours, filter the solution of the carbon slurry material, and dissolve the pickled carbon material in water and add 20 g of ethylenediamine was mixed with a ball mill for 5 hours. After mixing, the carbon slurry was heated at 140° C. for 1 hour to carry out cross-linking reaction. After the reaction was completed, excess ethylenediamine was washed away by washing with water three times, and 20 g of PVA (polyvinyl alcohol) was added to dissolve into a carbon slurry with a carbon solid content of 10%, and ultrasonically dispersed for 1 hour to complete the slurry treatment. Coat the slurry on a 20um aluminum foil, control the thickness of the carbon film between 1 and 2um, and bake in an oven at 90°C to complete the carbon-coated aluminum foil.

Embodiment 2

[0030] 4g of carbon nanotubes, 1g of graphene, 10g of conductive carbon black, and 2g of flake graphite are mixed and soaked in 500ml of 1M hydrochloric acid for pickling for 5 hours. After adding 20 g of ethylenediamine to water, it mixed with a ball mill for 5 hours. After mixing, the carbon slurry was heated at 140° C. for 1 hour to carry out cross-linking reaction. After the reaction was completed, the excess ethylenediamine was washed away by washing three times with water, and 20 g of methylcellulose was added to dissolve the carbon slurry with a carbon solid content of 10% for ultrasonic dispersion for 1 hour to complete the slurry treatment. Coat the slurry on a 20um aluminum foil, control the thickness of the carbon film between 1 and 2um, and bake in an oven at 90°C to complete the carbon-coated aluminum foil.

Embodiment 3

[0032] Soak 5g of carbon nanotubes in 400ml of 1M hydrochloric acid for pickling for 5 hours. At the same time, mix 10g of conductive carbon black and 2g of flake graphite and soak in 400ml of 1M sodium hydroxide for pickling for 5 hours. Filter the two carbon slurry materials separately. Wash off the excess acid-base solvent three times. The two filtered carbon materials were prepared into an aqueous solution with a solid content of 10%, and 20 g of PVA (polyvinyl alcohol) was added to dissolve the carbon slurry, and the carbon slurry was ultrasonically dispersed for 1 hour to complete the slurry treatment. Coat the slurry on a 20um aluminum foil, control the thickness of the carbon film between 1 and 2um, and bake in an oven at 90°C to complete the carbon-coated aluminum foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com