Preparation method of rare-earth element doped modified hollow microsphere bismuth oxyiodide photocatalyst

A rare earth element, bismuth iodide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve complex and diverse pollutants that cannot be completely degraded, and difficult to degrade by microbial methods. It can achieve good application prospects, improved photocatalytic degradation performance, and high reusability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

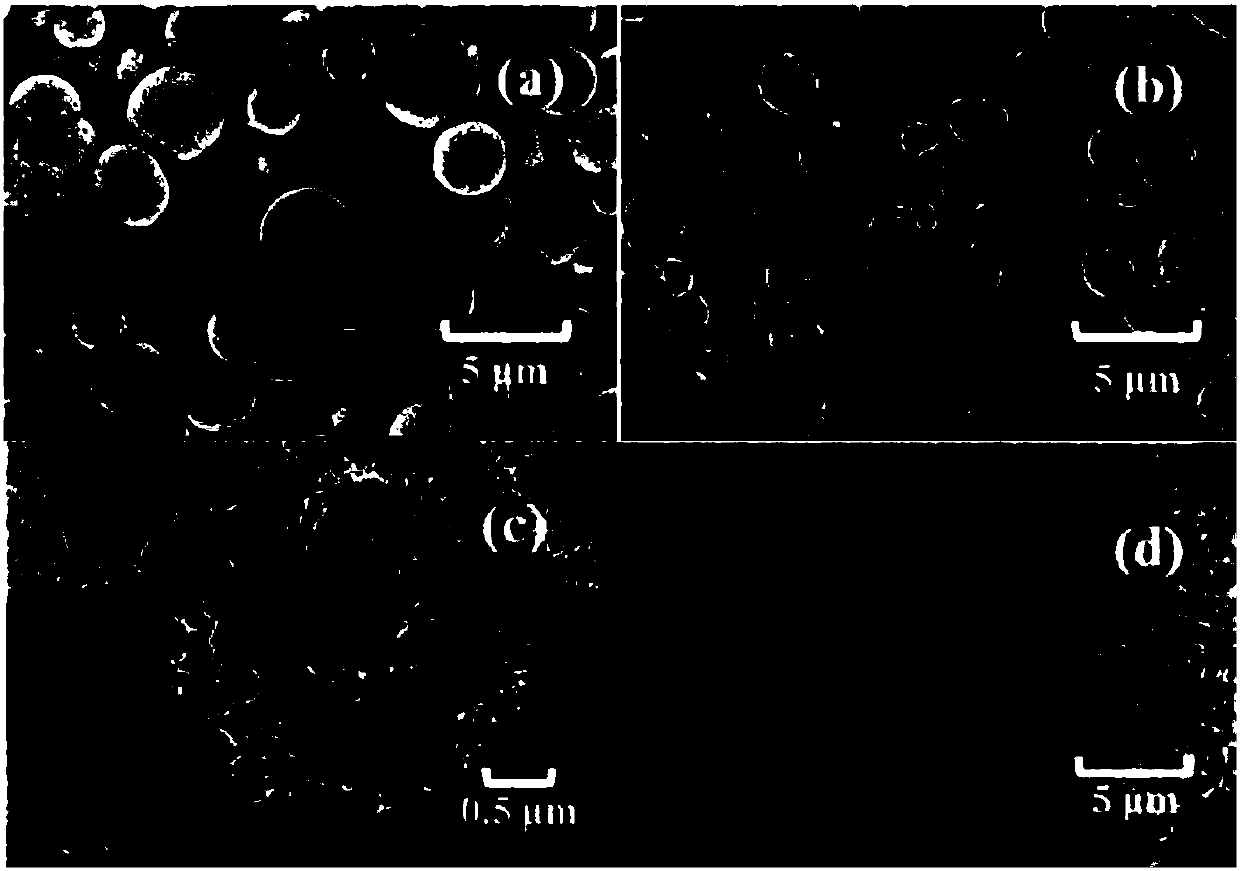

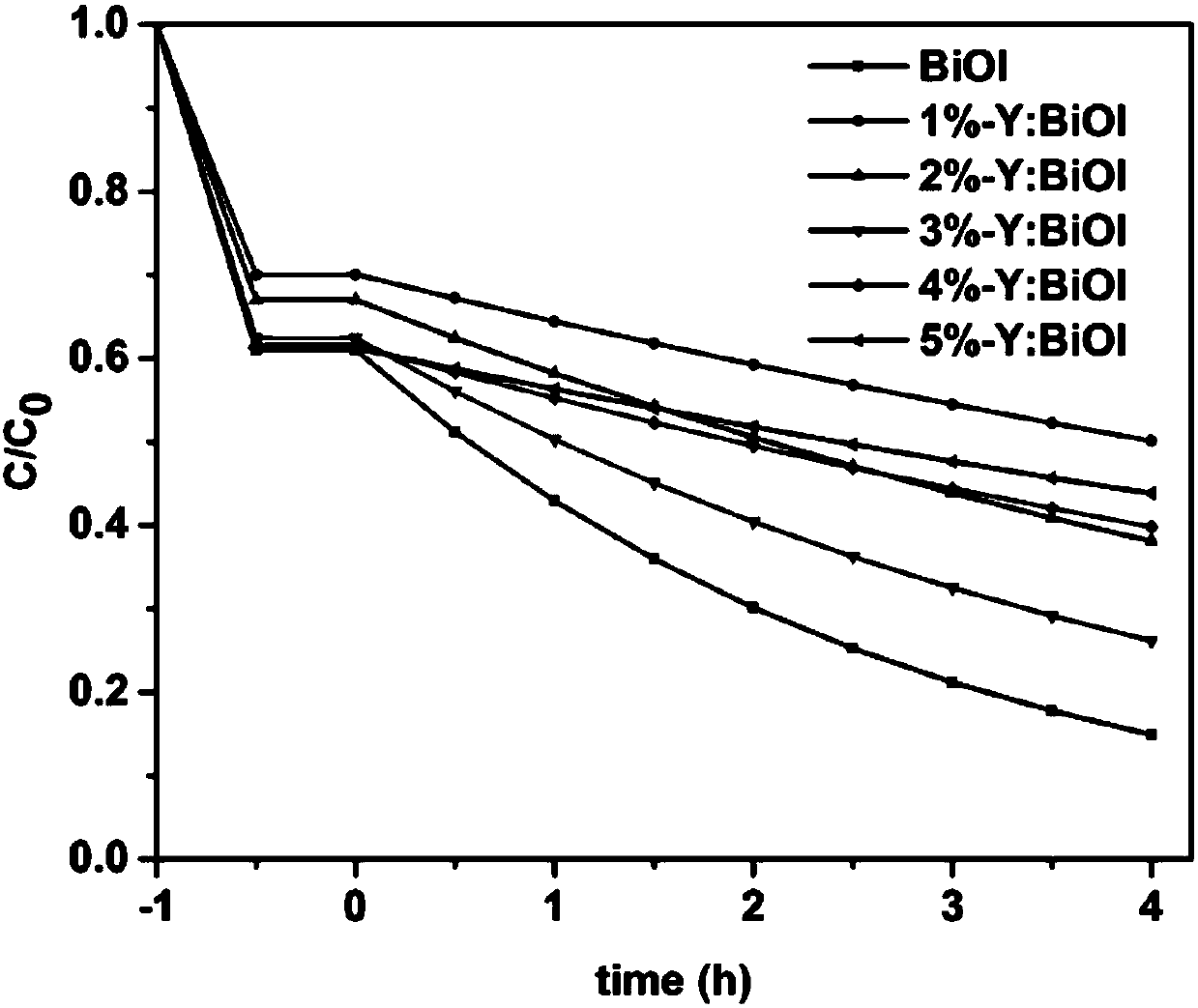

[0033] (1) 0.002mmol bismuth nitrate pentahydrate was mixed with 0% (as a control group), 1%, 2%, 3%, 4%, 5% (Y 3+ Bi 3+ molar ratio) of the yttrium element nitrate mixed into 20mL ethylene glycol solvent, magnetic stirring (60rpm) 3h, fully dissolved, to obtain 5 groups of bismuth nitrate solutions containing yttrium element with different contents.

[0034] (2) Add 0.002 mmol of potassium iodide into 20 mL of ethylene glycol solvent, stir magnetically (60 rpm) for 1 hour, and fully dissolve to obtain a potassium iodide solution.

[0035] (3) under magnetic stirring (60rpm), the potassium iodide solution obtained by step (2) is added dropwise at a constant speed (3 drops / second) to the bismuth nitrate solution containing yttrium element in different contents obtained by step (1), drop After the addition, continue magnetic stirring for 0.5h to obtain the precursor solution, put it in a polytetrafluoroethylene high-temperature reactor and react at 120°C for 12h, with a heating...

Embodiment 2

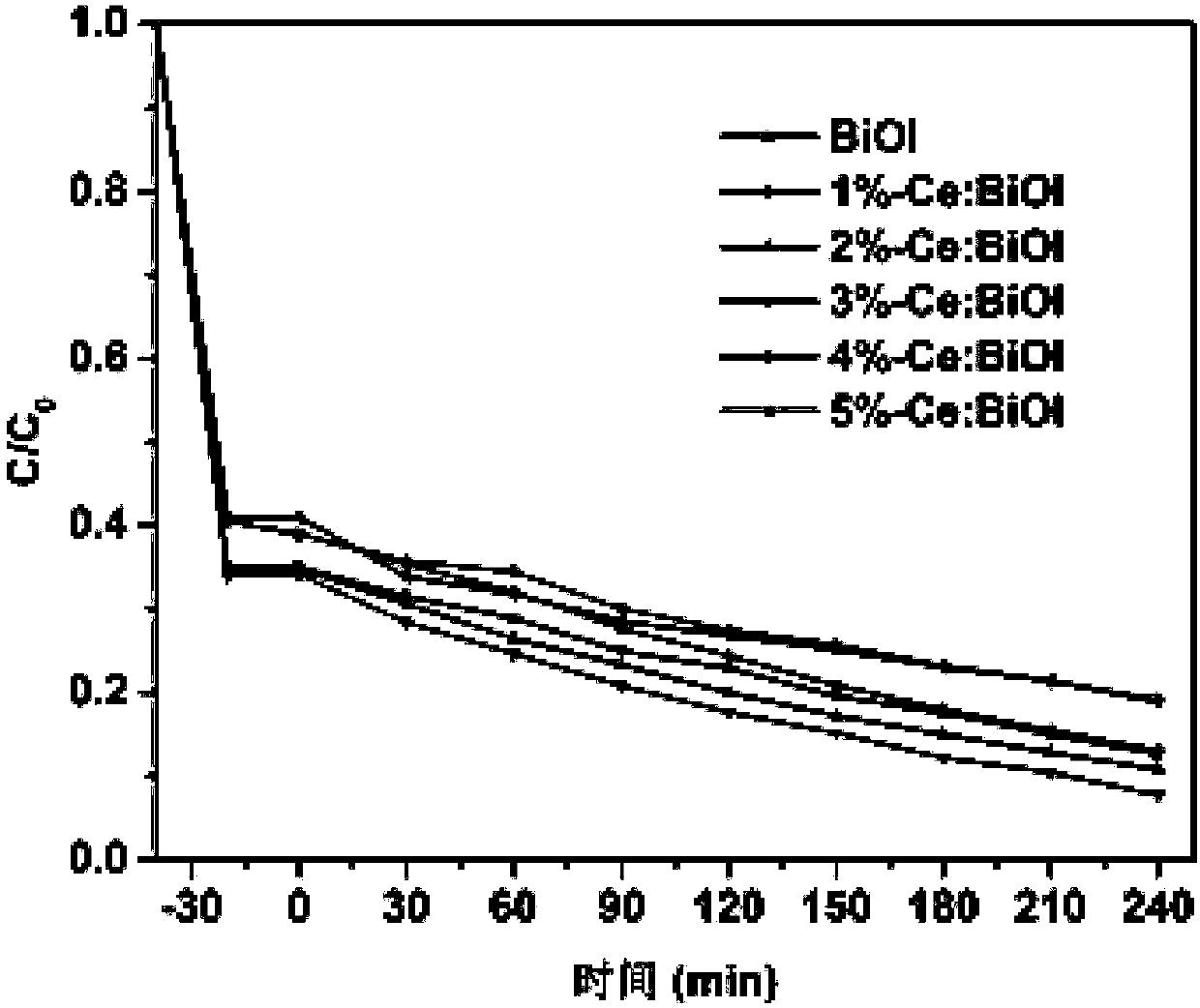

[0038] (1) 0.002mmol bismuth nitrate pentahydrate was mixed with 1%, 2%, 3%, 4%, 5% (Ce 3+ Bi 3+ molar ratio) of cerium nitrate mixed with 20mL ethylene glycol solvent, magnetic stirring (60rpm) 3h, fully dissolved, to obtain 5 groups of bismuth nitrate solutions containing cerium with different contents.

[0039](2) Under magnetic stirring (60rpm), the potassium iodide solution obtained in step (2) of embodiment 1 is added dropwise at a constant speed (3 drops / second) to the bismuth nitrate solution containing cerium element in different contents obtained in step (1) After the dropwise addition, continue magnetic stirring for 0.5h to obtain the precursor solution, place it in a polytetrafluoroethylene high-temperature reactor and react at 120°C for 12h, with a heating rate of 5°C / min, and naturally cool down to room temperature after the reaction and take it out , washed three times with ethanol and water respectively, dried in a vacuum oven at 60°C for 12 hours, and ground ...

Embodiment 3

[0042] (1) 0.002mmol bismuth nitrate pentahydrate was mixed with 1%, 2%, 3%, 4%, 5% (Pr 3+ Bi 3+ The nitrate of the praseodymium element) is mixed and added in 20mL ethylene glycol solvent, magnetically stirred (60rpm) for 3h, fully dissolved, and 5 groups of bismuth nitrate solutions containing praseodymium element with different contents are obtained.

[0043] (2) under magnetic stirring (60rpm), the potassium iodide solution obtained in embodiment 1 step (2) is added dropwise at a constant speed (3 drops / second) to the bismuth nitrate solution containing praseodymium element in different contents obtained in step (1) After the dropwise addition, continue magnetic stirring for 0.5h to obtain the precursor solution, place it in a polytetrafluoroethylene high-temperature reactor and react at 120°C for 12h, with a heating rate of 5°C / min, and naturally cool down to room temperature after the reaction and take it out , washed three times with ethanol and water respectively, dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com