Preparation method of nickel sulfate coated ferriferrous oxide particle for iron-nickel battery

A technology for ferroferric oxide and iron-nickel batteries, which is applied in the direction of nickel storage batteries, battery electrodes, alkaline storage batteries, etc., and can solve the problems of limited electrochemical performance improvement, reduced discharge capacity, high rate performance and increased nickel sulfide deposition, etc. , to increase the activation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

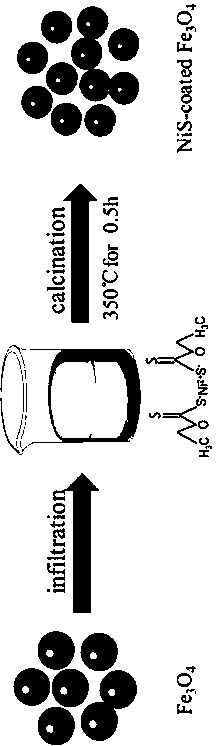

[0021] Commercial battery-grade ferric oxide powder is selected as the coating matrix, and the particle size is 0.3-1.5 μm. Prepare 20mL1mol / L sodium ethyl xanthate (C 2 h 5 OCS 2 Na) solution and 10mL 1mol / L nickel sulfate solution, first add sodium ethyl xanthate solution into a 100mL reaction flask, slowly add nickel sulfate solution under stirring, the reaction temperature is room temperature, and the precipitate generated by the reaction is filtered, washed and Dry to obtain 2.8g powdery nickel ethyl xanthate ((C 2 h 5 OCS 2 ) 2 Ni); Weigh 1g powdered nickel ethyl xanthate and dissolve it in 10mL pyridine to obtain 10mL 0.1g / mL nickel ethyl xanthate pyridine solution. The mass ratio of the three irons is calculated as 2:98, weigh 14.8g of the ferric oxide powder; add 10mL of 0.1g / mL nickel pyridine ethyl xanthate solution dropwise to the 14.8g of the ferric oxide powder and stir to mix evenly Obtain the ferroferric oxide intermediate impregnated with ethyl xanthate...

Embodiment 2

[0023] According to example 1 operation step, sodium ethyl xanthate (C 2 h 5 OCS 2 Na) was changed to potassium isopropylxanthate (C 3 h 7 OCS 2 K), change nickel sulfate into nickel chloride, and react to obtain 3.1g nickel isopropyl xanthate ((C 3 h 7 OCS 2 ) 2 Ni); Weigh 1g of nickel isopropylxanthate and dissolve it in 1mL of pyridine to obtain 1mL of 1.0g / mL nickel ethylxanthate in pyridine. The mass ratio of 4:96 is calculated, weighing 6.62g of ferric oxide powder; 1mL of 1.0g / mL nickel pyridine ethyl xanthate solution is added dropwise to 6.62g of ferric oxide powder, stirred and mixed evenly to obtain a surface The ferric oxide intermediate impregnated with the nickel pyridine solution of alkyl xanthate is placed in a high-temperature furnace and heat-treated at 350°C for 1 hour in an air atmosphere to obtain ferric oxide particles coated with nickel sulfide. The average particle size of the nickel sulfide layer is 120nm, the average thickness of the nickel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com